Special color master batch for polyethylene water supply pipe, preparation method and applications thereof

A technology for water supply pipes and color masterbatches, which is applied in the field of special color masterbatches for polyethylene water supply pipes and its preparation. It can solve the problems of plastic matrix performance and appearance, and the inability to effectively improve the clarity of laser marking, etc., to achieve performance No adverse effect on appearance, improved edge definition, and good surface finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3 and comparative example 1~4

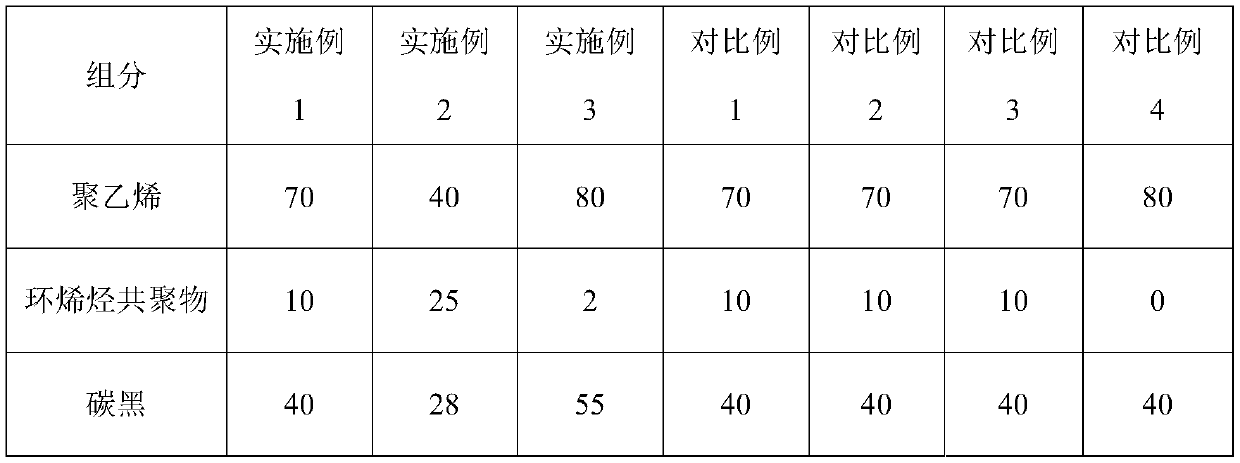

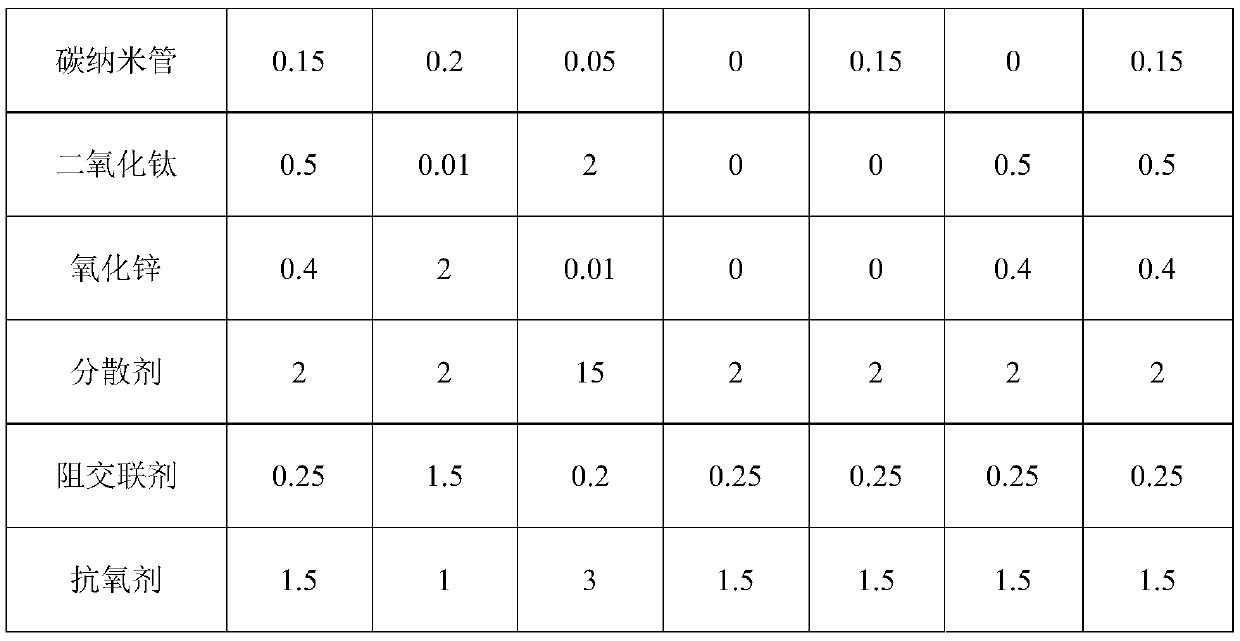

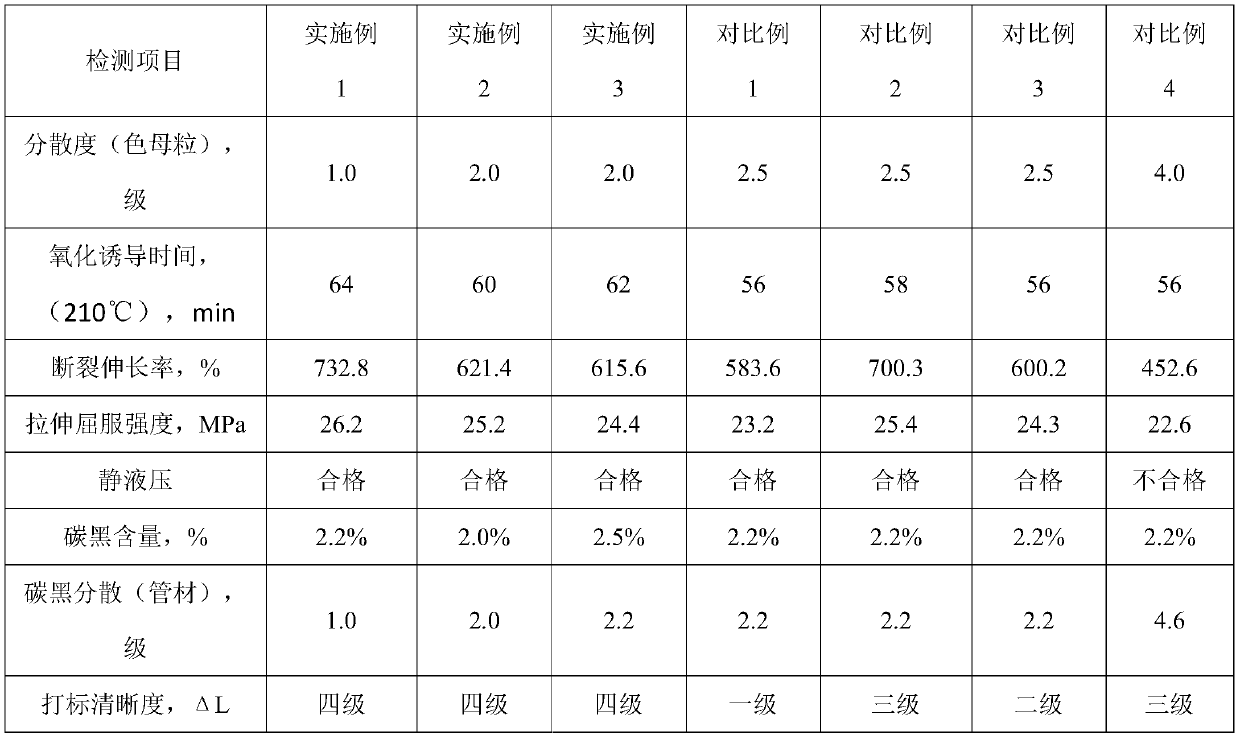

[0032] The present invention provides the raw material ratios of Examples 1-3 and Comparative Examples 1-4 as shown in Table 1 (each component is calculated in parts by weight).

[0033] Table 1 Embodiment 1~3 and comparative example 1~4 raw material proportioning (each component is counted in parts by weight)

[0034]

[0035]

[0036] Among them, polyethylene uses PE100 grade resin, and its melt index is 0.2-0.35g / 10min; carbon black uses 20-25nm furnace carbon black; compatibilizing resin uses cycloolefin copolymer, which is TOPAS 6013 from American Ticona Corporation. Its volume flow index (260°C / 2.16kg) is 12-15mL / 10min; titanium dioxide is selected as an oily rutile nano-titanium dioxide dispersion with a solid content of 30%; zinc oxide is an oily nano-zinc oxide liquid with a solid content of 25%; The dispersant is polyethylene wax 617A; the antioxidant is made of hindered phenolic antioxidant 1010 and phosphite antioxidant 168 according to the mass ratio of 1:1;...

Embodiment 4

