Anticorrosive and antifouling integrated paint for coating repair and preparation method thereof

An anti-fouling and coating technology, applied in anti-corrosion coatings, anti-fouling/underwater coatings, coatings, etc., can solve the problems of long maintenance cycle, high cost, complex maintenance procedures, etc., to reduce the number of construction passes and maintenance. effect of cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

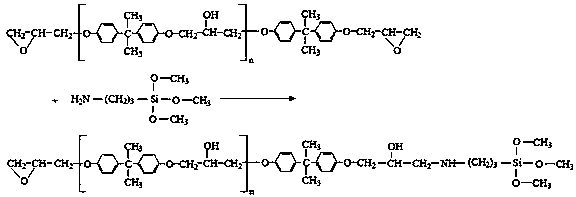

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of the anti-corrosion and anti-fouling integrated coating for coating repair of the present invention comprises the following steps:

[0035] (1) Preparation of anti-corrosion components: first mix epoxy resin, modified epoxy resin, bifunctional reactive diluent, fumed silica and anti-rust pigments and fillers, disperse for 20-40 minutes, add solvent to adjust viscosity, and continue to disperse After 3-5 hours, the material can be discharged after being fully dispersed and evenly distributed. After the material is discharged, it is packaged separately with the amine curing agent.

[0036] (2) Preparation of antifouling components: first add hydroxy silicone resin, phenylmethyl silicone oil, fumed silica and antifouling additives to mix, disperse for 20-40 minutes, add solvent to adjust viscosity, continue to disperse for 3-5 hours , It can be discharged after being fully dispersed and uniform. When using, add silane crosslinking agent in proporti...

Embodiment 1

[0041] By weight percentage, take 30% of epoxy resin, 1% of modified epoxy resin, 30% of bifunctional reactive diluent, 0.5% of fumed silica, 10% of aluminum tripolyphosphate, 4.5% of zinc phosphate, sericite powder 4%, precipitated barium sulfate 5%, amidoamine curing agent 15%. Mix the other raw materials except the amidoamine curing agent, disperse at high speed for 25 minutes, add solvent to adjust to a suitable viscosity, continue to disperse for 3.5 hours, and discharge after fully dispersing evenly;

[0042] By weight percentage, take 75% of hydroxyl silicone resin, 3% of phenylmethyl silicone oil, 3% of fumed silica, 4% of zinc pyrithione, 6% of ECONEA, 3% of Irgarol 1051 and 6% of epoxy silane . Mix the other raw materials except epoxy silane, disperse at high speed for 30 minutes, add solvent to adjust to a suitable viscosity, continue to disperse for 4 hours, fully disperse and evenly discharge.

[0043] Before construction, mix the amine curing agent in the anti-...

Embodiment 2

[0045] By weight percentage, take 20% of epoxy resin, 5% of modified epoxy resin, 35% of bifunctional reactive diluent, 1% of fumed silica, 12% of aluminum tripolyphosphate, 5% of zinc phosphate, and sericite powder 3%, precipitated barium sulfate 1%, polyether amine curing agent 18%. Mix the other raw materials taken except polyetheramine curing agent, disperse at high speed for 40 minutes, add solvent to adjust to a suitable viscosity, continue to disperse for 3 hours, and discharge after fully dispersing evenly;

[0046] By weight percentage, take 78% of hydroxyl silicone resin, 2% of phenylmethyl silicone oil, 2% of fumed silica, 3% of zinc pyrithione, 4% of ECONEA, 4% of Irgarol 1051 and 7% of ketoximosilane . Mix the other raw materials except ketoximosilane, disperse at high speed for 40 minutes, add solvent to adjust to a suitable viscosity, continue to disperse for 3 hours, fully disperse and evenly discharge.

[0047] Before construction, mix the amine curing agent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com