Cement-based floor polymer waterproof coating, preparation method and equipment

A technology of waterproof coating and base floor, which is applied in the direction of chemical instruments and methods, coatings, mixers, etc. It can solve the problems that the heating temperature cannot be controlled accurately, the finished waterproof coating is not effective, and the user's production cost is increased. , to achieve the effects of not easy to mildew, strong acid and alkali resistance, and increased elastic adhesion ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

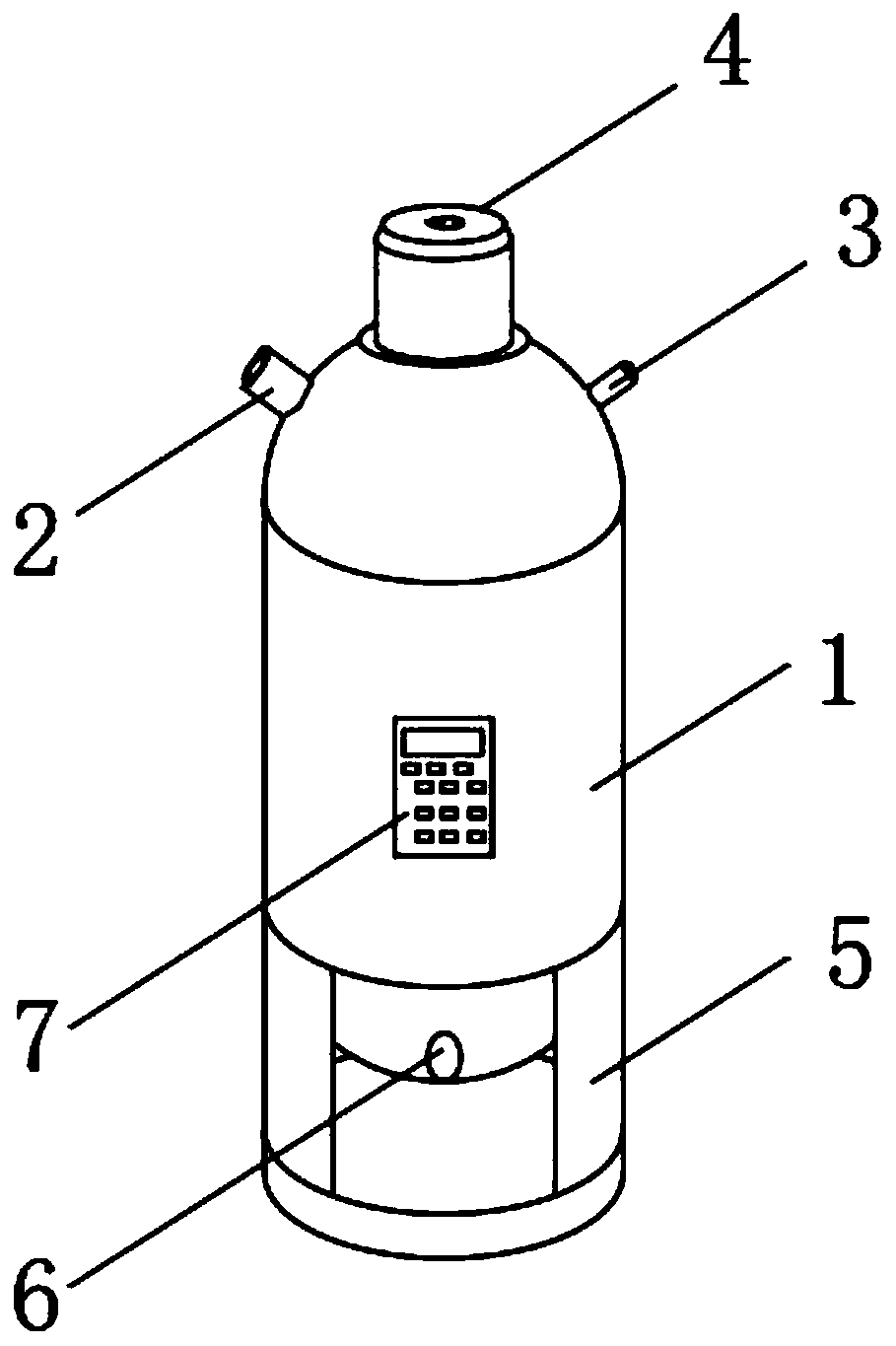

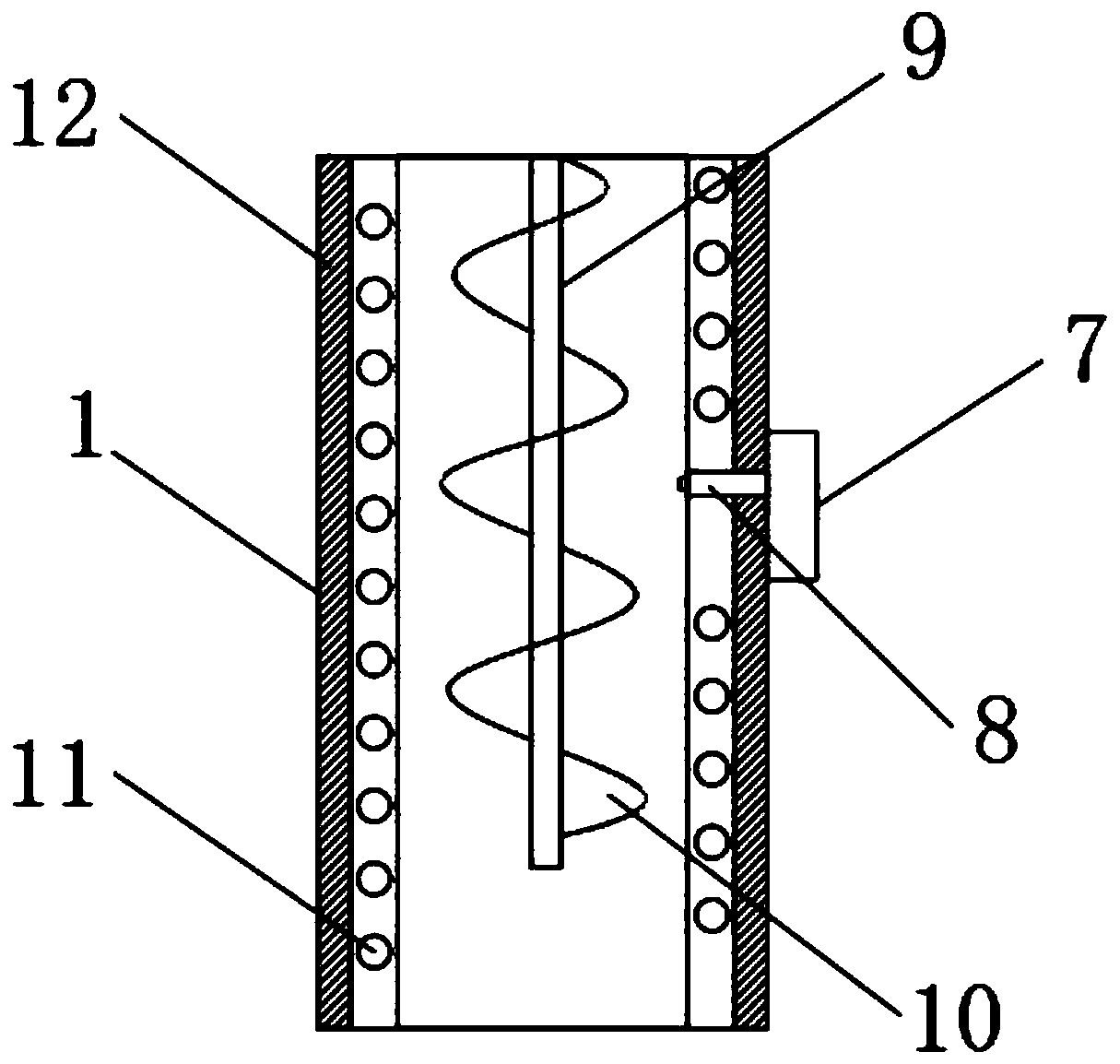

[0029] see Figure 1 to Figure 2 , the cement-based floor polymer waterproof coating provided by the present embodiment is made of the following parts by weight: 68-73 parts of water-based acrylic emulsion, 1-2 parts of ethyl naphthol, 2-3 parts of ditetradecyl alcohol ester , 0.1-0.2 parts of lithium chromate, 2-3 parts of polyether glycol, 0.6-1 part of polyacrylamide, 0.6-1 part of 2,6-di-tert-butyl-p-cresol, 2-3 parts of oxidized polyethylene wax , 1-2 parts of potassium dodecylbenzenesulfonate, 0.6-1 part of N-methylpyrrolidone, 0.3-0.5 parts of ricinoleic acid, 6-8.5 parts of expanded perlite, 6-7 parts of sericite powder, film-forming 6-8 parts of additives, 10-16 parts of deionized water, 1-3 parts of rosin modified phenolic resin, 2-3 parts of anti-settling agent, 1.1 parts of leveling agent, and 0.85 parts of defoaming agent.

[0030] Specifically, in this embodiment,

[0031] Cement-based floor polymer waterproof coating, which is made of the following components ...

Embodiment 2

[0045] The cement-based floor polymer waterproof coating, preparation method and equipment provided in this embodiment are basically the same as in Example 1, except that:

