Positive temperature coefficient type piezoresistor

A positive temperature coefficient, varistor technology, applied to resistors, varistors, varistor cores with positive temperature coefficients, etc. problems, to achieve the effect of excellent working performance and excellent working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The specific steps of the manufacturing method of the above-mentioned positive temperature coefficient type varistor are:

[0023] 1. Preparation of main ingredients: To prepare 3000 grams of mixed powder, take the raw material powder in proportion: 2749.808 grams of ZnO, 130.473 grams of Bi 2 o 3 , 14.010 g TiO 2 , 46.478 g Co 2 o 3 , 5.840 g Ni 2 o 3 , 8.050 g MnCO 3 , 10.610 g SnO 2 , 6.562 grams of Al(NO 3 ) 3 9H 2 O, 25.549 g Sb 2 o 3 , 1.036 g SrCO 3 , 1.736 g H 3 BO 3 , respectively weighed well, mixed evenly, as the main ingredient A;

[0024] 2. Preparation of slurry: Mix 7.5g of dispersant polyacrylic acid and 2000g of deionized water, heat and stir in a water bath at 80°C until the polyacrylic acid is completely dissolved, adjust the pH value to 8 with diluted acetic acid and ammonia water, and obtain solution B. Put the main ingredient A, solution B and 9000g zirconium balls into a ball mill tank, and wet ball mill for 16 hours to obtain a mi...

Embodiment 2

[0030] The specific steps of the manufacturing method of the above-mentioned positive temperature coefficient type varistor are:

[0031] 1. Preparation of main ingredients: To prepare 3000 grams of mixed powder, take the raw material powder according to the proportion: 2698.906 grams of ZnO, 128.058 grams of Bi 2 o 3 , 21.984 g TiO 2 , 57.022 g Co 2 o 3 , 16.900 g Ni 2 o 3 , 6.767 g BaCO 3 , 11.851 g MnCO 3 , 14.523 g SnO 2 , 12.881 grams of Al(NO 3 ) 3 9H 2 O, 30.091 g Sb 2 o 3 , 1.017 g SrCO 3 , respectively weighed well, mixed evenly, as the main ingredient A;

[0032] 2. Preparation of slurry: Mix 7.5g of dispersant polyacrylic acid and 2300g of deionized water, heat and stir in a water bath at 80°C until the polyacrylic acid is completely dissolved, adjust the pH value to 8 with diluted acetic acid and ammonia water, and obtain solution B. Put the main material A, solution B and 9000g zirconium balls into a ball mill jar, and wet ball mill for 16 hours to ...

Embodiment 3

[0040] In order to detect the advantages of the present invention for traditional varistors, the performance tests of the present invention and traditional varistors were carried out and compared:

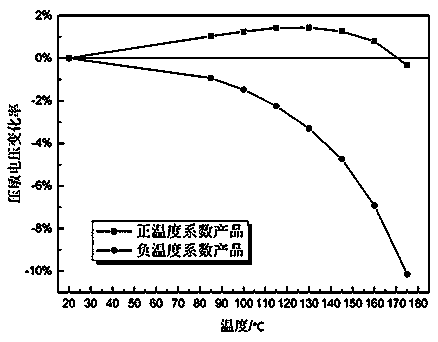

[0041] Such as image 3 Shown is the relationship curve between the varistor voltage change rate and the ambient temperature of the varistor proposed by the present invention and the traditional varistor with the same specification.

[0042] Depend on image 3 It can be seen that the varistor voltage of traditional negative temperature coefficient products begins to decrease rapidly with the increase of temperature from 85°C, and the change rate of the varistor voltage has exceeded 10% at 170°C. However, the varistor voltage of the varistor of the present invention is still close to the initial varistor voltage at 170°C.

