Method and device for improving selectivity of production of low-carbon olefin from methanol conversion

A low-carbon olefin and methanol conversion technology, which is applied in the direction of hydrocarbon production from oxygen-containing organic compounds, organic chemistry, chemical recovery, etc., can solve the uneven distribution of active species in the "hydrocarbon pool", which affects catalytic activity and selectivity, and low-carbon Solve problems such as poor selectivity of olefins, achieve the effect of promoting ideal reactions, improving the distribution of active species, and improving reaction selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

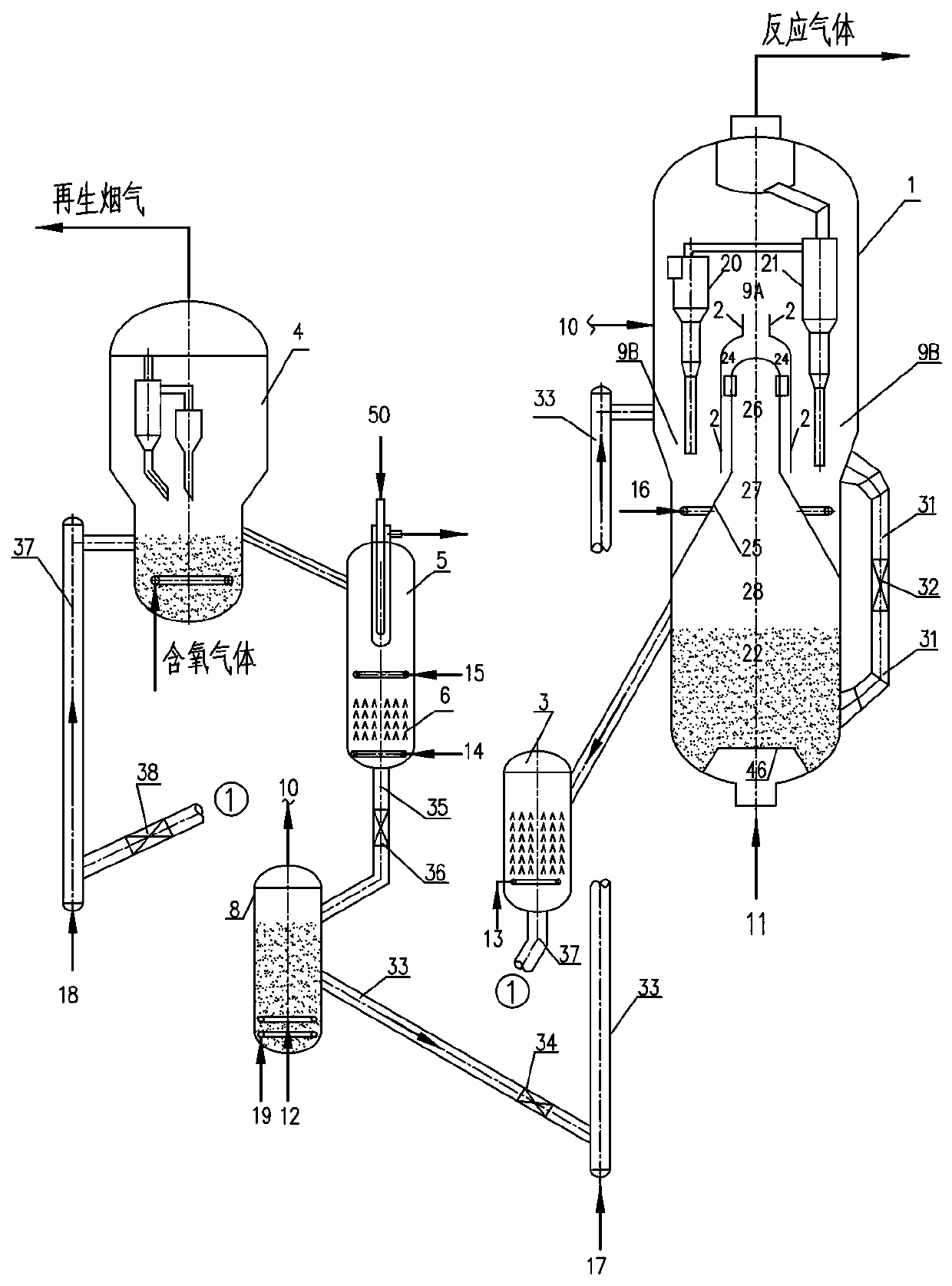

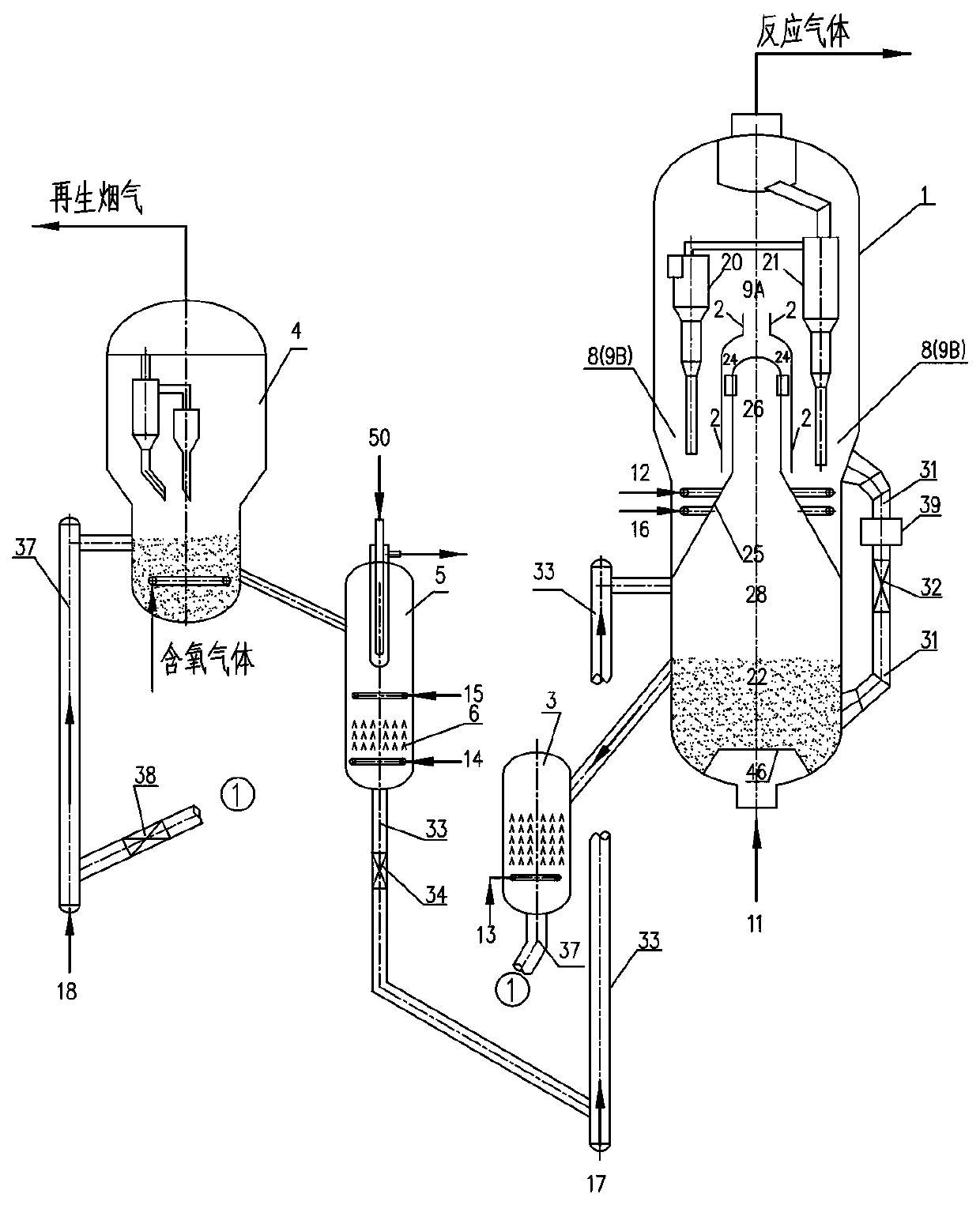

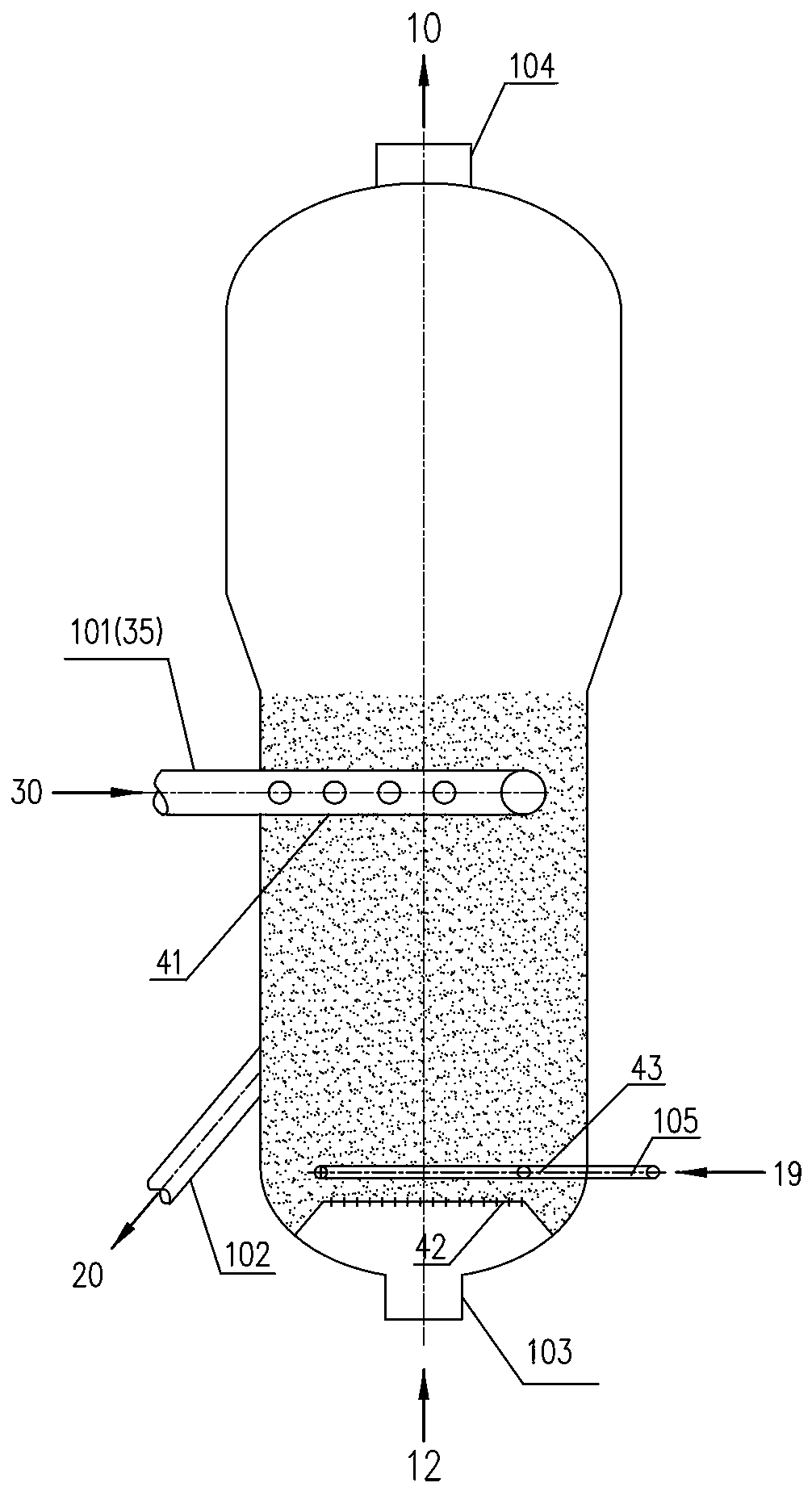

