Ferronickel residue hollow ceramic plate and preparation method thereof

A hollow ceramic plate and nickel-iron slag technology, which is applied to ceramic products, clay products, and other household appliances, can solve the problems of unsatisfactory appearance quality of ceramic plates, inappropriate preparation of hollow ceramic plates, and difficulties in the preparation of hollow ceramic plates, so as to improve plasticity, The effect of increased bonding and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

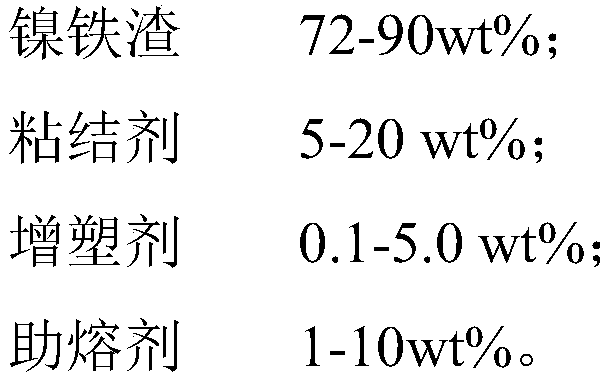

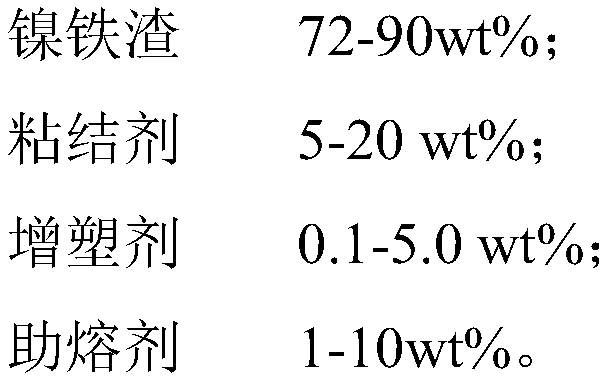

[0028] The raw materials for preparing the nickel-iron slag hollow ceramic plate in this embodiment include: 72kg of nickel-iron slag, 10kg of perlite ore, 10kg of black mud, 0.1kg of methylcellulose, and 7.9kg of albite (particles≤200 mesh).

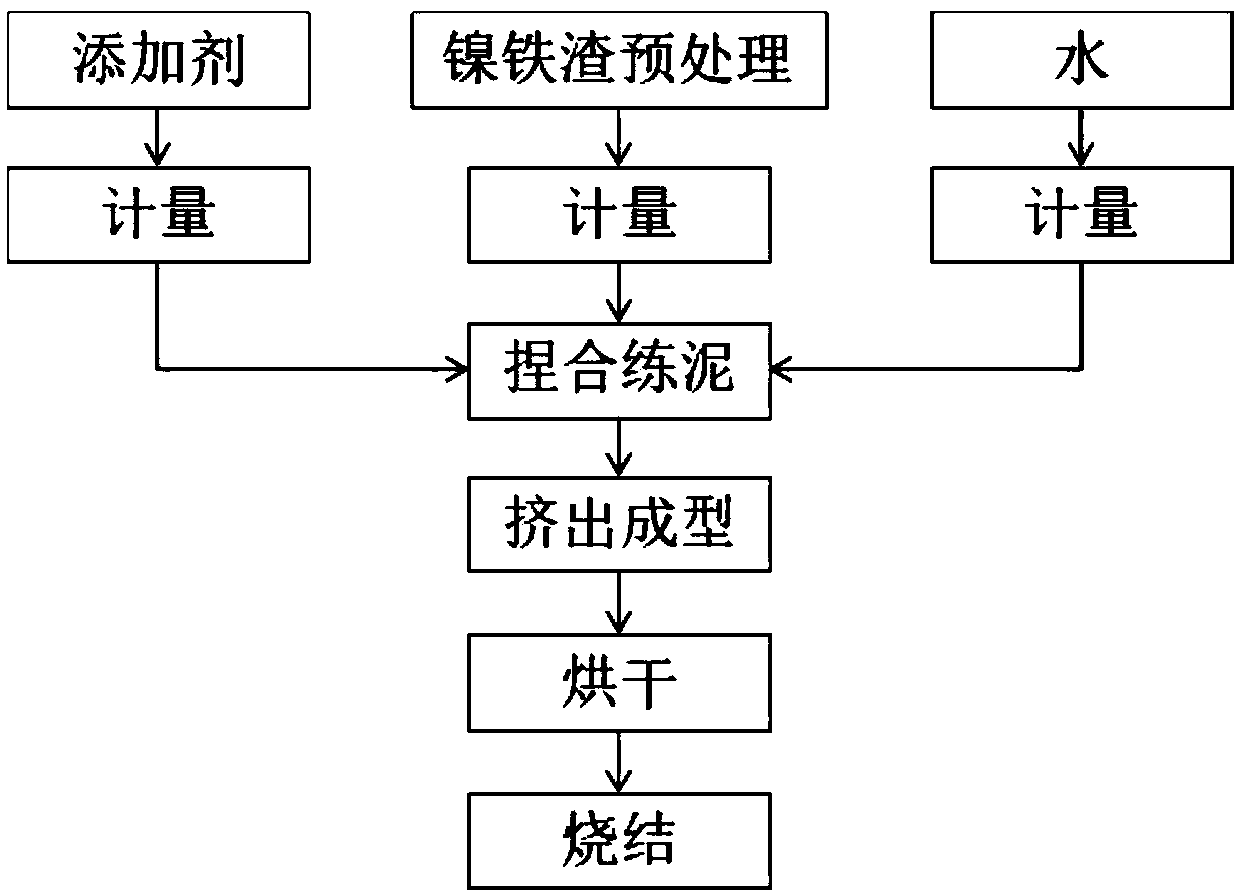

[0029] like figure 1 The shown process flow diagram, the preparation method of the nickel-iron slag hollow ceramic plate in the present embodiment, comprises the following steps:

[0030] (1) get the nickel-iron slag and pass it through the ball mill ball mill, then sieve, select the particle below 100 meshes, standby;

[0031] (2) get selected amount of described nickel-iron slag, binder, plasticizer, fluxing agent and mix, respectively by kneader to mix 10min in middle, add the water that accounts for 28wt% of described raw material total amount, by refining mud The machine repeats the mud practice 10 times to obtain the mixture, which is used for standby;

[0032] (3) extruding the obtained mixture through a ceramic plate shaft ext...

Embodiment 2

[0035] The raw materials for the preparation of the nickel-iron slag hollow ceramic plate in this embodiment include: 90kg of nickel-iron slag, 3kg of calcium bentonite, 2kg of raw kaolin, 1kg of sodium lignosulfonate, 0.5kg of methyl cellulose, hectorite (particles≤200 head) 3.5kg.

[0036] like figure 1 The shown process flow diagram, the preparation method of the nickel-iron slag hollow ceramic plate in the present embodiment, comprises the following steps:

[0037] (1) get the nickel-iron slag and pass it through the ball mill ball mill, then sieve, select the particle below 100 meshes, standby;

[0038] (2) get selected amount of described nickel-iron slag, binder, plasticizer, flux and mix, respectively by kneader to mix 3min in middle, add the water that accounts for the total amount of described raw material 14wt%, by refining mud The machine repeats the mud for 15 times to obtain the mixture, which is ready for use;

[0039] (3) extruding the obtained mixture throu...

Embodiment 3

[0042] The raw materials for the preparation of the nickel-iron slag hollow ceramic plate in this embodiment include: 84kg of nickel-iron slag, 5kg of calcium bentonite, 3kg of perlite ore, 1.5kg of calcium lignosulfonate, 2kg of albite (particles≤200 mesh), 2kg of potassium Feldspar (particles≤200 mesh) 4.5g.

[0043] like figure 1 The shown process flow diagram, the preparation method of the nickel-iron slag hollow ceramic plate in the present embodiment, comprises the following steps:

[0044] (1) get the nickel-iron slag and pass it through the ball mill ball mill, then sieve, select the particle below 100 meshes, standby;

[0045] (2) get selected amount of described nickel-iron slag, binder, plasticizer, fluxing agent and mix, respectively by kneader to mix 6min in middle, add the water that accounts for the total amount of described raw material 18wt%, by refining mud The machine repeats the mud practice 5 times to obtain the mixture, which is used for standby;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com