[0052] An embodiment of the color masterbatch of the present invention, the proportion and preparation method of the color masterbatch described in this embodiment are the same as those in Example 1. The polyethylene uses PE100 grade resin, and its melt index is 0.2-0.35g / 10min; the carbon black uses 20-25nm furnace carbon black; The flow index (260°C / 2.16kg) is 12-15mL / 10min; the titanium dioxide is selected as an oily rutile nano-titanium dioxide dispersion with a solid content of 30%; the zinc oxide is an oily nano-zinc oxide liquid with a solid content of 25%. The difference is:

[0053] The dispersant used in this example is fatty acid ester wax; the antioxidant is made of hindered phenolic antioxidant 1010 and phosphite antioxidant 168 at a mass ratio of 2:1; the carbon nanotubes are double-walled carbon nanotubes; dimethylamine is selected as the blocking cross-linking agent.

Embodiment 5

[0055] An embodiment of the color masterbatch of the present invention, the proportion and preparation method of the color masterbatch described in this embodiment are the same as those in Example 1. The polyethylene uses PE100 grade resin, and its melt index is 0.2-0.35g / 10min; the carbon black uses 20-25nm furnace carbon black; The flow index (260°C / 2.16kg) is 12-15mL / 10min; the titanium dioxide is selected as an oily rutile nano-titanium dioxide dispersion with a solid content of 30%; the zinc oxide is an oily nano-zinc oxide liquid with a solid content of 25%. The difference is:

[0056] The dispersant in this example is made of barium stearate, zinc stearate, magnesium stearate and calcium stearate in a mass ratio of 1:1:1:1; the antioxidant is hindered phenolic antioxidant Antioxidant 1010 and phosphite antioxidant 168 are compounded at a mass ratio of 2:1; carbon nanotubes are a mixture of single-walled carbon nanotubes and double-walled carbon nanotubes at a ratio of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com