A production process of multi-strand welding wire for marine engineering

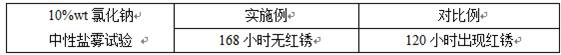

A technology of multi-strand stranded welding wire and production process, applied in welding equipment, manufacturing tools, welding medium and other directions, can solve problems such as difficulty in ensuring surface quality and cleanliness, complex structure of stranded welding wire, and no corrosion resistance. , to achieve the effect of improving corrosion resistance in marine environment, improving weld stability, and high welding process matching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

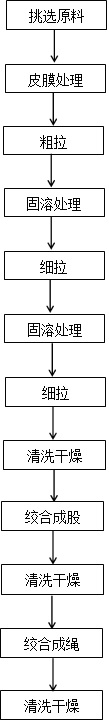

Method used

Image

Examples

Embodiment

[0032] S1: Select φ5.5mm stainless steel wire rod, its chemical composition is: C≤0.02%, Si≤0.65%, Mn: 1.0%-2.5%, P≤0.03%, S≤0.03%, Ni: 12.00%-14.00 %, Cr: 24.00%-25.00%, Cu≤0.75%, Mo≤0.75%, and the balance is Fe.

[0033] S2: Film treatment, immerse the φ5.5mm stainless steel wire rod selected in S1 in the film treatment solution at 80°C for 30 minutes. The film treatment solution is an aqueous solution of potassium sulfate and calcium sulfate with a concentration of 20wt%. After soaking, take it out and put it in the warm air Dry in the furnace, the drying temperature is 230°C, the drying time is 100min, and the surface of the steel wire is dry before use.

[0034] S3: Rough drawing, the φ5.5mm stainless steel wire rod treated with the S2 film is drawn through 7 passes at a speed of 250m / min through the pay-off frame, and calcium-based lubricant powder (stearic acid) is used in all passes. Calcium and potassium sulfate mixture), the drawing specifications of each pass are 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com