[0120] For example 1, the raw material is methanol, using figure 1 In the process flow shown, the conversion reactor adopts conventional operating conditions, the catalyst is SAPO-34, and the reaction gas is the activation medium. The main operating conditions of the pre-hydrocarbon pooling facility are as follows: the apparent linear velocity is 0.1-0.2m / s, and the reaction temperature is ~460℃, contact time 30~40 minutes.

[0121] Simulation results show that after adding the pre-hydrocarbon pooling facility of the present invention, compared with the existing MTO technology, the low-carbon olefins of the present invention (C 2 = +C 3 = ) selectivity increased by 3.1 percentage points.

[0122] The main parameters and effect comparison are shown in Table 1.

[0123] Table 1

[0124] parameter Existing MTO Technology this invention Conversion reaction temperature °C 480 480 Regeneration temperature ℃ 680 680 Agent / alcohol specific gravi...

example 2

[0126] For example 2, the raw material is methanol, using figure 1 In the process flow shown, the conversion reactor adopts conventional operating conditions, the catalyst is SAPO-34, and the reaction gas is the activation medium. The main operating conditions of the pre-hydrocarbon pooling facility are as follows: the apparent linear velocity is 0.1-0.2m / s, and the reaction temperature is ~460℃, contact time 60~80 minutes.

[0127] Simulation results show that after adding the pre-hydrocarbon pooling facility of the present invention, compared with the existing MTO technology, the low-carbon olefins of the present invention (C 2 = +C 3 = ) selectivity increased by 5.7 percentage points.

[0128] The main parameters and effect comparison are shown in Table 1.

[0129] Table 2

[0130] parameter Existing MTO Technology this invention Conversion reaction temperature °C 480 480 Regeneration temperature ℃ 680 680 Agent / alcohol specific gravi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com