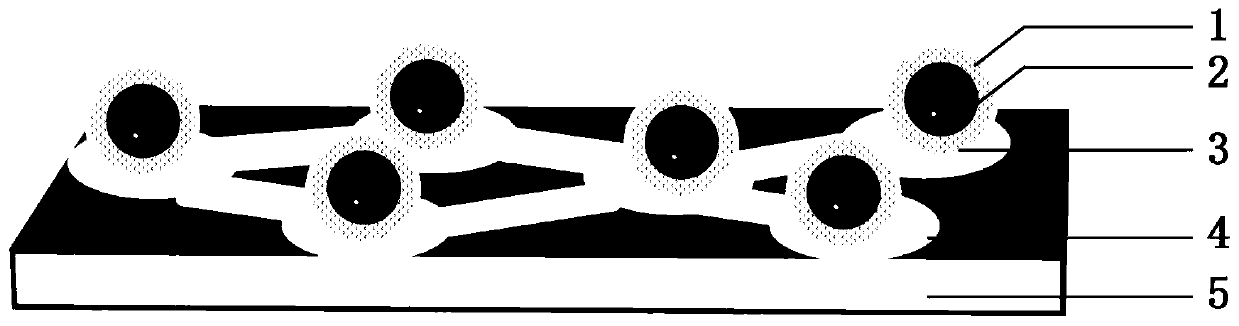

Quantum dot-nanosheet-interconnected assembled composite material and preparation method thereof

A composite material and nanosheet technology, which is applied in the field of nano-fluorescent materials, can solve the problems of inability to achieve heat dissipation, thermal quenching of quantum dots, and falling off of quantum dots, and achieves improved thermal conductivity, simple preparation method, and enhanced thermal stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

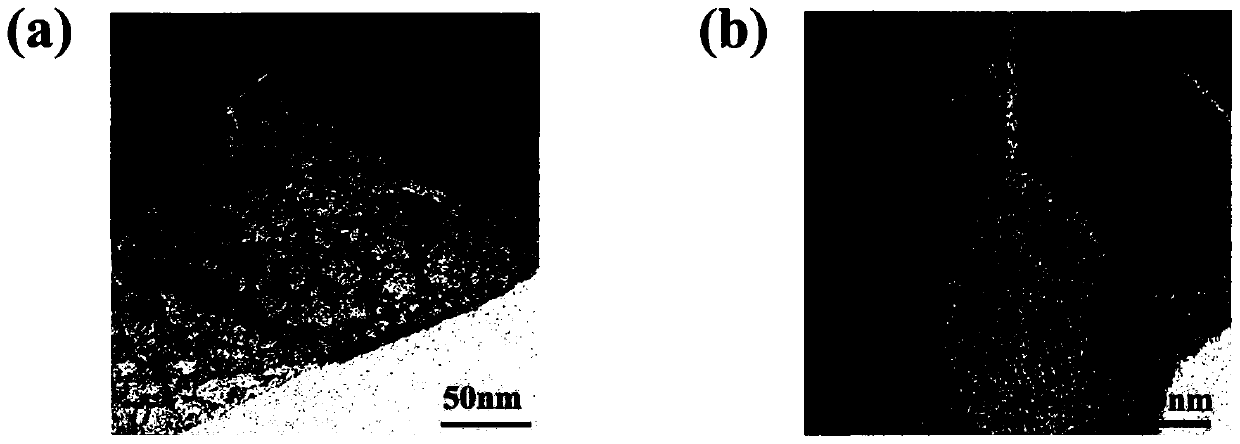

[0045] Example 1: CdSe / ZnS core-shell quantum dots and BN (boron nitride) nanosheet interconnected assembly composite (QDs-BN)

