A pH-responsive silicone foam with an interpenetrating network

An organosilicon foam, interpenetrating network technology, used in polymer materials and petrochemical fields, can solve the problems of easy rupture, unsatisfactory durability, and reduced oil-water separation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 24g of vinyl-terminated polydimethylsiloxane with a viscosity of 5000cs, 16g of vinyl MQ resin, 46g of dimethylaminoethyl methacrylate, 4g of ethylene glycol dimethacrylate and 2g of di-tert-butyl peroxide Mix the mixture evenly and add it to the sodium chloride powder. After the air bubbles in the sodium chloride powder are completely removed, seal it and react at 170°C for 2 hours, then use water to dissolve the sodium chloride to obtain a silicone foam. The 60% deformation compressive strength of silicone foam is 0.50MPa.

[0025] pH responsiveness: prepare a hydrochloric acid aqueous solution with a pH of 1, immerse the prepared silicone foam in the hydrochloric acid aqueous solution, the silicone foam changes from the initial hydrophobic state to a hydrophilic state, drop oil droplets (1,2-dichloro ethane), it will be in a super-oleophobic state in water; when the silicone foam is immersed in neutral water (pH=7) or alkaline water (pH>7), the foam will be in a hydr...

Embodiment 2

[0038] 60g of polyvinyl polydimethylsiloxane with a vinyl content of 3% and a viscosity of 10000cs, 70g of dimethylaminoethyl methacrylate, 5g of ethylene glycol dimethacrylate and 1g of di-tert-butyl peroxide The oxides are mixed evenly, and added to the sodium chloride powder. After the air bubbles in the sodium chloride powder are completely removed, seal it, react at 130°C for 10 hours, and then use water to dissolve the sodium chloride to obtain a silicone foam.

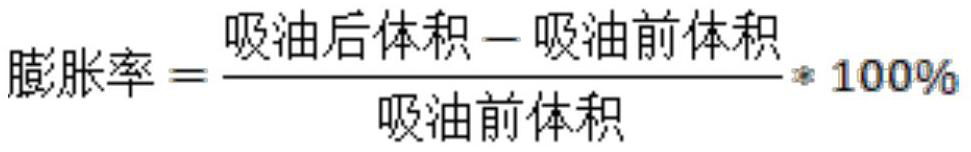

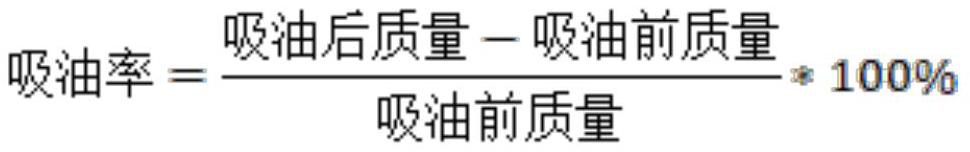

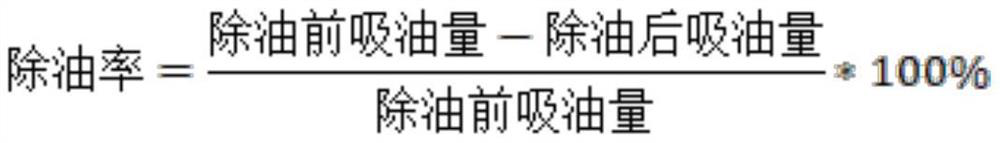

[0039]Oil-water separation experiment: Pour 50g of water and 50g of n-hexadecane into a beaker. The silicone foam is placed at the oil-water interface, and the n-hexadecane is quickly absorbed. After taking it out, measure the size of the silicone foam, and the expansion rate is 0%. The oil absorption rate is 98%, and after extrusion and washing with pH=1, the oil removal rate is 93%. The 60% deformation compressive strength of silicone foam is 0.11MPa.

Embodiment 3

[0041] 50g of polyvinyl polydimethylsiloxane with a vinyl content of 10% and a viscosity of 500cs, 60g of 2-vinylpyridine, 4.8g of neopentyl glycol diacrylate and 5g of 2,4-dichloroperoxybenzene Formyl is mixed evenly, and added to the sodium chloride powder. After the air bubbles in the sodium chloride powder are completely removed, it is sealed and reacted at 130°C for 5 hours, and then the sodium chloride powder is dissolved with water to obtain a silicone foam.

[0042] Oil-water separation experiment: Pour 50g of water and 50g of diesel into a beaker. The silicone foam is placed at the oil-water interface, and the gasoline is quickly absorbed. After taking it out, measure the size of the silicone foam. The expansion rate is 0%, and the oil absorption rate is 80%. After extrusion and washing with pH=1, the oil removal rate is 98%. The 60% deformation compressive strength of silicone foam is 1.5MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| oil absorption | aaaaa | aaaaa |

| oil absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com