Liquid foundation and preparation method thereof

A technology of liquid foundation and aqueous solution, which is applied in the fields of pharmaceutical formulations, toiletry preparations, cosmetic preparations, etc. It can solve the problems that affect the speed and quality of makeup application, the smoothness of liquid foundation is not enough, and it is not easy to apply evenly. Achieve excellent extensibility and smoothness, low consistency, light and thin texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8

[0045] Embodiment 1-8: a liquid foundation, with 100kg as the total weight, the components included and the corresponding quality are shown in Table 1, and prepared by the following steps:

[0046] S1: Weigh and mix quaternary ammonium salt-18 bentonite, emollient and cetyl polydimethylsiloxane, and homogenize for 5 minutes at a stirring speed of 6000 r / min; Homogenize under stirring speed for 5min; then add polyethylene and bismuth oxychloride, heat to 80°C and keep warm to obtain mixture A;

[0047] S2: Weigh and mix the raw materials of group A, heat to 80°C, and stir for 2 hours at a stirring speed of 800 r / min to obtain mixture B;

[0048] S3: Add mixture A to mixture B, and stir for 10 s under the condition of a stirring speed of 800 r / min to obtain a foundation liquid.

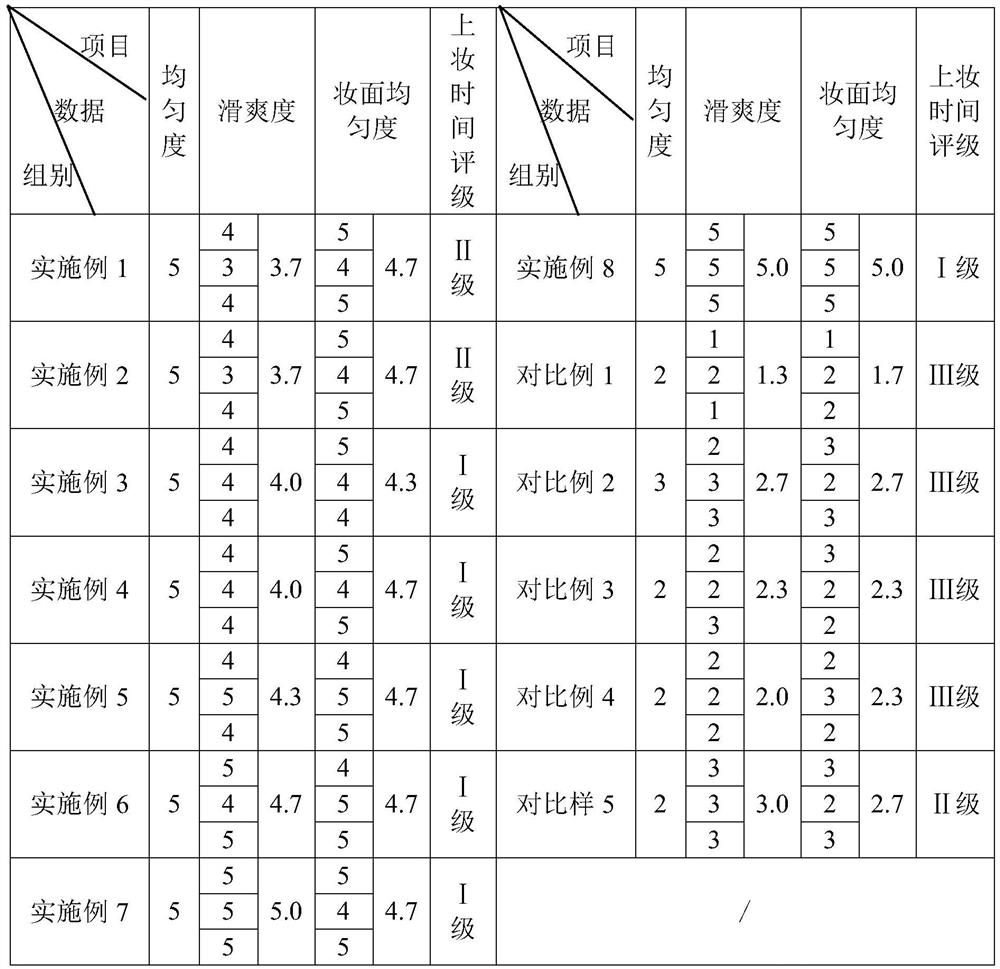

[0049] Table 1 embodiment 1-8 components and corresponding mass (kg)

[0050]

[0051] In Example 1-2, the emollient was mineral oil, and in Example 3-8, the emollient was coco-caprylate / caprate. ...

Embodiment 9

[0052] Embodiment 9: a kind of preparation method of liquid foundation, comprises the following steps:

[0053]S1: Weigh and mix the quaternary ammonium salt-18 bentonite, emollient and cetyl polydimethylsiloxane, and homogenize for 5 minutes at a stirring speed of 6000r / min; Homogenize under stirring speed for 5min; then add polyethylene and bismuth oxychloride, heat to 80°C and keep warm to obtain mixture A;

[0054] S2: Weigh and mix the raw materials of group A, heat to 80°C, and stir for 2 hours at a stirring speed of 500 r / min to obtain mixture B;

[0055] S3: Add mixture A to mixture B, and stir for 10 s under the condition of a stirring speed of 500 r / min to obtain a foundation liquid.

Embodiment 10

[0056] Embodiment 10: a preparation method of liquid foundation, the difference from Embodiment 10 is that in this embodiment, the stirring speed in step S2 is 900 r / min, the stirring speed in step S3 is 900 r / min, and the stirring time is 5s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com