Hollow glass bead composite phthalonitrile resin rigid foam and preparation method thereof

A technology of phthalonitrile resin and hollow glass microspheres, which is applied in the field of composite materials, can solve the problems of slow curing rate of aromatic amine curing agent, etc., and achieve the effect of good flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] The formula of a kind of hollow glass microsphere composite phthalonitrile resin rigid foam provided by the present embodiment is as follows:

[0057] 1,2,3,6-tetrahydrophthalic anhydride type capped imide monomer 268g Resorcinol type bisphthalonitrile monomer 484g Hollow glass microspheres (GS20, true density 0.18~0.22g / cm 3 )

188g Silane coupling agent KH550 23g Ethanol (recyclable for continued use) 1533g

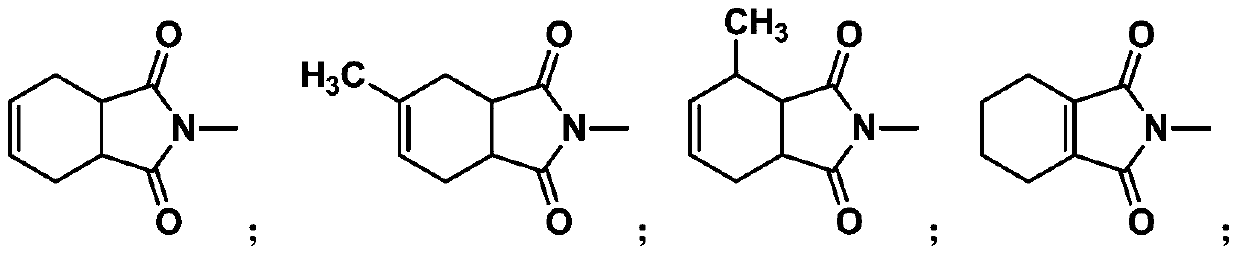

[0058] Wherein, the structural formula of 1,2,3,6-tetrahydrophthalic anhydride type capped imide monomer is as follows:

[0059]

[0060] The structural formula of the resorcinol type diphthalonitrile monomer is as follows:

[0061]

[0062] The preparation method of above-mentioned rigid foam is:

[0063] S1) The 1,2,3,6-tetrahydrophthalic anhydride-type end-capped imide monomer powder and the resorcinol-type diphthalonitrile monomer powder were respectively pulverized, ground, sampled, and blended uniformly, and t...

Embodiment 2

[0070] The formula of a kind of hollow glass microsphere composite phthalonitrile resin rigid foam provided by the present embodiment is as follows:

[0071] 1,2,3,6-tetrahydrophthalic anhydride type capped imide monomer 268g Resorcinol type bisphthalonitrile monomer 484g Hollow glass microspheres (GS15, true density 0.13~0.17g / cm 3 )

188g Silane coupling agent KH550 23g Ethanol (recyclable for continued use) 1533g

[0072] The preparation method of the above-mentioned rigid foam is basically the same as that of Example 1, so it will not be repeated one by one.

[0073] The hollow glass microsphere composite imide phthalonitrile rigid foam prepared in this example is black in appearance, dense, and has a density of 0.35g / cm 3 , the thermal conductivity is 0.06W / (m K), the limiting oxygen index is 38%, there is no droplet, the flame retardant performance is V-0 level, there is no glass transition temperature observed within 400°C, and t...

Embodiment 3

[0075] The formula of a kind of hollow glass microsphere composite phthalonitrile resin rigid foam provided by the present embodiment is as follows:

[0076] 1,2,3,6-tetrahydrophthalic anhydride type capped imide monomer 105g Hexahydrophthalic anhydride type blocked siloxane imide monomer 117g Phloroglucinol type diphthalonitrile monomer 530g Hexaphenoxycyclotriphosphazene 37.6g Hollow glass microspheres (GS20, true density 0.18~0.22g / cm 3 ))

188g Silane coupling agent KH550 23g Ethanol (recyclable for continued use) 1533g

[0077] Wherein, the structural formula of 1,2,3,6-tetrahydrophthalic anhydride type capped imide monomer is as follows:

[0078]

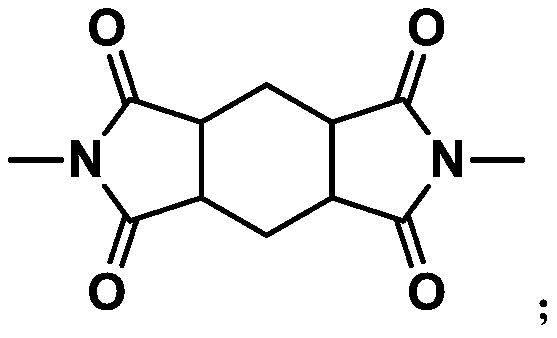

[0079] The structural formula of the hexahydrophthalic anhydride type end-capped siloxane imide monomer is as follows:

[0080]

[0081] The structural formula of the phloroglucinol type bis-phthalonitrile monomer is as follows:

[0082]

[0083] The structural for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap