Heating ceramic tile and preparing method thereof

A ceramic tile and heating paint technology, applied in the field of materials, can solve the problems of long heating time, unsuitable for batch production, unstable heat transfer, etc., and achieve the effect of easy laying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

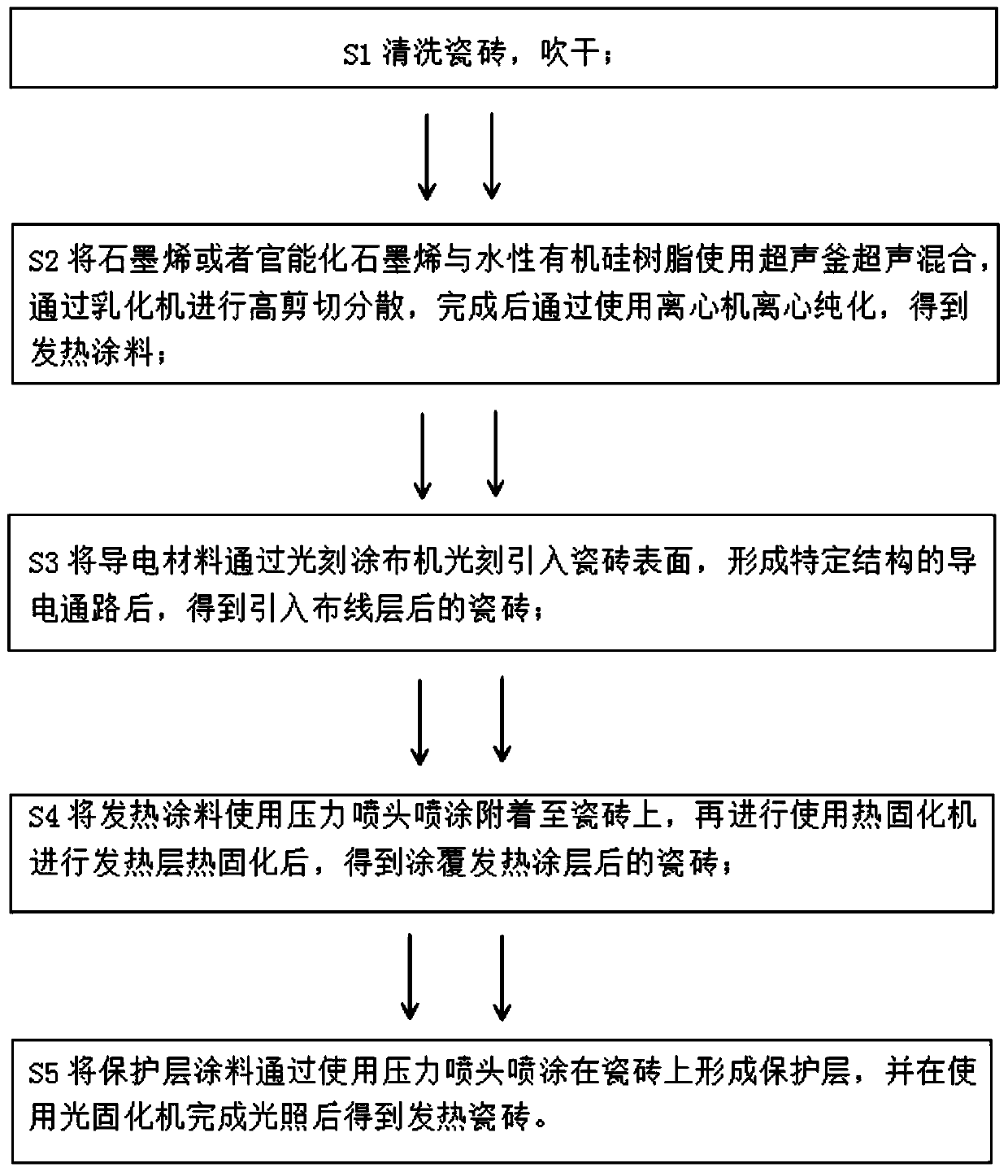

[0024] Please refer to figure 1 , a method for preparing a heating tile provided in an embodiment of the present invention, comprising the following steps:

[0025] S1 uses the unpacking machine to unpack the tiles. The unpacking machine includes a positioning system and a dismantling robot arm. The size of the tiles is calculated through the positioning system, and the robotic arm is further driven to perform dismantling actions. The tiles of different specifications and sizes are passed through the unpacking machine. Disassemble the outer packaging, put it on the conveyor belt and send it to the next process. The size of the tiles involved is from 1mm*1mm-1200mm*2400mm. After that, use the shower head to clean the tiles, and remove the particles and dust on the back of the tiles. The spray head pumps water mist with a certain pressure through the booster pump, so that the particles on the tiles are dissolved or taken away by the flowing droplets, and the cleaned tiles are ...

Embodiment 1

[0032] A method for preparing a heating tile according to this embodiment comprises the following steps:

[0033] S1 Unpack the 120mm*120mm tiles, and then use the spray head to clean the tiles, remove the particles and dust on the back of the tiles, and blow the cleaned tiles with high-pressure air until the surface is completely dry until;

[0034] S2 Use an ultrasonic kettle to mix the fluorinated graphene and water-based silicone resin by ultrasonic stirring. The ultrasonic time is 100Min and the ultrasonic power is 500W. Then the material is sent into the reactor for high-shear dispersion. After completion, the material is sent to the centrifuge to settle the poorly dispersed particles. Wherein the centrifugal speed of the centrifuge is 1000rpm, and the duration is 10min, and then the heating coating is obtained.

[0035] S3 introduces the carbon conductive tape into the surface of the tiles by using a photolithography coater through mask spraying, the wiring thickness ...

Embodiment 2

[0040] A method for preparing a heating tile according to this embodiment comprises the following steps:

[0041]S1 Unpack the 80mm*80mm tiles, and then use the spray head to clean the tiles, remove the particles and dust on the back of the tiles, and blow the cleaned tiles with high-pressure air until the surface is completely dry until;

[0042] S2 Use an ultrasonic kettle to mix the graphene material and water-based silicone resin by ultrasonic stirring. The ultrasonic power is 400W for 80 minutes, and then the material is sent to the reactor for high-shear dispersion. Send the material into the centrifuge to settle the poorly dispersed particles. Wherein the centrifugal speed of the centrifuge is 1000rpm, and the duration is 10min, and then the heating coating is obtained.

[0043] S3 introduces conductive carbon black into the surface of the ceramic tile by using a direct-writing photolithography machine through mask spraying, the wiring thickness is 100u, and the wirin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thermal power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com