Activated carbon in-situ cyclic adsorption regeneration process for advanced treatment of sewage plant

A technology of activated carbon adsorption and advanced treatment, applied in water/sewage treatment, adsorbed water/sewage treatment, water/sludge/sewage treatment, etc., to achieve the effect of small mass loss, complete recovery of adsorption value and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

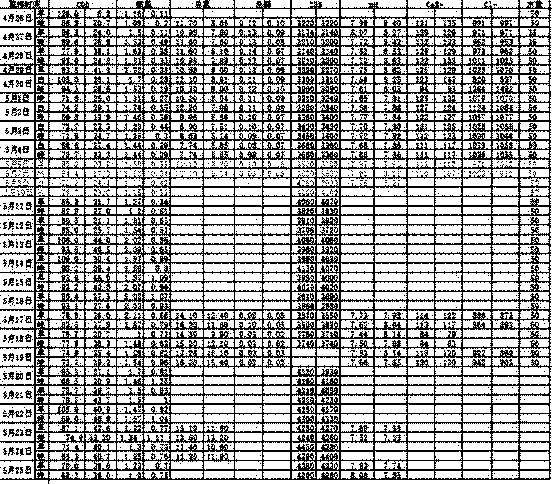

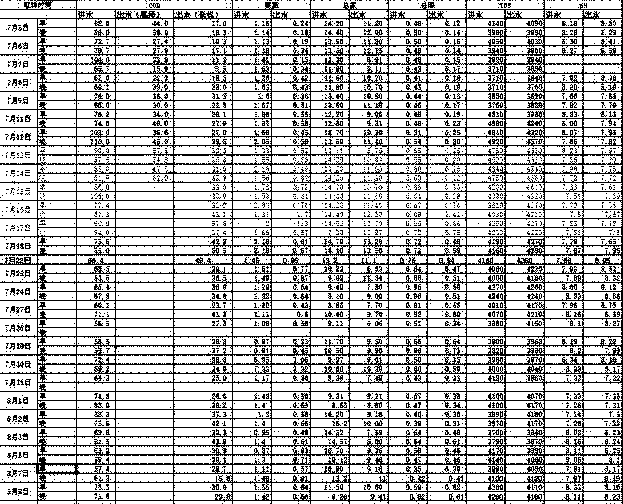

Embodiment 1

[0026] An activated carbon in-situ cyclic adsorption regeneration process for advanced treatment of sewage treatment plants, comprising the following steps:

[0027] S1: The sewage in the sewage plant is injected into the activated carbon adsorption device as raw water, the hydraulic retention time is 1h, the CODcr index of the raw water influent is 120mg / L, and the CODcr index of the raw water effluent is 40mg / L;

[0028] S2: When the CODcr index value of the raw water effluent exceeds 40mg / L for three consecutive days, replace the activated carbon filler in the activated carbon adsorption device;

[0029] S3: put the activated carbon filler replaced in S2 into the activated carbon regeneration furnace to carry out high-temperature impurity desorption for 30 minutes, wherein the activated carbon regeneration furnace temperature is 750 ° C, and is in an oxygen-free state;

[0030] S4: The activated carbon filler treated in S3 is added to the activated carbon adsorption device ...

Embodiment 2

[0037] An activated carbon in-situ cyclic adsorption regeneration process for advanced treatment of sewage treatment plants, comprising the following steps:

[0038] S1: The sewage in the sewage plant is injected into the activated carbon adsorption device as raw water, the hydraulic retention time is 1h, the CODcr index of the raw water influent is 90mg / L, and the CODcr index of the raw water effluent is 20mg / L;

[0039] S2: When the CODcr index value of the raw water effluent exceeds 40mg / L for three consecutive days, replace the activated carbon filler in the activated carbon adsorption device;

[0040] S3: put the activated carbon filler replaced in S2 into the activated carbon regeneration furnace to carry out high-temperature impurity desorption for 30 minutes, wherein the activated carbon regeneration furnace temperature is 850 ° C, and is in an oxygen-free state;

[0041] S4: The activated carbon filler treated in S3 is added to the activated carbon adsorption device i...

Embodiment 3

[0049] An activated carbon in-situ cyclic adsorption regeneration process for advanced treatment of sewage treatment plants, comprising the following steps:

[0050] S1: The sewage in the sewage plant is injected into the activated carbon adsorption device as raw water, the hydraulic retention time is 1h, the CODcr index of the raw water influent is 60mg / L, and the CODcr index of the raw water effluent is 20mg / L;

[0051] S2: When the CODcr index value of the raw water effluent exceeds 40mg / L for three consecutive days, replace the activated carbon filler in the activated carbon adsorption device;

[0052] S3: put the activated carbon filler replaced in S2 into the activated carbon regeneration furnace to carry out high-temperature impurity desorption for 30 minutes, wherein the activated carbon regeneration furnace temperature is 850 ° C, and is in an oxygen-free state;

[0053] S4: The activated carbon filler treated in S3 is added to the activated carbon adsorption device i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Iodine value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com