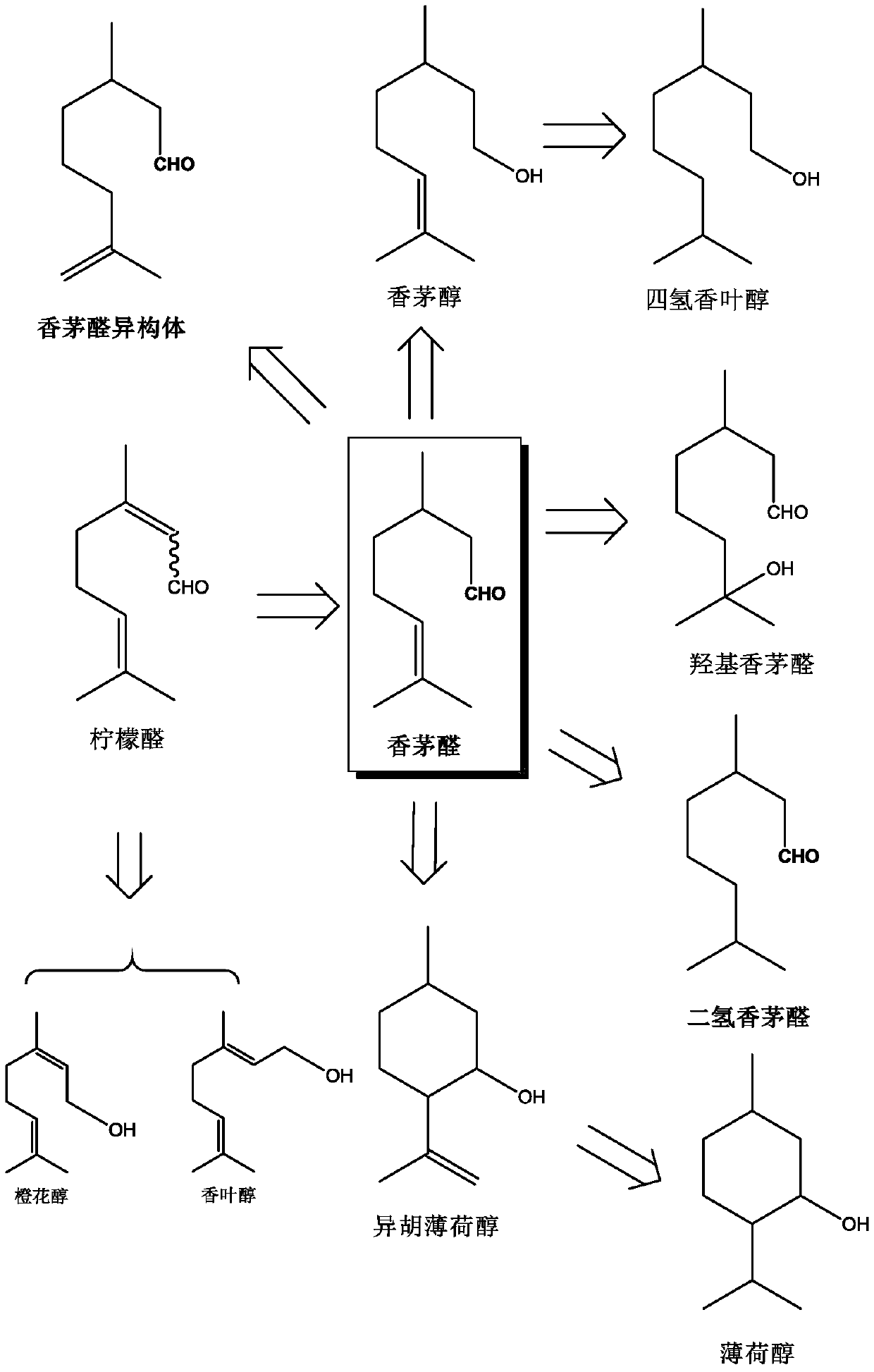

Hydrogenation catalyst and preparation method thereof, and method for preparing citronellal by citral hydrogenation

A hydrogenation catalyst and citral technology, applied in the field of hydrogenation, can solve the problems of cumbersome treatment, inconsistent with green chemistry, and many wastes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

