A kind of long-acting microemulsion cutting fluid for metal processing and preparation method thereof

A technology for metal processing and cutting fluid, applied in the field of long-acting micro-emulsion cutting fluid for metal processing and its preparation, can solve the problems of difficulty in effectively guaranteeing the use effect, large temperature fluctuations, poor stability of cutting fluid, etc., and achieves extended storage. and service life, improved distribution coefficient, stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

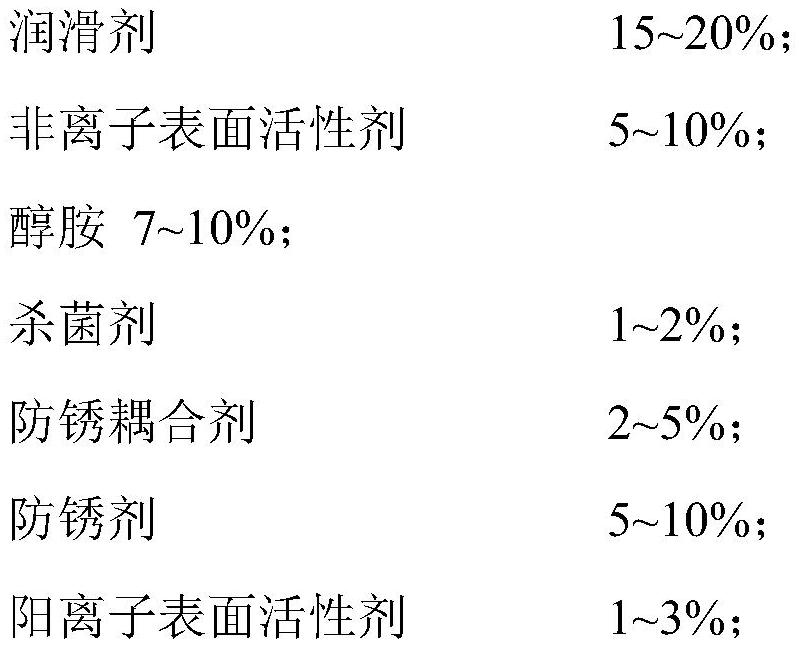

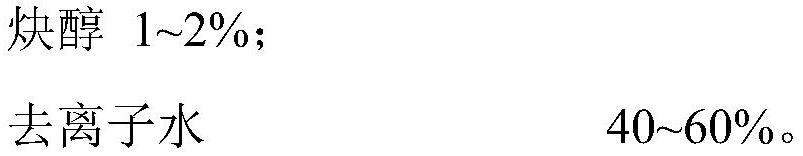

[0036] A preparation method of a long-acting micro-emulsion cutting fluid for metal processing of the present invention comprises the following steps:

[0037] Step 1: Mix 15-20% Priolube 3955, 2-3% RT45LT, 2-5% RT64LT and 1-2% EL20, and stir well;

[0038] Step 2: Mix 5~7% DGA, 2~3% AMP-95, 2~5% Guerbet acid, 5~10% L190 PLUS and 40~60% deionized water at 40~60℃ , get phase two;

[0039] Step 3: Put the phase 1 obtained in step 1 into the reaction kettle, keep the temperature between 30 and 40 ° C, start stirring, and slowly put 1-2% FS-640, 0.1-0.3% ROCIMA342, 1-3% BUSAN77 into it in turn. , 0.9-1.9% BIT20, stir for 50-70min, and then slowly inject the phase 2 obtained in step 2 into the above system, and continue stirring for 3-5h to obtain cutting fluid.

[0040] In the prior art, in order to make the metal working fluid spread evenly on the metal surface and thus ensure a good processing effect, a surfactant that can reduce the surface tension is usually added to the cut...

