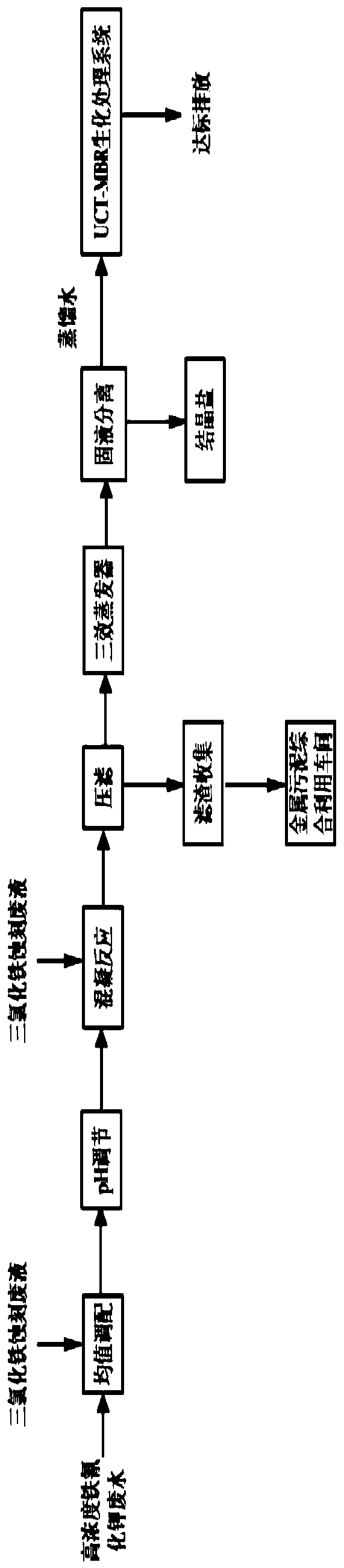

Method for cooperatively treating potassium ferricyanide-containing wastewater by utilizing ferric trichloride etching waste liquid

A ferric chloride etching and co-processing technology, applied in ceramic wastewater treatment, chemical instruments and methods, filtration treatment, etc., can solve the problem of high cost of ferric chloride etching waste liquid, high cost of potassium ferricyanide wastewater, High requirements for operation and operation, to achieve the effects of good environmental and social benefits, convenient management, and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Take 11.4t of ferricyanide-containing potassium ferricyanide wastewater from a glass product manufacturing enterprise. After analyzing the ferricyanide content in the raw material solution is about 0.512% (w%); an electronics factory ferric chloride etching waste liquid Fe 2+ Content about 21.3% (w%), Cu 2+ The content is about 0.3% (w%), and it is treated by means of blending-coagulation sedimentation-solid-liquid separation-evaporation desalination-biochemical combination process.

[0021] After coagulation and precipitation treatment, the addition ratio (w / w) of ferric chloride etching waste liquid and potassium ferricyanide wastewater is controlled at 3:8 for pH adjustment and coagulation treatment. Acid radical content is about 3.48mg / L, Cu 2+ The content is about 2.16mg / L, and the removal rate of ferricyanate is about 99.9%. Ferricyanate ions and Cu in distilled water after three-effect evaporative desalination 2+ None were detected.

Embodiment 2

[0023] Take 7.43 tons of potassium ferricyanide wastewater from a factory, and analyze the content of ferricyanide in the raw material solution to be about 0.306% (w%); adopt the average value adjustment-coagulation precipitation-solid-liquid separation-evaporation desalination-biochemical combination process.

[0024] After coagulation and precipitation treatment, the addition ratio (w / w) of ferric chloride etching waste liquid and potassium ferricyanide wastewater is controlled at 5:8 for pH adjustment and coagulation treatment. Acid radical content about 0.15mg / L, Cu 2+ The content is about 15.3mg / L, and the removal rate of ferricyanate is about 99.9%. Ferricyanate ions and Cu in distilled water after three-effect evaporative desalination 2+ None were detected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com