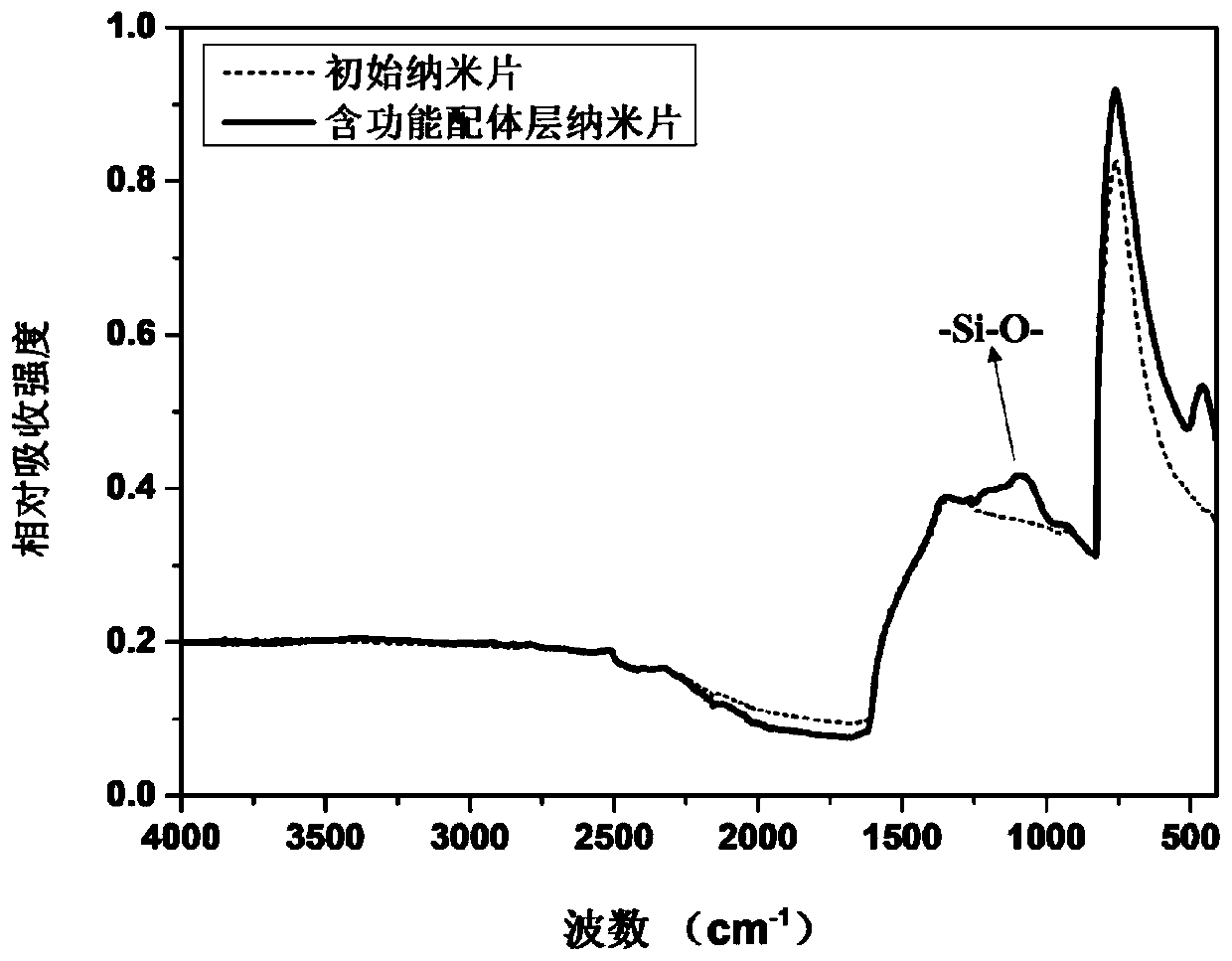

[0046] In the first step, BN nanosheets containing silicic acid ligands (second surface organic functional ligands) were prepared

[0047] In an air atmosphere at normal temperature and pressure, take 0.2 mmol of BN nanosheets and place them in 10 ml of ethanol, ultrasonicate for 15 minutes, add 2 mmol of methyl silicate, and stir at room temperature for 40 hours at a stirring speed of 300 rpm to obtain silicic acid ligands. About 10ml of BN nanosheet ethanol solution;

[0048] The second step is to prepare CdSe / ZnS core-shell quantum dots containing silicic acid ligands (the first surface organic functional ligands)

[0049] Under normal temperature and pressure air atmosphere, 0.5mmol of CdSe / ZnS core-shell quantum dots (wherein CdSe is the core material, in terms of molar mass; ZnS is the shell material) was dissolved in 5ml of xylene, and 4mmol ...

Embodiment 2

[0061] Example 2: An assembled composite material (QD@SiO 2 -BN)

[0062] In the first step, BN nanosheets containing silicic acid ligands (second surface organic functional ligands) were prepared

[0063] Except that methyl silicate is changed into ethyl silicate, other operation is the same as embodiment 1;

[0064] The second step is to prepare silica-wrapped CdSe / ZnS quantum dots containing silicic acid ligands (the first surface organic functional ligands) (where CdSe is the core material and ZnS is the shell material from the inside out)

[0065] Under normal temperature and pressure air atmosphere, 0.5mmol quantum dots are dissolved in 20ml ethanol, add 4mmol ethyl silicate, other operation is the same as embodiment 1;

[0066] The third step is to prepare the assembled composite material of silica-wrapped CdSe / ZnS core-shell quantum dots interconnected with BN (boron nitride) nanosheets

[0067] Except that the methyl silicate was changed to "ethyl silicate and 1ml ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com