High-manganese CADI and heat treatment method thereof

A technology of high manganese and molten iron, applied in the field of wear-resistant materials, can solve the problems of poor wear uniformity of ductile iron, poor hardenability of ductile iron, poor uniformity of ductile iron hardness, etc., and achieves low cost, complete martensite transformation, and improved hardness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

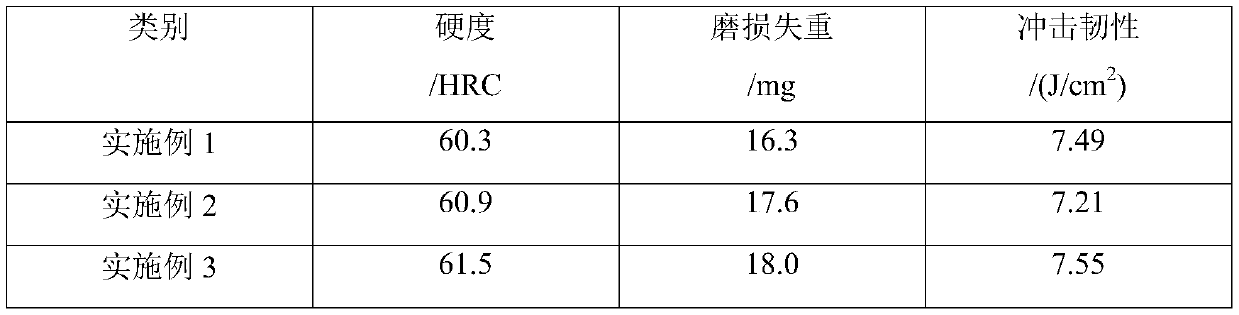

Embodiment 1

[0022] A high-manganese CADI and its heat treatment method are characterized by adopting an electric furnace to smelt molten iron, and the specific preparation process steps are as follows:

[0023] ①First, use an intermediate frequency induction furnace to smelt molten iron with the following chemical composition (wt%): C: 3.10, Mn: 3.25, Si: 2.77, Cr: 1.02, Al: 0.21, Sb: 0.08, 0.031P, 0.026S, the balance Fe; heated to 1485℃, and then transferred to the ladle; pre-placed nodulizer and inoculant in the ladle, and pour the molten iron into the ladle for spheroidization and inoculation by the flushing method; The agent is composed of 82% rare earth magnesium silicon alloy (the chemical composition and mass fraction of rare earth magnesium silicon alloy: 6.02% RE, 8.86% Mg, 35.80% Si, 0.63% Ti, 0.55% Al, the balance is Fe and Trace other impurities) and 18% copper-magnesium alloy (the chemical composition of copper-magnesium alloy and its mass fraction: 32% Mg, 68% Cu), the added am...

Embodiment 2

[0026] A high-manganese CADI and its heat treatment method are characterized by adopting an electric furnace to smelt molten iron, and the specific preparation process steps are as follows:

[0027] ①First, use an intermediate frequency induction furnace to smelt molten iron with the following chemical composition (wt%): C: 3.35, Mn: 3.03, Si: 2.52, Cr: 1.10, Al: 0.24, Sb: 0.05, 0.030P, 0.029S, the balance Fe; heated to 1505℃, and then transferred to the ladle; pre-placed the nodulizer and inoculant in the ladle, and poured the molten iron into the ladle for spheroidization and inoculation by the flushing method; The agent is composed of 82% rare earth magnesium silicon alloy (the chemical composition and mass fraction of rare earth magnesium silicon alloy are: 8.15% RE, 7.05% Mg, 40.29% Si, 0.70% Ti, 0.61% Al, the balance is Fe and Trace other impurities) and 18% copper-magnesium alloy (the chemical composition of copper-magnesium alloy and its mass fraction: 35% Mg, 65% Cu), th...

Embodiment 3

[0030] A high-manganese CADI and its heat treatment method are characterized by adopting an electric furnace to smelt molten iron, and the specific preparation process steps are as follows:

[0031] ①First, use an intermediate frequency induction furnace to smelt molten iron with the following chemical composition (wt%): C: 3.19, Mn: 3.18, Si: 2.71, Cr: 1.06, Al: 0.23, Sb: 0.07, 0.029P, 0.024S, and the balance Fe; heated to 1490℃, then transferred to the ladle; pre-placed spheroidizing agent and inoculant in the ladle, using the flushing method to pour the molten iron into the ladle for spheroidization and inoculation treatment; The agent is composed of 82% rare earth magnesium silicon alloy (the chemical composition and mass fraction of rare earth magnesium silicon alloy: 7.11% RE, 7.94% Mg, 37.23% Si, 0.41% Ti, 0.38% Al, the balance is Fe and Trace other impurities) and 18% copper-magnesium alloy (the chemical composition of copper-magnesium alloy and its mass fraction: 33.8% M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com