System for preparing compound amino acid from waste protein through microwave acidolysis

A compound amino acid and waste protein technology, which is applied in the field of microwave acid hydrolysis of waste protein to prepare compound amino acid system, can solve the problems of single cost of protein source and inability to directly utilize protein source, so as to relieve the pressure of protein demand, improve utilization efficiency, The effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

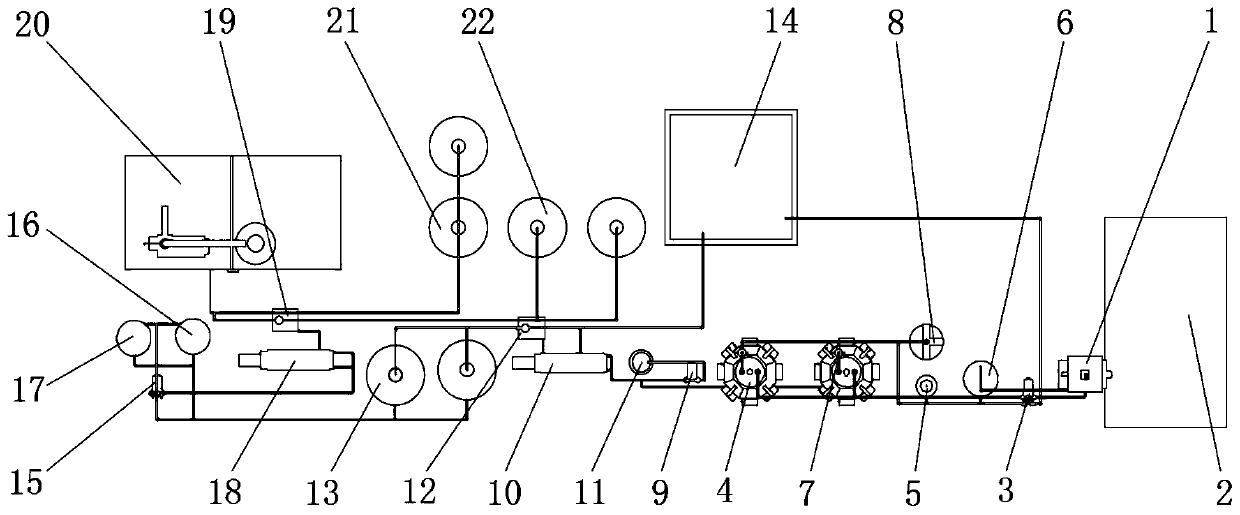

[0023] see figure 1 , the present embodiment provides a system for preparing compound amino acids by microwave acidolysis of waste protein, comprising a screw extrusion separator 1 and a crude fiber temporary storage pool 2, the screw extrusion separator 1 is connected with a first electric diaphragm pump 3 through a pipeline, The first electric diaphragm pump 3 is connected with a microwave hydrolysis reaction kettle 4 through a pipeline, the microwave hydrolysis reaction kettle 4 is connected with a hydrochloric acid tank 5 and an organic liquid temporary storage tank 6 through a pipeline, and the microwave hydrolysis reaction kettle 4 is connected with a second electric diaphragm pump through a pipeline 9. The second electric diaphragm pump 9 is connected to a plate and frame filter press 10 through a pipeline, and the plate and frame filter press 10 is connected to a first submerged anticorrosion pump 12 through a pipeline, and the first submerged anticorrosion pump 12 is c...

Embodiment 2

[0033] see figure 1 , made further improvement on the basis of embodiment 1: microwave hydrolysis reactor 4 is connected with glass condenser 7 by pipeline, and glass condenser 7 is connected with condensate temporary storage tank 8 by pipeline, by glass condenser 7, can make The utilization efficiency of the hydrochloric acid is increased by more than 50%, which greatly reduces the use cost of the neutralization reaction alkali, and can prevent the acid liquid from polluting the environment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com