Sparkling yoghourt and production method thereof

A technology of yogurt and air bubbles, applied to milk preparations, bacteria used in food preparation, dairy products, etc., can solve the problems of poor stability and high cost of bubble yogurt, achieve low cost, improve efficiency, and avoid aggregation and stratification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

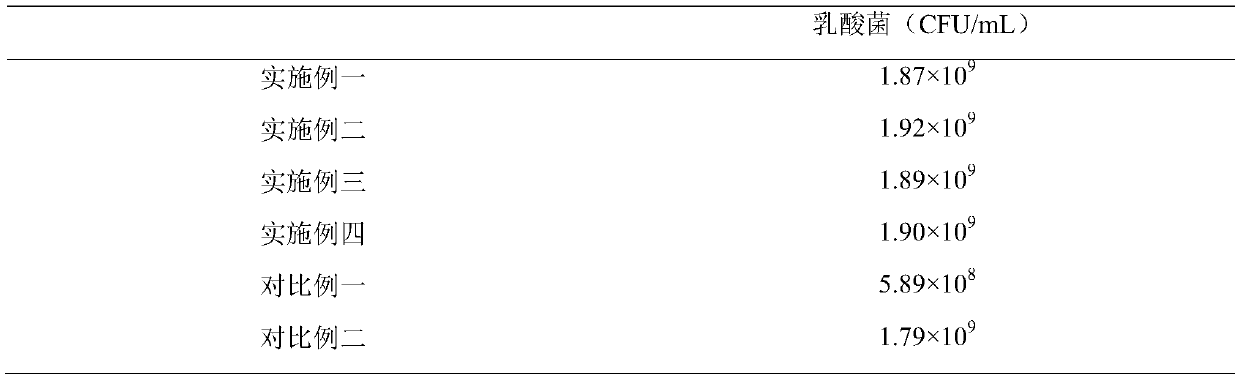

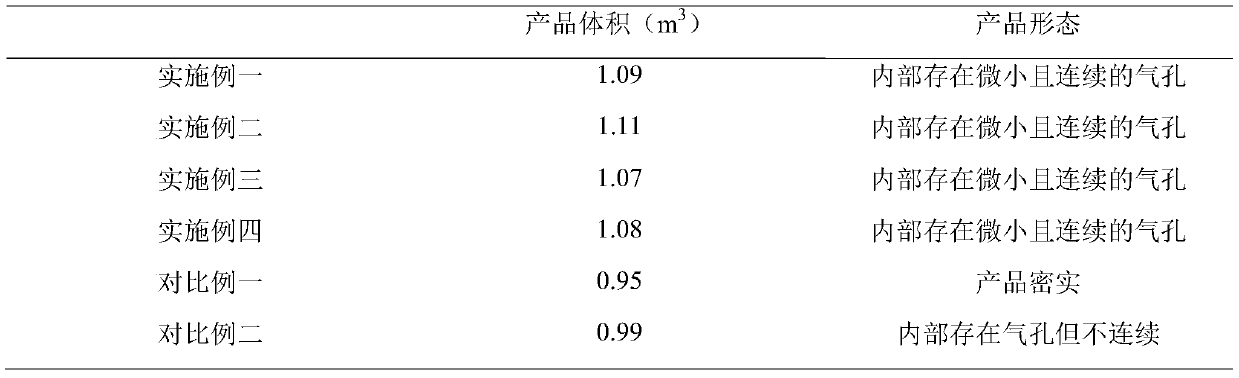

Examples

Embodiment 1

[0067] A kind of bubble yoghurt, its preparation method comprises the following steps:

[0068] (1) Weigh raw materials: 60kg of white granulated sugar, 15kg of whey protein powder, 0.7kg of egg yolk powder, 2kg of stabilizer, 0.2AU / kg of fermented strain, 0.8AU / kg of aerogenous strain, 922kg of raw milk; among them, Stabilizers are gelatin, diacetyl tartrate mono-diglycerides and pectin, and the mass ratio of gelatin, diacetyl tartrate mono-diglycerides to pectin is 6:2:2; fermentation strains include Lactobacillus bulgaricus, Streptococcus thermophilus Coccus and Lactococcus lactis subsp. lactic acid, the mass ratio of Lactobacillus bulgaricus, Streptococcus thermophilus and Lactococcus lactis subsp. The mass ratio of Lactococcus lactis subsp. lactis BNCC139461, and Leuconostoc enterococci subsp. enterica ATCC8293 to Lactococcus lactis subsp. lactis BNCC139461 was 12:14.

[0069] (2) Milk cleansing: Clean the raw milk that meets the yogurt process, so that the non-fat milk ...

Embodiment 2

[0076] A kind of bubble yoghurt, its preparation method comprises the following steps:

[0077] (1) Weigh raw materials: white granulated sugar 65kg, whey protein powder 5kg, egg yolk powder 2kg, stabilizer 4kg, fermentation strain 0.25AU / kg, gas producing strain 1.0AU / kg, raw milk 924kg; The agent is gelatin, diacetyl tartrate mono-diglyceride and pectin, and the mass ratio of gelatin, diacetyl tartrate mono-diglyceride and pectin is 6:3:1; the fermentation strain includes Lactobacillus bulgaricus, Streptococcus thermophilus and Lactococcus lactis subsp. lactic acid, the mass ratio of Lactobacillus bulgaricus, Streptococcus thermophilus and Lactococcus lactis subsp. The mass ratio of Lactococcus subsp. lactis BNCC139461, and Leuconostoc enterococci subsp. enterica ATCC8293 to Lactococcus lactis subsp. lactis BNCC139461 was 14:12.

[0078] (2) Milk cleansing: Clean the raw milk that meets the yogurt process, so that the non-fat milk solids are not less than 8.5%, and the raw ...

Embodiment 3

[0085] A kind of bubble yoghurt, its preparation method comprises the following steps:

[0086] (1) Weigh raw materials: 50kg of white granulated sugar, 20kg of whey protein powder, 1kg of egg yolk powder, 6kg of stabilizer, 0.2AU / kg of fermentation bacteria, 0.6AU / kg of gas producing bacteria, 923kg of raw milk; The agent is gelatin, diacetyl tartrate mono-diglyceride and pectin, and the mass ratio of gelatin, diacetyl tartrate mono-diglyceride and pectin is 5:4:1; the fermentation strain includes Lactobacillus bulgaricus, Streptococcus thermophilus and Lactococcus lactis subsp. lactic acid, the mass ratio of Lactobacillus bulgaricus, Streptococcus thermophilus and Lactococcus lactis subsp. The mass ratio of Lactococcus subsp. lactis BNCC139461, and Leuconostoc enterococci subsp. enterica ATCC8293 to Lactococcus lactis subsp. lactis BNCC139461 was 10:15.

[0087] (2) Milk cleansing: Clean the raw milk that meets the yogurt process, so that the non-fat milk solids are not les...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com