A robotic corrugated plate automatic welding method based on laser seam tracking

An automatic welding and robot technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of non-adjustable welding torch angle, precise control, and inability to realize welding line, etc., to reduce parameter configuration, high degree of automation, guarantee The effect of welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The present invention is a robot automatic welding method for corrugated plates based on laser seam tracking, and its specific operation method is as follows:

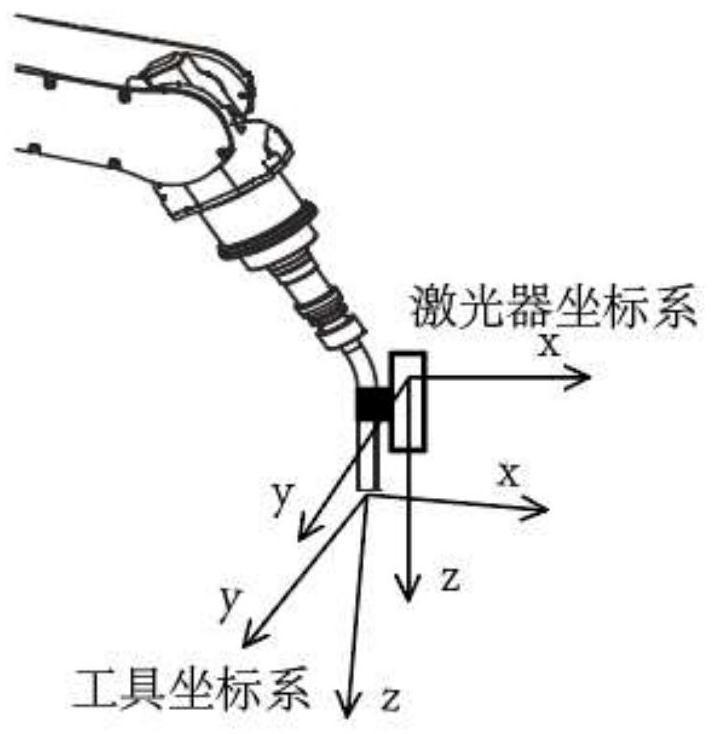

[0042] (1) Realize a calibration algorithm of laser seam tracker, which is used to calibrate the coordinate system of laser seam tracker. Afterwards, the x, y, and z offset values measured by the laser can be directly converted into the target point of the robot;

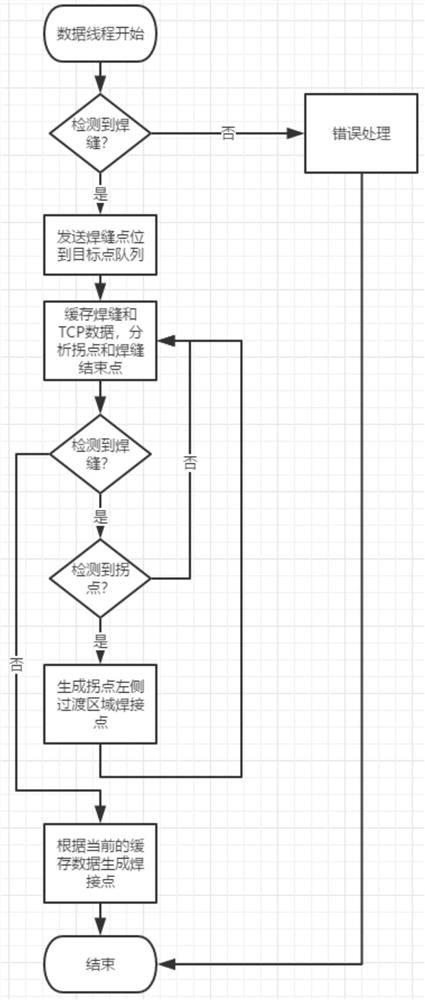

[0043] (2) Define a weld data buffer module, which is used to temporarily store the feedback data of the laser (including the x / y / z offset of the weld, and the corresponding robot TCP position), and call the visual processing module to preprocess the weld data . In actual use, since the laser seam tracker is front-mounted, the laser line is 20cm away from the center point of the tool (TCP, welding wire position). Ensure that at least one corrugated board module can be buffered in the buffer (that is, a complete cycle);

[0044] (3) Realize a visu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com