In-situ sum frequency vibration spectrum detection device with laser heating

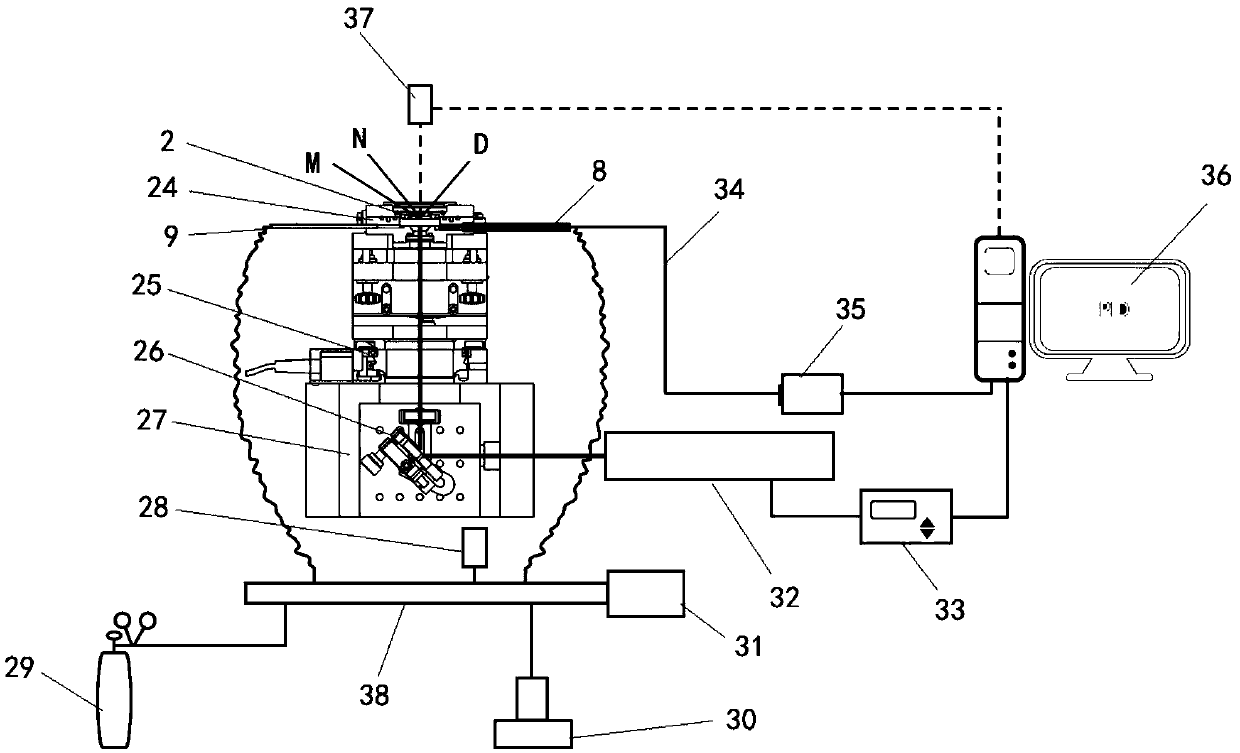

A laser heating and vibrational spectroscopy technology, applied in the field of in-situ and frequency vibrational spectroscopy characterization, can solve the problem of difficult to achieve high temperature and high pressure conditions of the actual catalytic system, complex total internal reflection and frequency vibrational spectroscopy devices, and frequency vibrational spectroscopy signal-to-noise ratio. It can avoid the interference of side reactions, facilitate disassembly and replacement, and achieve the effect of high heating efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] According to the following conditions, the sodium dodecyl sulfate (SDS) sum-frequency vibration spectrum and the influence of annealing temperature on the spectrum were measured on the z-cutα quartz crystal:

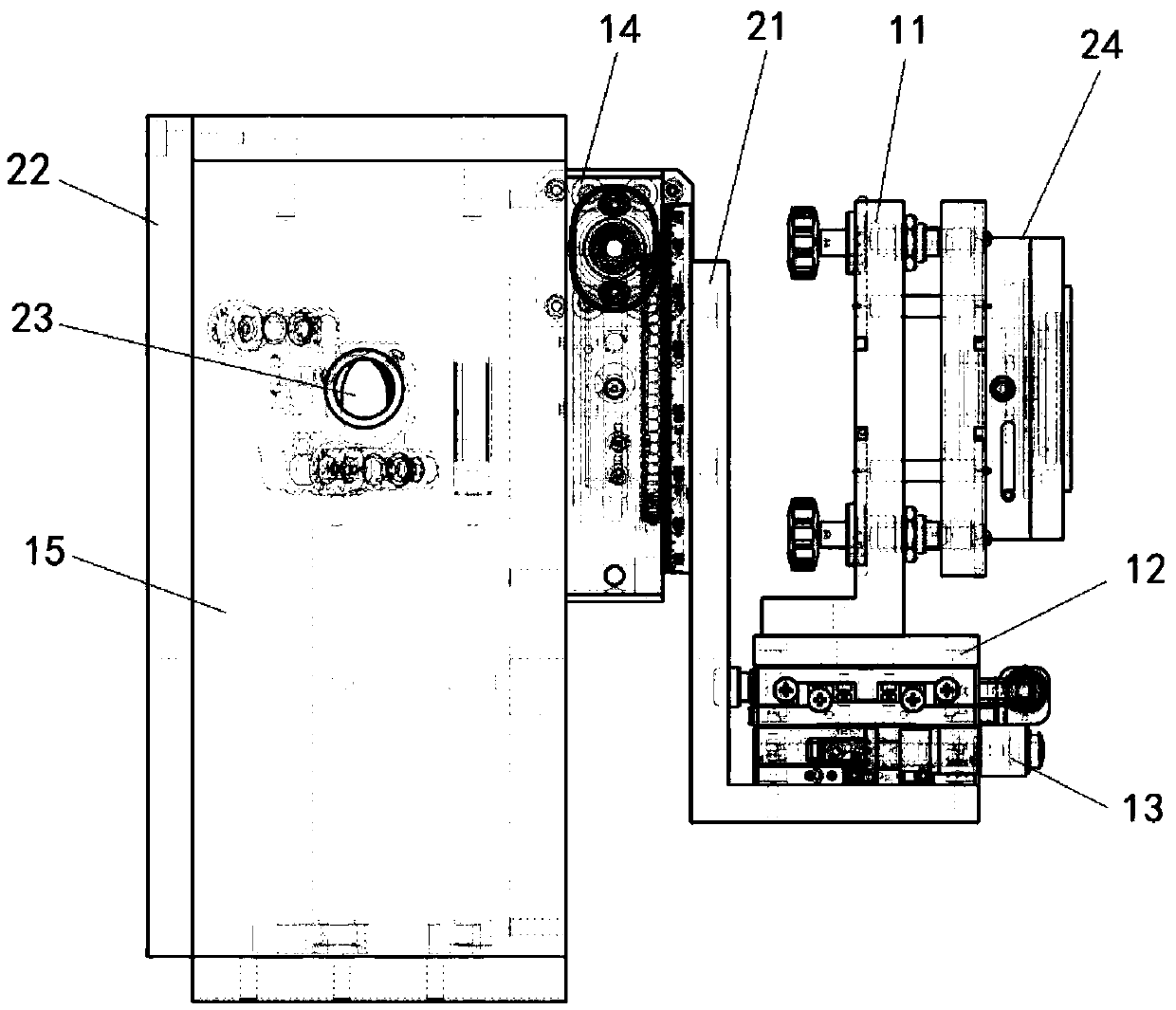

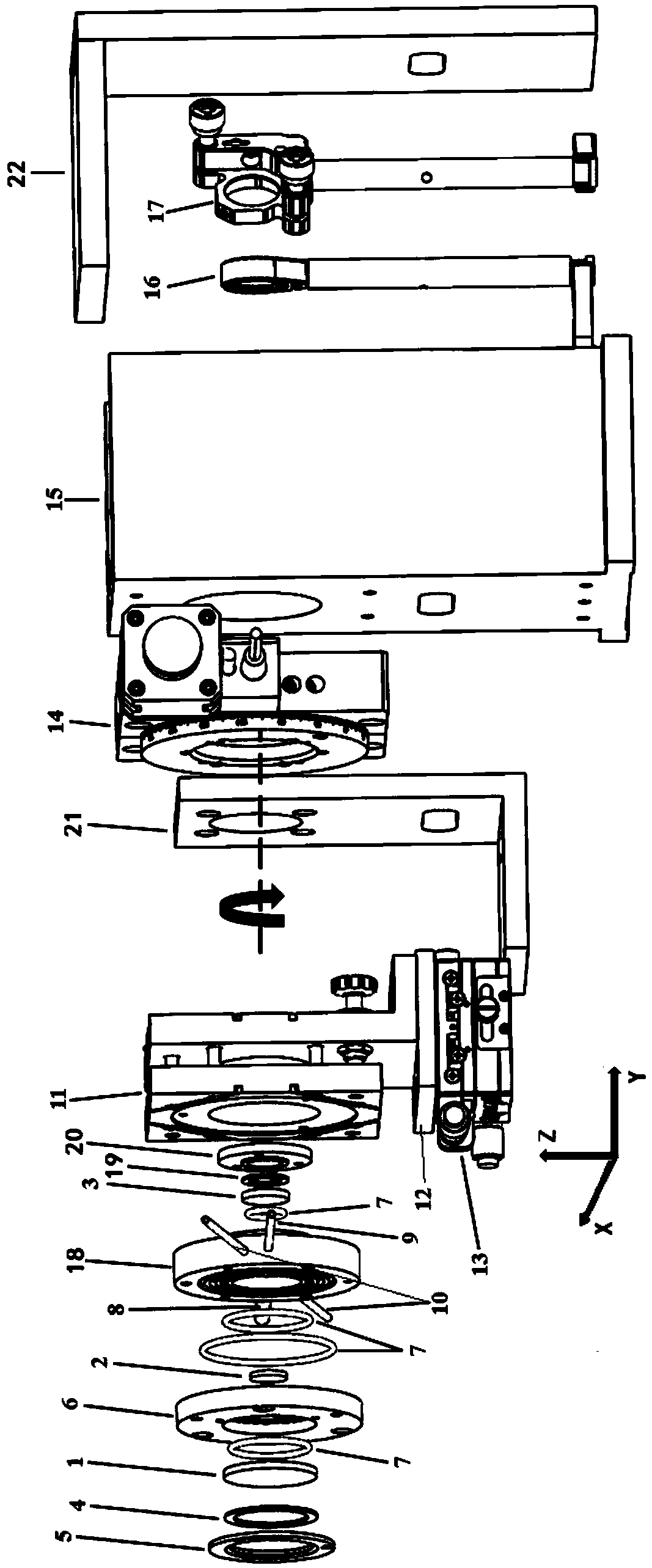

[0045] In this embodiment, the material of the front window 1 is calcium fluoride, the material of the sample 2 is z-cutα quartz crystal, and the material of the rear window 3 and the lens 16 is zinc selenide. Laser 32 for CO 2 For the laser, the temperature measurement method is to use a thermocouple 34 to measure the temperature. The thermocouple 34 is glued to the edge of the rear surface of the quartz crystal to ensure that the heating laser will not directly shine on the thermocouple 34.

[0046] In this embodiment, the size of the quartz crystal is Φ16×2mm, and 15 μL of 0.27 mmol / L SDS ethanol solution is dropped on the surface of the quartz crystal, with an area of about 40 mm. 2 . Then disassemble the stainless steel outer wall, press the quartz crysta...

Embodiment 2

[0050] According to the following conditions, the sum-frequency vibration spectra of z-cutα quartz crystals dropped with Pt nanoparticles under different CO pressures were measured:

[0051] In this embodiment, the material of the front window 1 is calcium fluoride, the material of the sample 2 is z-cutα quartz crystal, and the material of the rear window 3 and the lens 16 is zinc selenide. Laser 32 for CO 2 For the laser, the temperature measurement method is to use a thermocouple 34 to measure the temperature. The thermocouple 34 is glued to the edge of the rear surface of the quartz crystal to ensure that the heating laser will not directly shine on the thermocouple.

[0052] In this embodiment, the size of the quartz crystal is Φ16×2 mm, and the particle size of the Pt nanoparticles used is about 50 nm. Take 1 mg of Pt powder, add 7 mL of ethanol, and ultrasonically obtain the ethanol dispersion of Pt nanoparticles. Take 35 μL of the dispersion and drop it on the surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com