Kefir fermented dairy product and preparation method thereof

A technology for kefir fermented milk and fermented milk products, which is applied in the field of kefir fermented milk products and its preparation, can solve the problems that strains have not been included in the list of strains, optimize strain combinations and process conditions, and enhance development Phil flavor and bubble taste, the effect of improving fermentation metabolites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] In a second aspect, the present invention provides a method for preparing kefir fermented milk products as described in the first aspect, comprising the steps of:

[0040]After the animal milk is cleaned and pre-sterilized in sequence, acid fruit juice and sugar are added, stirred until the sugar is completely dissolved in the animal milk, and then the first homogeneous treatment is carried out. After sterilization and cooling, the compound bacteria are inserted into the Fermentation is carried out to obtain fermented milk, and then a second homogeneous treatment is carried out to obtain kefir fermented milk products.

[0041] In one embodiment, the conditions of the first homogenization treatment are: a homogenization temperature of 60-65° C., and a homogenization pressure of 100-400 bar.

[0042] In one embodiment, the conditions of the second homogenization treatment are: a homogenization temperature of 10-20° C., and a homogenization pressure of 100-400 bar.

[004...

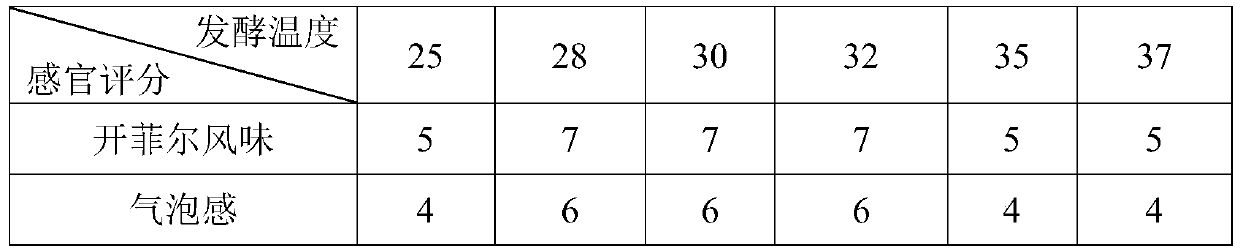

Embodiment 1

[0047] In order to study the fermentation characteristics of different strains, this example adopts the following method to prepare dairy products: Weigh the following raw materials in weight percentage: citric acid concentrated juice (calculated as citric acid) 0.5‰, white sugar 5%, bacteria Seed 0.05‰, the balance of raw milk; after the raw milk has been cleaned and pre-pasteurized, slowly add lemon juice dropwise at 15°C under stirring, and after stirring evenly, add white sugar, and stir until the white sugar is completely After dissolving, homogenize at 60-65°C and 250 bar, sterilize and cool to the fermentation temperature shown in Table 1, then inoculate the strains, heat-preserve and ferment, start stirring for 10 minutes every hour after inoculation, and the fermentation ends in the third hour Stir and continue to ferment until the pH value is 4.6 to obtain fermented milk. After stirring the fermented milk evenly, homogeneously process the fermented milk under the cond...

Embodiment 2

[0052] In order to study the influence of different bacterial species combinations on the sensory evaluation of dairy products, the following method was used in this example to prepare dairy products: Weigh the following raw materials by weight percentage: citric acid concentrated juice (calculated as citric acid) 0.5‰, white 5% granulated sugar, the amount of bacteria added is shown in Table 2, and the remaining amount of raw milk; after the raw milk has been cleaned and pre-pasteurized, slowly add lemon juice dropwise at 15°C while stirring, and stir evenly Finally, add white granulated sugar, stir until the white granulated sugar is completely dissolved, homogenize at 60-65°C and 250bar, sterilize and cool to 28-32°C, inoculate strains, keep warm and ferment, start stirring for 10 hours after inoculation After 3 hours of fermentation, the stirring was stopped, and the fermentation was continued until the pH value was 4.6 to obtain fermented milk. After the fermented milk was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com