A kind of preparation method of metal magnetic powder core

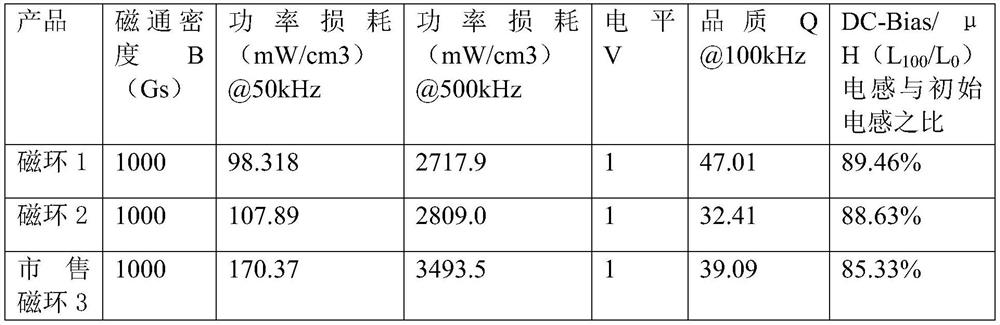

A magnetic powder core and magnetic powder technology, applied in the manufacture of inductors/transformers/magnets, magnetic objects, magnetic materials, etc., can solve the problems of low saturation magnetic induction intensity, low forming density and low magnetic permeability of composite materials, and achieve fluidity. Good, high molding density, improve the effect of magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The method of preparing the metal magnetic powder core in this embodiment sequentially comprises the following steps:

[0032] 1) Configure the phosphoric acid solution: the phosphoric acid and the solvent ratio are 1: 5, where the solvent in the phosphoric acid solution is ethanol;

[0033] Configure a chromic acid solution: chromic acid and solvent ratio of 1:10, solvent in the chromic acid solution is deionized water;

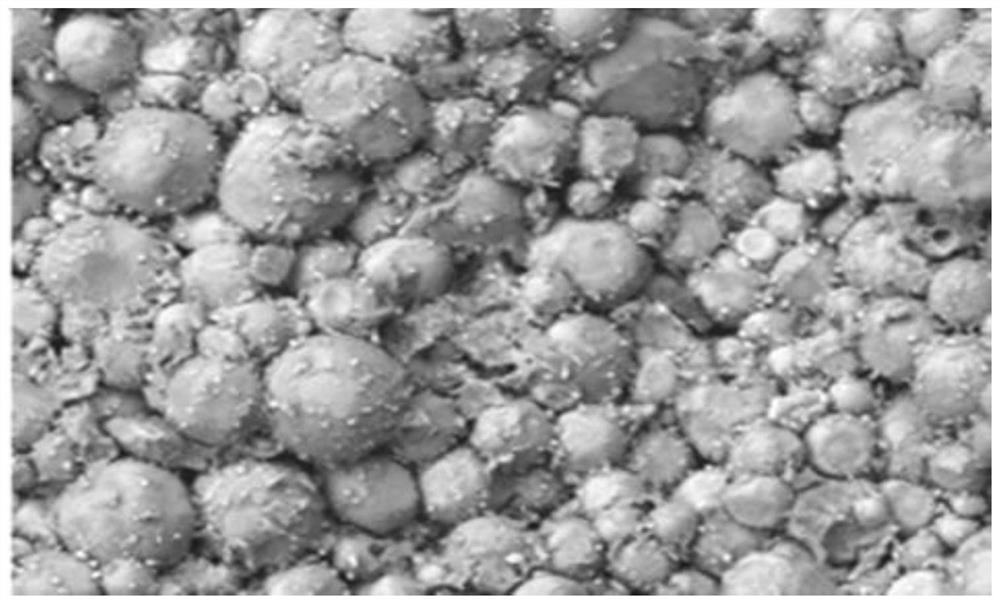

[0034] 2) Magnetic powder slurry: add 1.5% phosphoric acid solution in a certain amount of iron nickel powder, followed by continuous stirring, and mix well until 5min, the initial magnetic powder slurry is continuously stirred until the initial magnetic powder slurry is dried; Then, a 2% chromic acid solution was added in the dry initial magnetic powder slurry, followed by continuous stirring, and mixed well until 15min, formed a ferrous nickel magnetic powder slurry, and then stirred until the iron nickel magnetic powder slurry dry The percentage of the a...

Embodiment 2

[0046] The metal magnetic powder core powder employed in this example is a ferrite magnetic powder and a ferrite molybdenum magnetine powder, wherein the iron nickel magnetic powder is a commercially purchased ordinary aerosol powder, including nickel 45 wt%; iron nickel molybdenum powder containing 81% 2% molybdenum, the rest is iron; the particle size of the two magnetic powders is in the range of 5 to 25 μm. In this example, the particle size of the base powder is 3 to 15 um, wherein the proportion of particle size is 5 to 9um. No less than 55%; the particle size of the nano oxide is in 50 to 500 nm, and one or several of nano-tri-aluminum, silica and titanium dioxide can be used in the present embodiment. In the middle, nano oxide is nano-three oxide.

[0047] The method of preparing the metal magnetic powder core in this embodiment sequentially comprises the following steps:

[0048] 1) Configure the phosphoric acid solution: the phosphoric acid and the solvent ratio are 1: 5...

Embodiment 3

[0062] The metal magnetic powder core powder employed in this embodiment is a ferrite molybdenum magnetine powder, wherein the nickel contains 81%, the molybdenum contains 2%, the rest is iron; the particle size of the base powder is 3 to 15 um, wherein the particle size is 5 ~ The proportion of 9 um is not less than 55%; the particle size of the nano oxide is in 50 to 500 nm, one or several of nano-tri-aluminum, silica and titanium dioxide can be used, in the present embodiment, nano oxidation The object is nano-three oxide.

[0063] The method of preparing the metal magnetic powder core in this embodiment sequentially comprises the following steps:

[0064] 1) Configure the phosphoric acid solution: the phosphoric acid and the solvent ratio are 1: 10, where the solvent in the phosphoric acid solution is ethanol;

[0065] Configure the chromic acid solution: chromic acid and solvent ratio of 1: 15, solvent in the chromic acid solution is deionized water;

[0066] 2) Magnetic powd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com