Portable bacterial lysis device based on centrifugal microfluidic technology and using method thereof

A cracking device and portable technology, which is applied in the field of portable bacterial cracking devices, can solve the problems of complex microfluidic chip and device structure, low sample processing throughput, and reduced method practicability, so as to improve sample processing throughput and use mode Flexible, easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

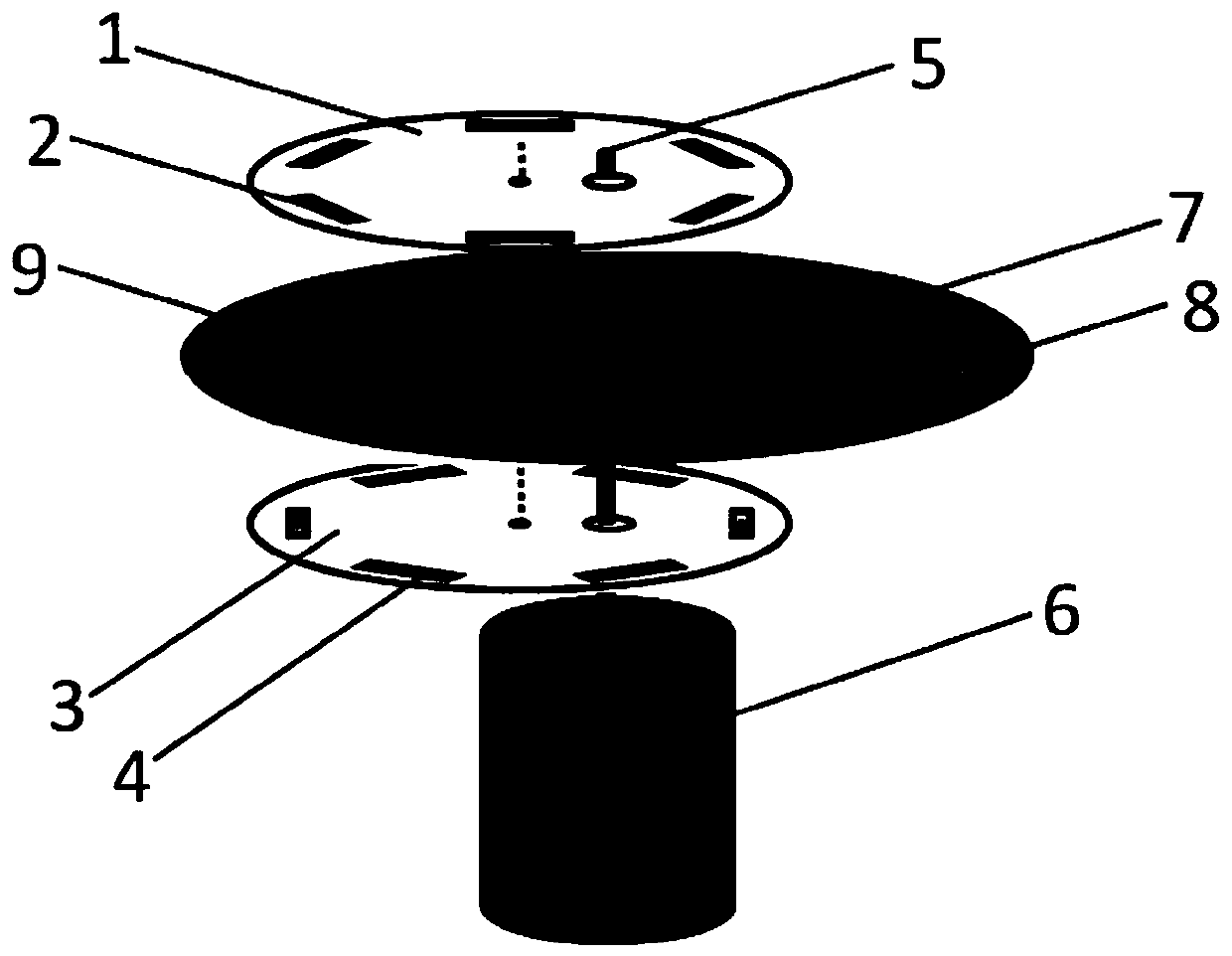

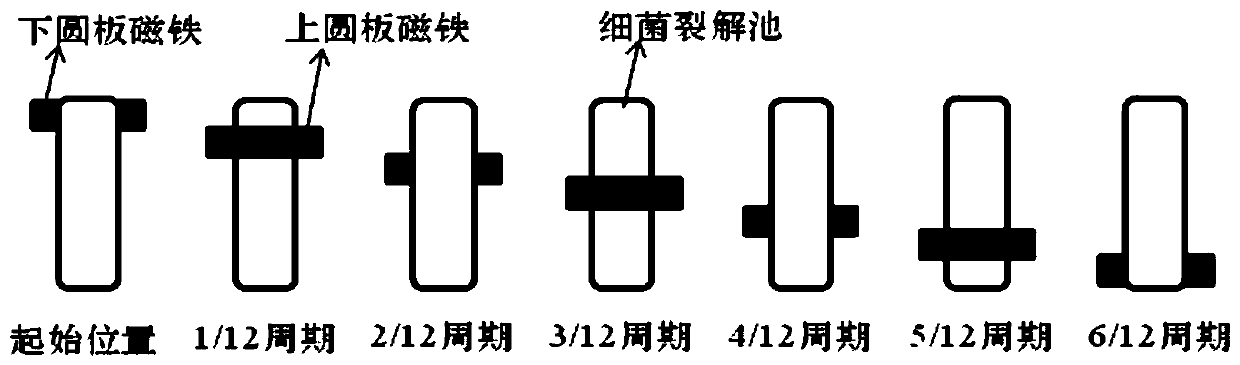

[0027] figure 1 is a schematic diagram of the structure of a portable bacterial lysing device based on centrifugal microfluidic technology, by figure 1 As shown, the device of the present invention consists of an upper disc 1, an upper disc magnet 2, a lower disc 3, a lower disc magnet 4, a rotating shaft 5, a drive motor 6, a chip tray 7, a disc microfluidic chip 8 and The bacteria lysing pool consists of 9 components. Specifically, the upper circular plate 1 and the lower circular plate 3 are arranged parallel to each other, the disk microfluidic chip 8 is located between the upper and lower circular plates and arranged parallel to the circular plates, and the rotating shaft 5 