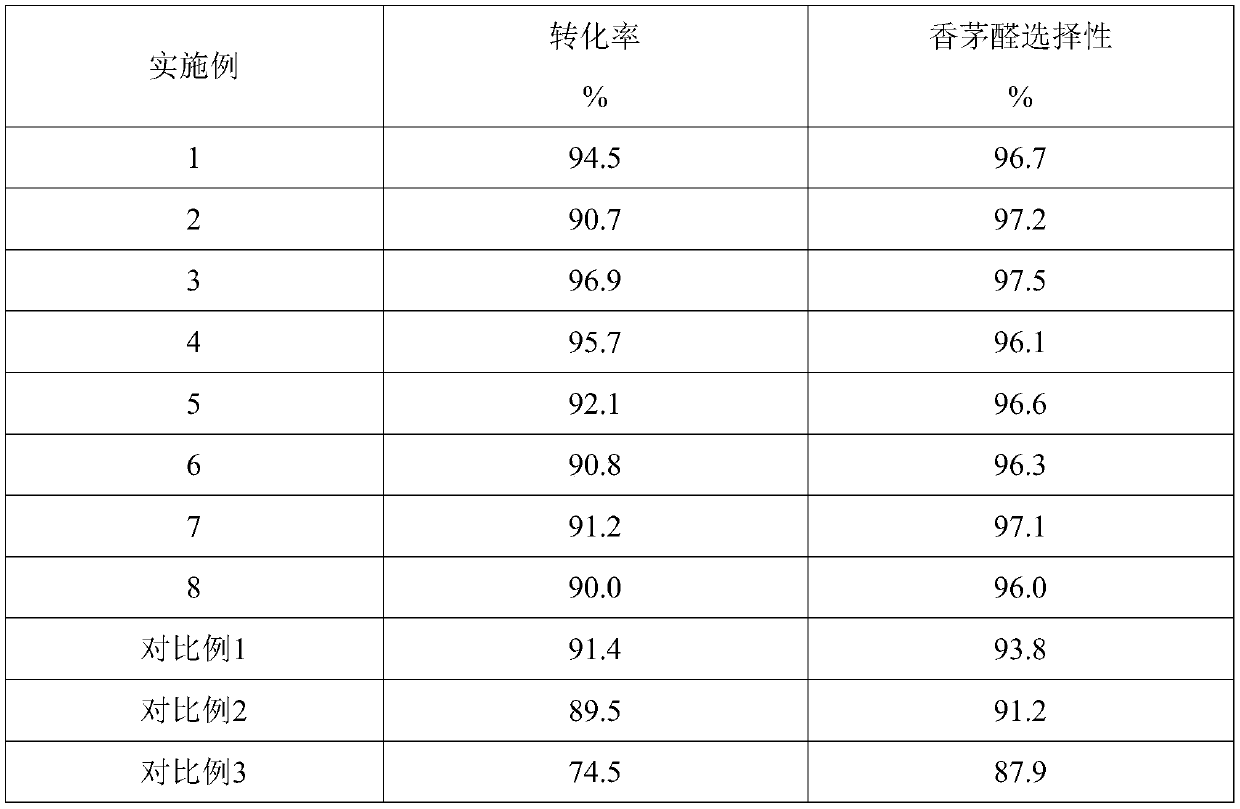

Examples

Embodiment 1

[0048] L 3 preparation

[0049] Put 100g of rare earth element La in a reaction furnace for hydrogenation reaction, the reaction temperature is 250°C, the reaction pressure is 2Mpa (A), and the reaction time is 3h to obtain the rare earth hydride LaH 3 ;

[0050] Complex carrier preparation

[0051] Take 50g LaH 3 and 5g Fe 3 o 4 Put it in a mechanical ball mill, and carry out composite treatment at 50°C for 5 hours under 1bar (G) hydrogen atmosphere to obtain a composite carrier with a particle size of 0.05mm;

[0052] target catalyst preparation

[0053] 1) Dissolve 2.01g dichlorodiammine palladium in 10g water, fully dissolve and impregnate with 55g composite carrier to obtain a catalyst precursor;

[0054] 2) Reducing the catalyst precursor at 120°C for 4 hours in a hydrogen atmosphere to obtain a hydrogenation catalyst 2wt%Pd / 10wt%Fe 3 o 4 -LaH 3 .

[0055] Response Performance Evaluation

[0056] Add 2wt%Pd / 10wt%Fe successively in a 500ml hydrogenation reaction...

Embodiment 2

[0058] L 3 preparation

[0059] Put 100g of rare earth element La in a reaction furnace for hydrogenation reaction, the reaction temperature is 320°C, the reaction pressure is 4Mpa (A), and the reaction time is 7h to obtain the rare earth hydride LaH 3 ;

[0060] Complex carrier preparation

[0061] Take 50g LaH 3 and 7.5g Fe 3 o 4 Put it in a mechanical ball mill, and perform composite treatment at 60°C for 8 hours under 3bar (G) hydrogen atmosphere to obtain a composite carrier with a particle size of 0.06mm;

[0062] target catalyst preparation

[0063] 1) 3.01g dichlorodiammine palladium was dissolved in 10g water, fully dissolved and impregnated with 57.5g composite carrier to obtain a catalyst precursor;

[0064] 2) The catalyst precursor was reduced at 140°C for 8 hours in a hydrogen atmosphere to obtain a hydrogenation catalyst 3wt%Pd / 15wt%Fe 3 o 4 -LaH 3 .

[0065] Response Performance Evaluation

[0066] Add 3wt%Pd / 15wt%Fe successively in 500ml hydrogenat...

Embodiment 3

[0068] L 3 preparation

[0069] Put 100g of rare earth element La in a reaction furnace for hydrogenation reaction, the reaction temperature is 380°C, the reaction pressure is 6Mpa (A), and the reaction time is 12h to obtain the rare earth hydride LaH 3 ;

[0070] Complex carrier preparation

[0071] Take 50g LaH 3 and 10g Fe 3 o 4 Put it in a mechanical ball mill, and perform composite treatment at 70°C for 13 hours under a hydrogen atmosphere of 6bar (G) to obtain a composite carrier with a particle size of 0.07mm;

[0072] target catalyst preparation

[0073] 1) Dissolve 4.01g dichlorodiammine palladium in 10g water, fully dissolve and impregnate with 60g composite carrier to obtain a catalyst precursor;

[0074] 2) Reducing the catalyst precursor at 100°C for 4 hours in a hydrogen atmosphere to obtain a hydrogenation catalyst 4wt%Pd / 20wt%Fe 3 o 4 -LaH 3 .

[0075] Response Performance Evaluation

[0076] Add 4wt%Pd / 20wt%Fe successively in a 500ml hydrogenation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com