Embodiment 1

[0046] (1) Mix 20% Priolube 3955, 2% RT45LT, 3% RT64LT and 1% EL20, and stir well;

[0047] (2) Mix 6% DGA, 3% AMP-95, 4% Guerbet acid, 6% L190 PLUS and 51% deionized water at 50°C to obtain phase two;

[0048] (3) put the obtained phase one in (1) into the reaction kettle, keep the temperature between 30 ℃, start stirring, and slowly put 1.8% FS-640, 0.2% ROCIMA342, 1% BUSAN77, 1% BIT20 into it successively, After stirring for 60 min, slowly inject the phase two obtained in (2) into the above system, and continue stirring for 4 h to obtain the cutting fluid.

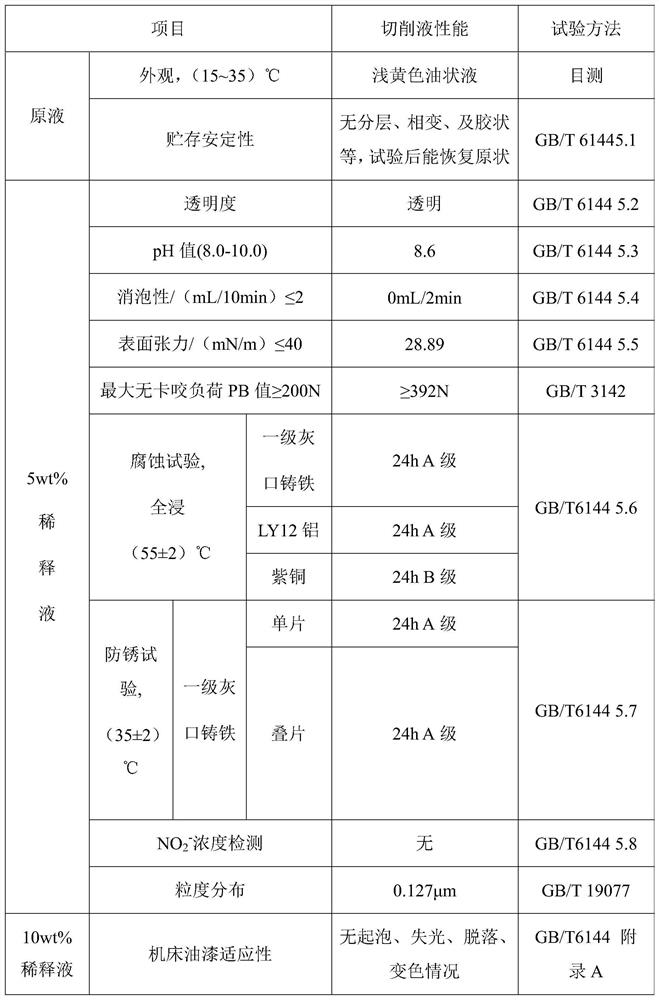

[0049] The above obtained cutting fluid stock solution is diluted to obtain a 5wt% dilution solution and a 10wt% dilution solution. The stock solution and the dilution solution are respectively tested for appearance, stability, anti-corrosion, anti-rust performance, particle size and other properties. Test method and result as figure 1 shown. from figure 1 It can be seen that the stock solution of the cutting fluid ...

Embodiment 2

[0051] (1) Mix 15% Priolube 3955, 2% RT45LT, 2% RT64LT and 2% EL20, and stir well;

[0052] (2) Mix 5% DGA, 2% AMP-95, 2% Guerbet acid, 5% L190 PLUS and 60% deionized water at 40°C to obtain phase two;

[0053] (3) put the obtained phase one in (1) into the reaction kettle, keep the temperature between 35 ℃, start stirring, and slowly put 2% FS-640, 0.1% ROCIMA342, 1% BUSAN77, 1.9% BIT20 into it successively, After stirring for 65min, slowly inject the phase two obtained in (2) into the above system, and continue stirring for 3h to obtain the cutting fluid.

[0054] To above-mentioned gained cutting fluid stoste and its dilution, obtain 5wt% diluent and 10wt% diluent, respectively carry out appearance, stability, anti-corrosion, anti-rust performance, particle size and other properties to stoste and diluent to test (test method Same as Example 1), test results are basically the same as Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com