A forced convection solar heat flux density homogenization device and method thereof

A technology of heat flux and forced convection, which is applied in solar thermal energy, solar thermal power generation, solar collectors, etc., can solve the problems of low heat transfer efficiency, highly uneven sunlight heat flux, and large heat loss, so as to improve uniformity , reasonable structure, and the effect of reducing the peak heat flux density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

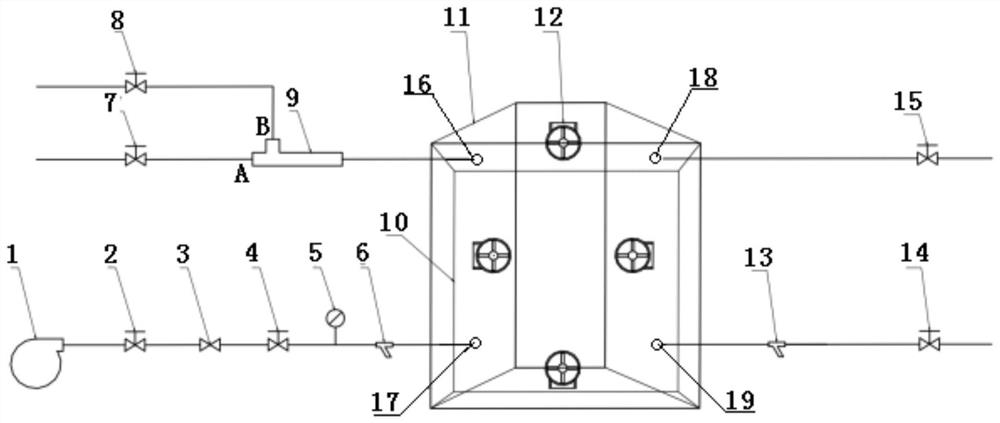

[0027] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0028] see figure 1 , a forced convection solar heat flux uniformization device, including a cavity heat absorber 11, the front wall of the cavity type heat absorber 11 is provided with a window 10, inside the cavity type heat absorber 11, the upper, lower, left, A fan 12 is installed at the center of the four right walls to change the flow state inside the cavity from natural convection to forced convection; one side of the cavity heat absorber 11 is provided with an inlet device connected to the feed port 16 and a pressure balance device connected to the pressure balance port 17 , the other side of the cavity heat absorber 11 is provided with a sampling device connected to the sampling port 18 and an outlet device connected to the discharge port 19 .

[0029] The inlet device comprises a first feed valve 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com