Foam enhancer for micro-foam drilling fluid as well as preparation method and application thereof

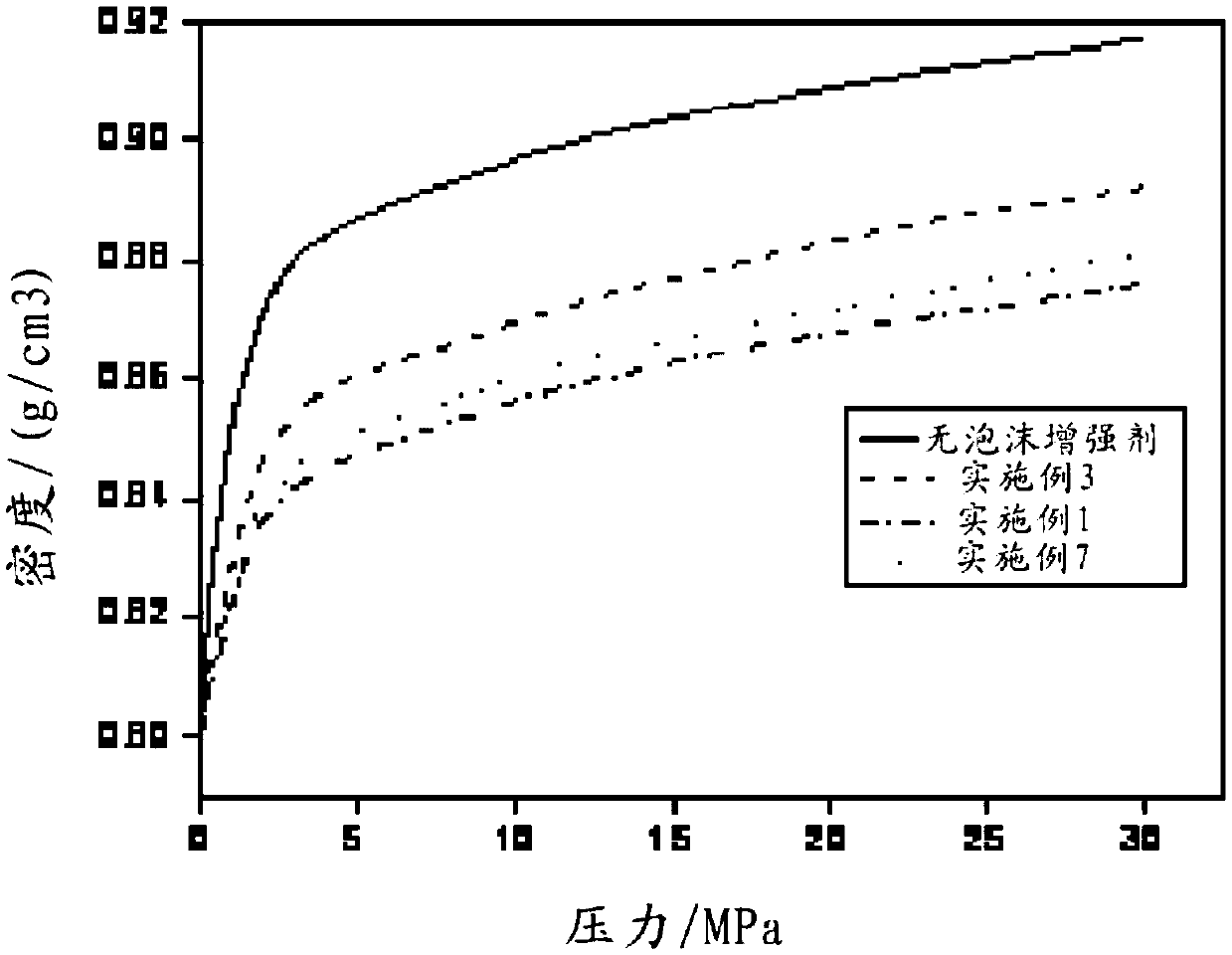

A drilling fluid and enhancer technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problem of insufficient stability and compression resistance of micro-bubble drilling fluid, affect the leak-proof performance of micro-bubble drilling fluid, and affect drilling To solve problems such as liquid construction safety, achieve the effects of increasing the arrangement density and microbubble wall thickness, improving air core sealing, enhancing stability and compression resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Dissolve 10g of dodecyldimethylallyl ammonium chloride in 100g of clear water for use, and dissolve 80g of acrylamide and 10g of 2-acrylamido-2-methylpropanesulfonic acid in 250g of clear water for use ; 1g of ammonium persulfate is dissolved in 50g of clear water for use;

[0049] Add 0.1 g of mercaptoacetic acid and the above dodecyldimethylallyl ammonium chloride solution, acrylamide and 2-acrylamido-2-methylpropanesulfonic acid solution into the reactor and raise the temperature to 60°C, Then the ammonium persulfate solution was added to the reaction system, the temperature of the system was raised to 90° C. for 1 hour, and the pH value of the solution was adjusted to 8 with NaOH to obtain a foam enhancer for microfoam drilling fluid with a solid content of 20%.

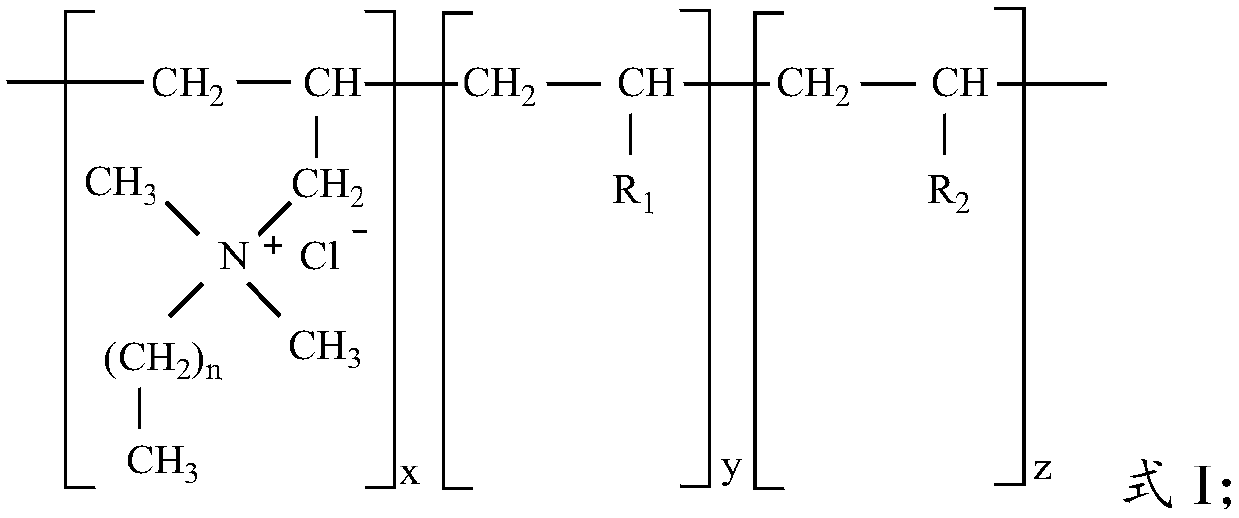

[0050] The structure of the foam enhancer for microfoam drilling fluid prepared in Example 1 of the present invention was tested for its structure. The test result showed that the structure of the foam enh...

Embodiment 2

[0060] Dissolve 5g of tetradecyldimethylallyl ammonium chloride in 50g of clear water for use; dissolve 70g of acrylic acid and 25g of 2-acryloyloxybutylsulfonic acid in 200g of clear water for use; dissolve 0.2g Potassium persulfate is dissolved in 50g of clear water for later use;

[0061] Add 0.5g of ferric chloride, the above tetradecyl dimethyl allyl ammonium chloride solution, the above acrylic acid and 2-acryloyloxybutyl sulfonic acid solution into the reaction vessel and raise the temperature to 50°C, and then add potassium persulfate The solution was added to the reaction system, the temperature of the system was raised to 95° C. and reacted for 2 hours, and the pH value of the solution was adjusted to 9 with NaOH to obtain a foam enhancer for microfoam drilling fluid with a solid phase content of 25%.

[0062] The foam enhancer for microfoam drilling fluid prepared in Example 2 of the present invention is tested for results, and the test result is that the structural...

Embodiment 3

[0066] Dissolve 20g of cetyldimethylallyl ammonium chloride solution in 100g of clear water for use; dissolve 40g of acrylic acid and 40g of 2-acrylamido-2-methylpropanesulfonic acid in 800g of clear water for use ; Dissolve 2g of ammonium persulfate in 100g of clear water for later use;

[0067] Add 0.03 g of dodecyl mercaptan, the above cetyl dimethyl allyl ammonium chloride solution, acrylic acid and 2-acrylamido-2-methylpropanesulfonic acid solution into the reaction vessel and heat up to 70 ℃, then the above ammonium persulfate solution was added to the reaction system, the system was heated to 100 ℃ for 0.5 hours, and the pH value of the solution was adjusted to 10 with NaOH to obtain a foam enhancer for microfoam drilling fluid with a solid phase content of 10%. .

[0068] Structural testing of the foam enhancer for microfoam drilling fluid prepared in Example 3 of the present invention is carried out, and the test result is that the structural formula of the foam enha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com