Solid dielectric for filter and its surface metallization process and dielectric filter

A solid medium, surface metal technology, applied in the field of communication, can solve the problems of reducing device performance, cracking of metal film layer, easy to be worn out, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

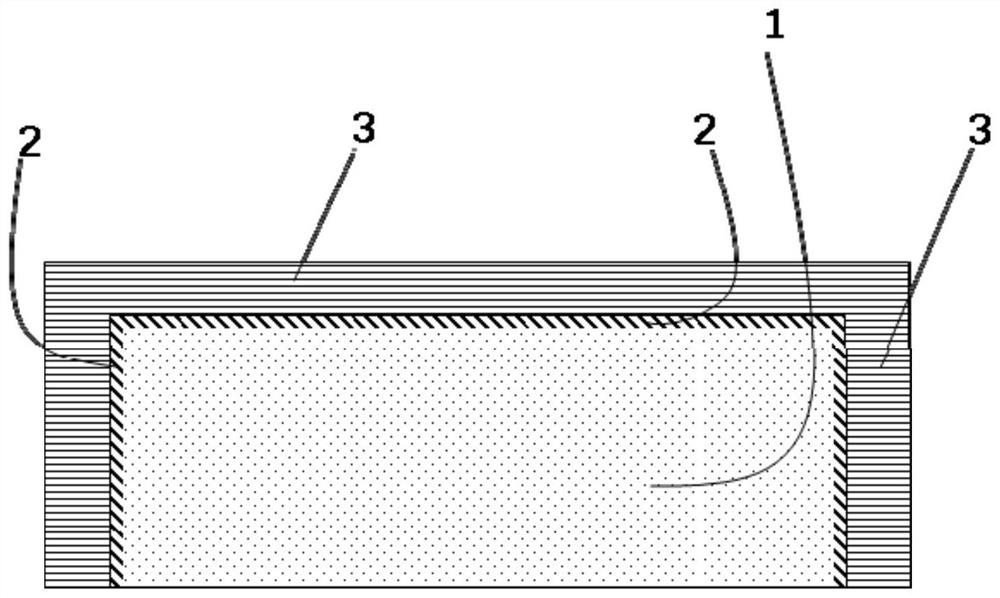

[0042] like figure 1 As shown, in Embodiment 1 of the present invention, the solid medium used for the filter includes a solid medium body 1, and also includes a conductor structure arranged on the surface of the solid medium body, and the conductor structure includes at least one for signal transmission. The first conductive metal layer 2 and the second conductive metal layer 3 for the surface soldering layer; the first conductive metal layer 2 is located on the surface of the solid dielectric body 1; the second conductive metal layer 3 is located on the first conductive metal layer 2 surface; the first conductive metal layer 2 and the second conductive metal layer 3 are conductive layers of different metal materials.

[0043] The surface metallization process of the above-mentioned solid medium, including

[0044] Solid medium body surface treatment step: Since the surface of the sintered solid medium will form a dense polished surface, which is not conducive to the combina...

