A nanofiber loaded metal organic framework air purification material and preparation method thereof

An air purification material, organic framework technology, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve problems such as limiting practical applications, and achieve the effects of large porosity, high specific surface area, and good filtration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

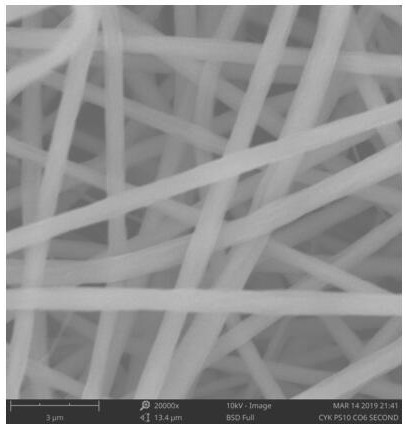

[0025] The preparation method of the nanofiber-loaded metal-organic framework air purification material of this embodiment is as follows:

[0026] (1) Dissolve cobalt acetate and polystyrene in DMF at a mass ratio of 1:3, and stir at 60°C for 8 hours to obtain 12% PS, 4% Co(AC) 2 spinning solution;

[0027] (2) Transfer the electrospinning solution obtained in step (1) to a syringe for electrospinning. The electrospinning positive voltage is 18KV, the negative voltage is 1KV, the flow rate is 0.08ml / h, and the electrospinning receiving distance is 15cm, the receiving speed is 150mm / min, and non-woven fabric is used as the receiving substrate;

[0028] (3) Soak the nanofiber membrane prepared in step (2) in 2-methylimidazole / ethanol solution, the soaking concentration is 4g-2MI / 100ml absolute ethanol, and the soaking time is 24h, and ZIF-67@PS is obtained -1 material.

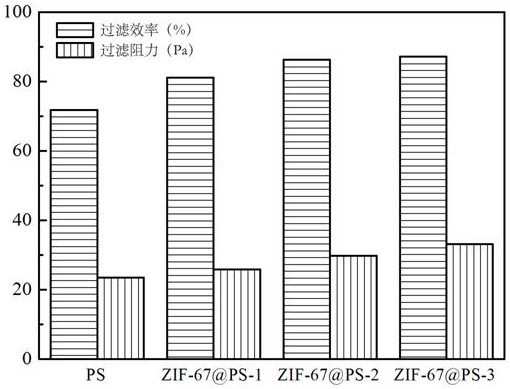

[0029] The ZIF-67@PS-1 material prepared in step (3) was cut into 20cm×20cm, and the filtration performanc...

Embodiment 2

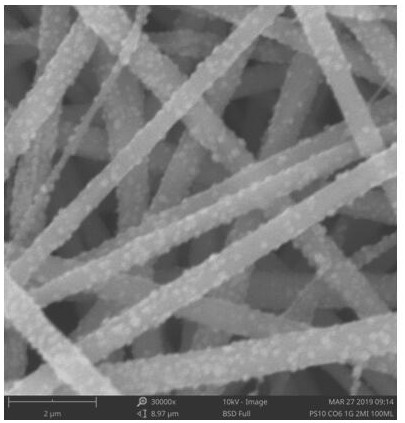

[0031] The preparation method of the nanofiber-loaded metal-organic framework air purification material of this embodiment is as follows:

[0032] (1) Dissolve cobalt acetate and polystyrene in DMF at a mass ratio of 1:2, and stir at 60°C for 12 hours to obtain 12% PS, 6% Co(AC) 2 spinning solution;

[0033] (2) Transfer the electrospinning solution obtained in step (1) to a syringe for electrospinning. The electrospinning positive voltage is 20KV, the negative voltage is 1KV, the flow rate is 0.08ml / h, and the electrospinning receiving distance is 16cm, the receiving speed is 140mm / min, using non-woven fabric as the receiving substrate;

[0034] (3) Soak the nanofiber membrane prepared in step (2) in 2-methylimidazole / ethanol solution, the soaking concentration is 3g-2MI / 100ml absolute ethanol, and the soaking time is 24h, and ZIF-67@PS is obtained -2 materials.

[0035] The ZIF-67@PS-2 material prepared in step (3) was cut into 20cm×20cm, and the filtration performance an...

Embodiment 3

[0037] The preparation method of the nanofiber-loaded metal-organic framework air purification material of this embodiment is as follows:

[0038] (1) Dissolve cobalt acetate and polystyrene in DMF at a mass ratio of 2:3, and stir at 60°C for 10 hours to obtain 12% PS, 8% Co(AC) 2 spinning solution;

[0039] (2) Transfer the electrospinning solution obtained in step (1) to a syringe for electrospinning. The electrospinning positive voltage is 22KV, the negative voltage is 1KV, the flow rate is 0.1ml / h, and the electrospinning receiving distance is 18cm, the receiving speed is 150mm / min, and non-woven fabric is used as the receiving substrate;

[0040] (3) Soak the nanofiber membrane prepared in step (2) in 2-methylimidazole / ethanol solution, the soaking concentration is 2g-2MI / 100ml absolute ethanol, and the soaking time is 24h, and ZIF-67@PS is obtained -3 materials.

[0041] The ZIF-67@PS-3 material prepared in step (3) was cut into 20cm×20cm, and the filtration performan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com