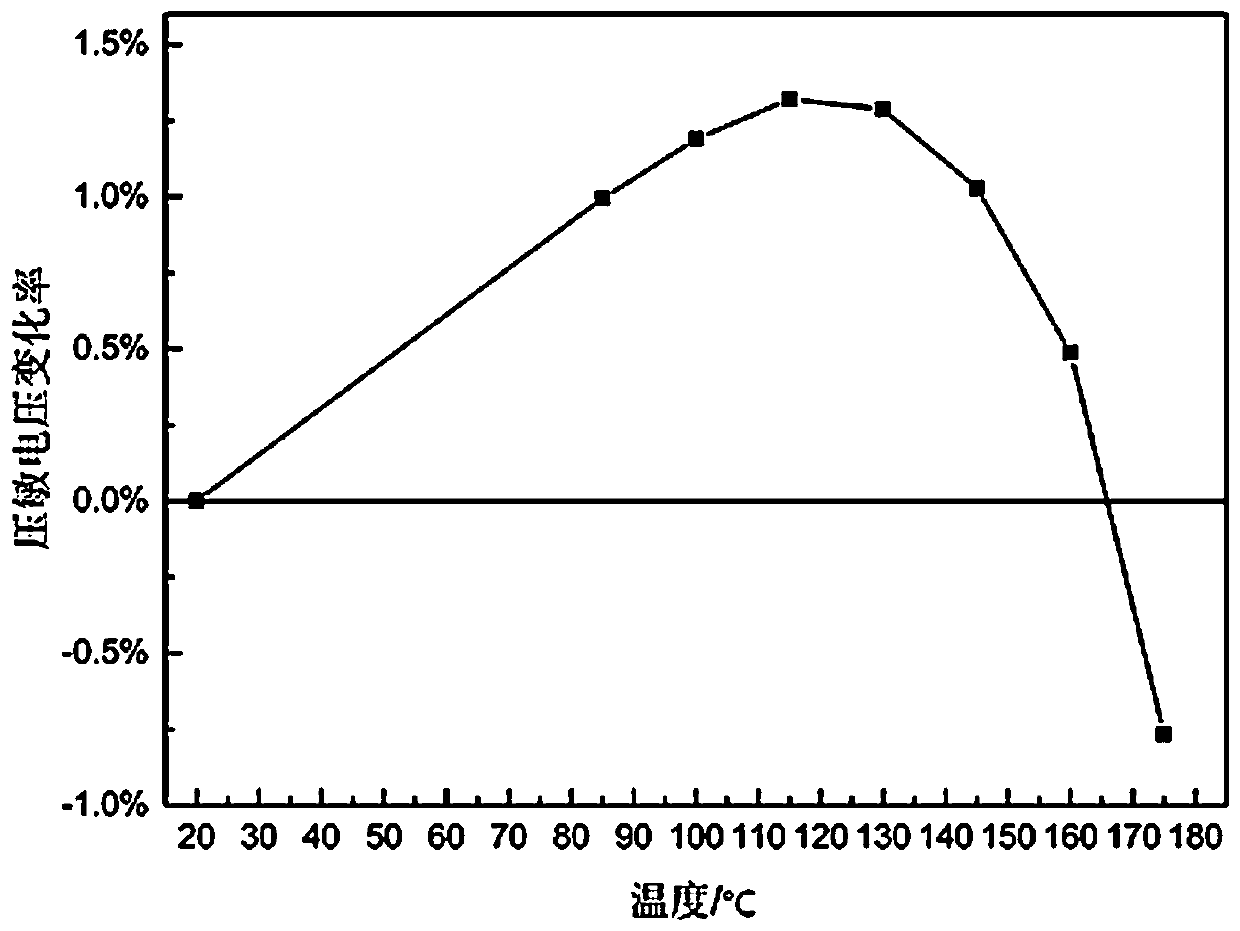

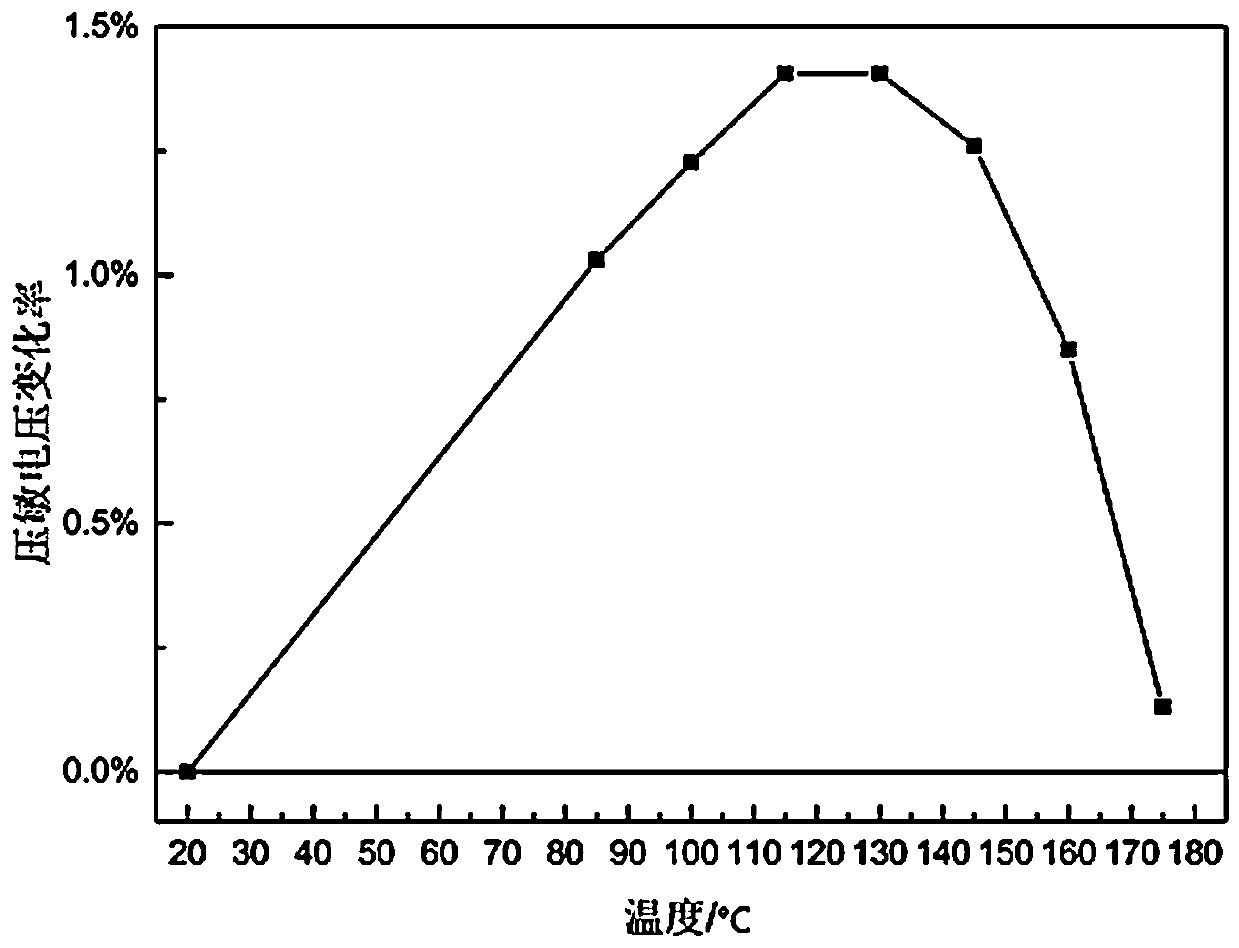

[0043] Figure 4 , Figure 5 Shown is the aging condition of the varistor proposed by the present invention and the traditional varistor of the same specific...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com