UiO-66(NH2)-silver sulfide composite material and preparation process thereof

A composite material and preparation technology, applied in the field of composite materials, can solve the problems of chemical stability, detection limit and poor linear range, etc., and achieve the effect of improving chemical stability, good volatility, and improving purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: synthetic UiO-66 (NH 2 )-The preparation technology of silver sulfide composite material, concrete steps are,

[0024] S1: Synthesis of UiO-66(NH 2 ), specifically, a. Using a solvothermal reaction method, ultrasonically dissolve zirconium tetrachloride and 2-aminoterephthalic acid in a DMF solution, transfer to a reaction kettle, and react at 120° C. for 24 hours; b. The pale yellow product obtained after the reaction in the reactor in a was centrifuged, washed 3 times with washing solvent, dried in vacuum at 80°C, and left to stand to obtain UiO-66 (NH 2 ) solid powder.

[0025] S2: A layer of UiO-66(NH 2 ), specifically, a, cutting the FTO glass into flakes, ultrasonic cleaning in absolute ethanol and deionized water for 3 minutes successively, b, drying the flake FTO glass after cleaning in step a with nitrogen, taking 2.5 mg mL -1 UiO-66 (NH 2 ) evenly drop on the surface of FTO glass, and let it dry naturally at room temperature.

[0026] S3: ...

Embodiment 2

[0027] Embodiment 2: UiO-66 (NH 2 )-silver sulfide composite

[0028] Using the technique in Example 1, UiO-66(NH 2 )-silver sulfide composite.

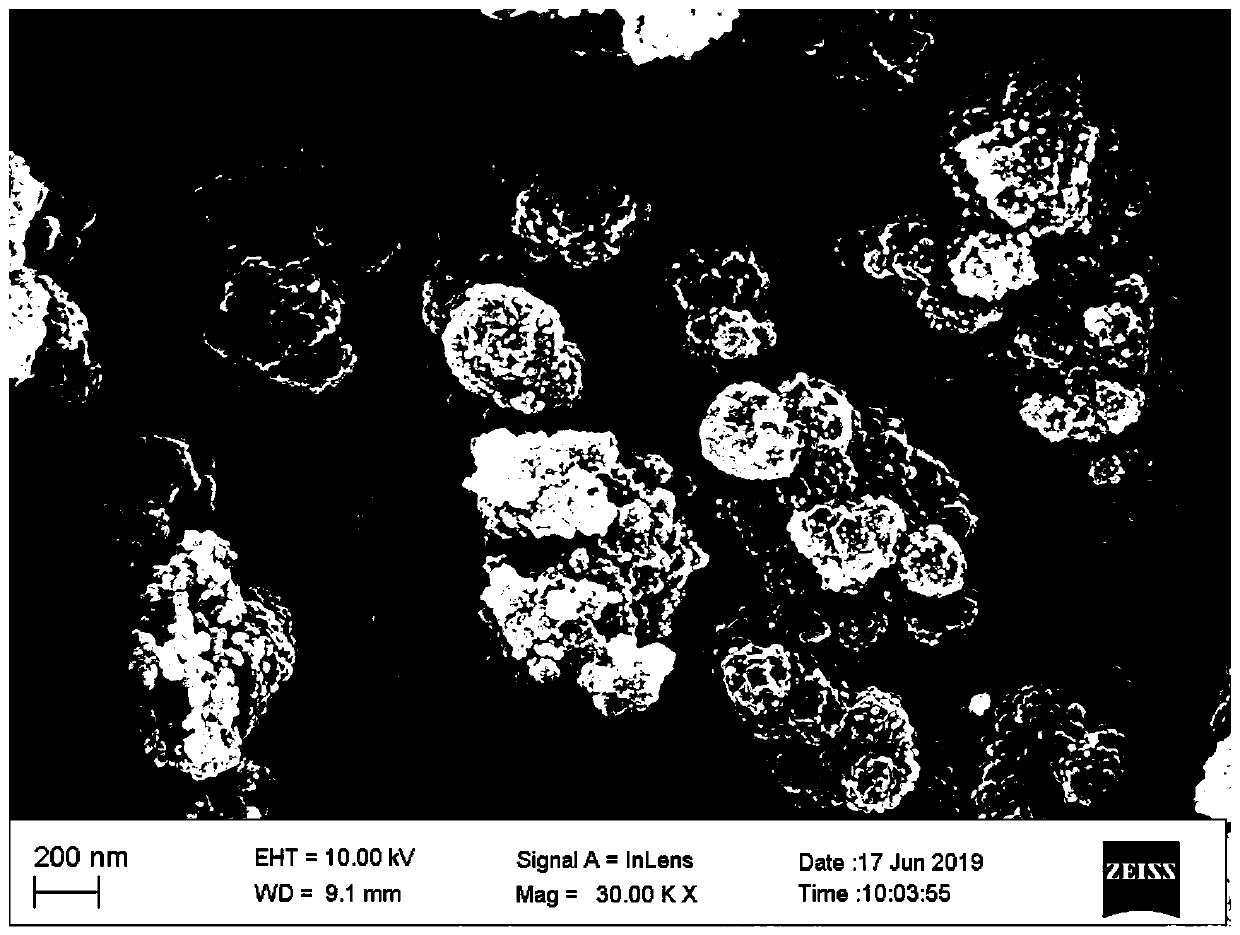

[0029]For the prepared UiO-66(NH 2 )-Silver sulfide test its SEM image, the results are as follows figure 1 shown. From figure 1 It can be seen that the synthesized UiO-66(NH 2 )-silver sulfide has a narrow band gap, and the semiconductor material that can utilize the narrow band gap also has good absorbance in the visible light region, so as to avoid the inactivation of biomolecules caused by ultraviolet light.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com