[0046] The cement-based floor polymer waterproof coating provided by the present embodiment is made of the following parts by weight: 70 parts of aqueous acrylic emulsion, 1.5 parts of ethyl naphthol, 2.5 parts of ditetradecyl alcohol ester, 0.15 parts of lithium chromate, 2.5 parts of polyether glycol, 0.8 parts of polyacrylamide, 0.8 parts of 2,6-di-tert-butyl-p-cresol, 2.5 parts of oxidized polyethylene wax, 1.5 parts of potassium dodecylbenzenesulfonate, N-methyl 0.8 parts of pyrrolidone, 0.4 parts of ricinoleic acid, 7.5 parts of expanded perlite, 6.5 parts of sericite powder, 7 parts of film-forming aids, 14 parts of deionized water, 2 parts of rosin modified phenolic resin, 2.5 parts of anti-settling agent, fluid 1.1 parts of leveling agent, 0.85 parts of defoamer.

[0047] The film-forming aid is ...

Embodiment 3

[0049] The cement-based floor polymer waterproof coating, preparation method and equipment provided in this embodiment are all basically the same as those in Examples 1 and 2, except that:

[0050] The cement-based floor polymer waterproof coating provided by the present embodiment is made of the following parts by weight: 73 parts of aqueous acrylic emulsion, 2 parts of ethyl naphthol, 3 parts of ditetradecyl alcohol ester, 0.2 part of lithium chromate, 3 parts of polyether glycol, 1 part of polyacrylamide, 1 part of 2,6-di-tert-butyl-p-cresol, 3 parts of oxidized polyethylene wax, 2 parts of potassium dodecylbenzenesulfonate, N-methyl 1 part of pyrrolidone, 0.5 part of ricinoleic acid, 8.5 parts of expanded perlite, 7 parts of sericite powder, 8 parts of film-forming aid, 16 parts of deionized water, 3 parts of rosin modified phenolic resin, 3 parts of anti-precipitation agent, fluid 1.1 parts of leveling agent, 0.85 parts of defoamer.

[0051] The film-forming aid is made ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com