vertically runs through the two circular plates and Disc microfluidic chip 8, the rotating shaft 5 passes through the position deviated from the center of the circle on the disc and does not contact the disc, the rotating shaft 5 passes through the position of the center of the circle on the disc micr...

Embodiment 2

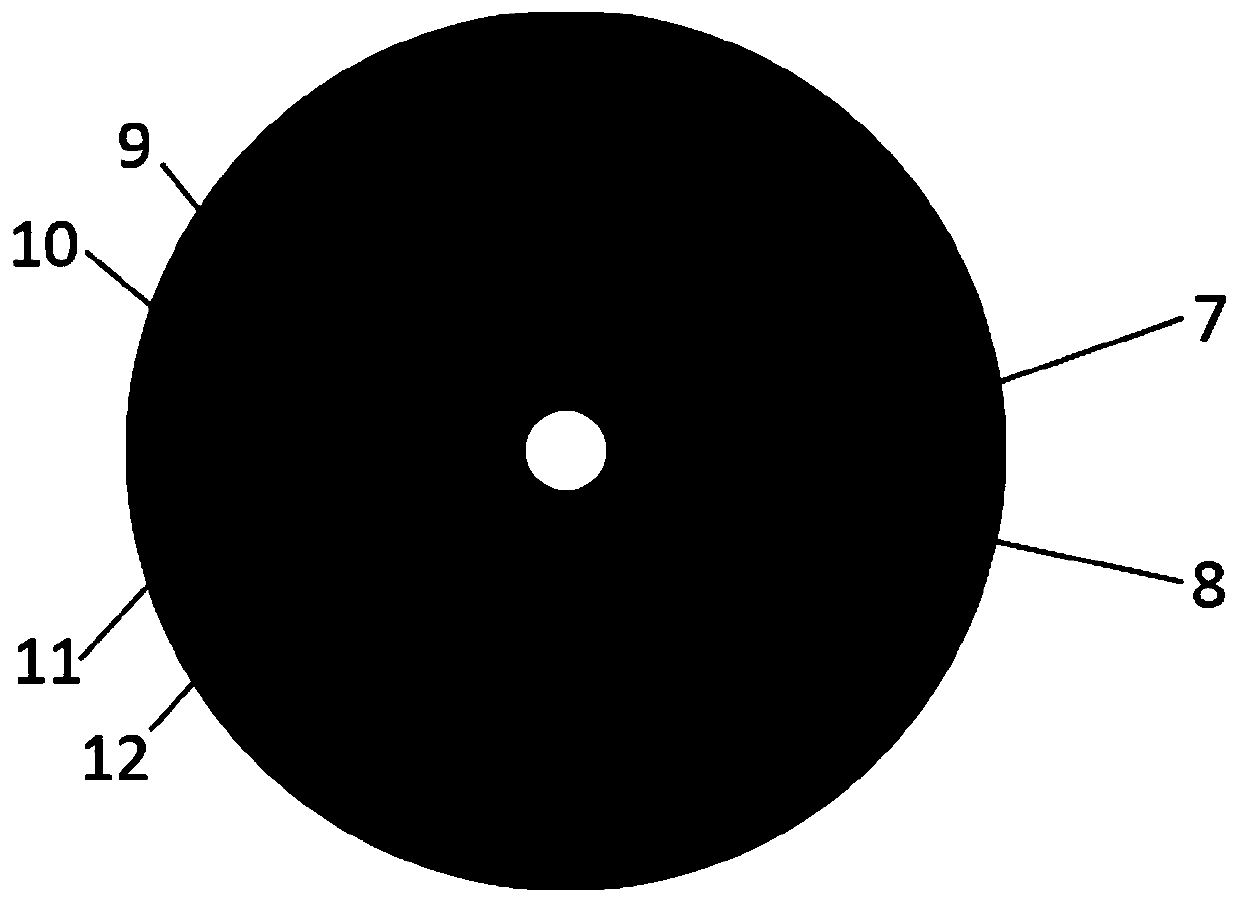

[0036] Figure 5 It is a top view of the disk microfluidic chip and the chip tray structure. The microfluidic chip includes 18 bacterial lysis pools, which can be used for efficient and rapid lysis of many bacterial samples. Among them, the outer diameter of the chip tray is 70mm, the diameter of the disc microfluidic chip is 60mm, and the size of the bacterial lysis cell is 11.8×3.5mm 2 , The diameter of the circular magnet is 2mm.

Embodiment 3

[0038] Figure 6 It is a top view of the sliced disc microfluidic chip and tray structure. A complete disc microfluidic chip is divided into 6 pieces on average, and each area includes 2 bacterial lysis pools; each piece can be used alone or in multiples. Used in combination, it can be used for high-efficiency lysis of a small number of multiple times or different numbers of bacterial samples.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com