Embodiment 2

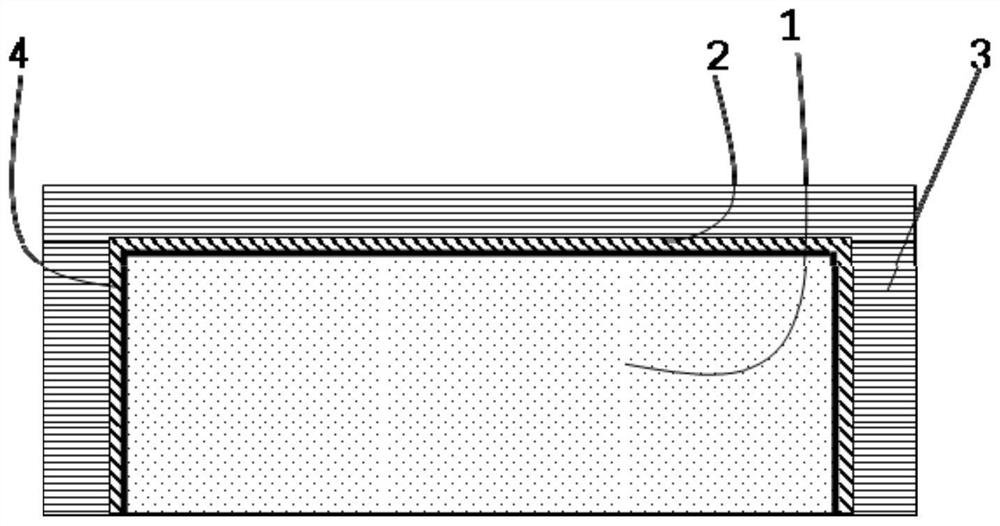

[0058] In Embodiment 2 of the present invention, on the basis of Embodiment 1, further, the conductor structure further includes a third conductor metal layer 4, and the third conductor metal layer 4 is located between the solid dielectric body 1 and the first Between the conductive metal layer 2. In the present invention, the third conductive metal layer is firstly covered on the surface of the solid medium as a transition layer, and then the surface is sintered by screen printing sintering method, electrosilver method, LTCC method, vacuum evaporation method and magnetron sputtering method. A method described herein forms a first conductive metal layer. The purpose of the third conductive metal layer is to enhance the adhesion between the first conductive metal layer for signal transmission and the solid medium. The third conductor metal layer is used as a transition layer. The transition layer connects the solid medium and the first conductor metal layer. The metal material...

Embodiment 3

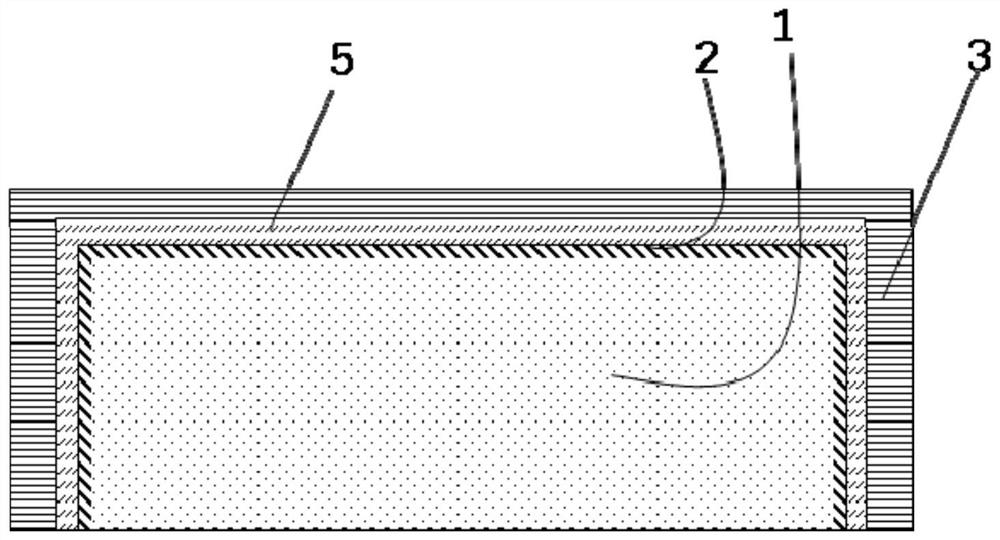

[0069] In Embodiment 3 of the present invention, on the basis of Embodiment 1 above, further, the conductor structure further includes a fourth conductor metal layer 5, and the fourth conductor metal layer 5 is located on the first conductor metal layer 2 and the second conductive metal layer 3.

[0070] Surface metallization process of solid media, including

[0071] Solid medium body surface treatment step: Since the surface of the sintered solid medium will form a dense polished surface, which is not conducive to the combination of the solid medium and the metal layer, it is necessary to roughen the surface of the sintered solid medium in this step Grinding treatment, roughening treatment can adopt the sandpaper of mesh number 150-500 to polish; Then the solid medium after surface roughening is cleaned, removes surface impurity and chemical substance, can take directly to use chemical reagent in the present invention (such as ethanol, deionized water) for rinsing, and etha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com