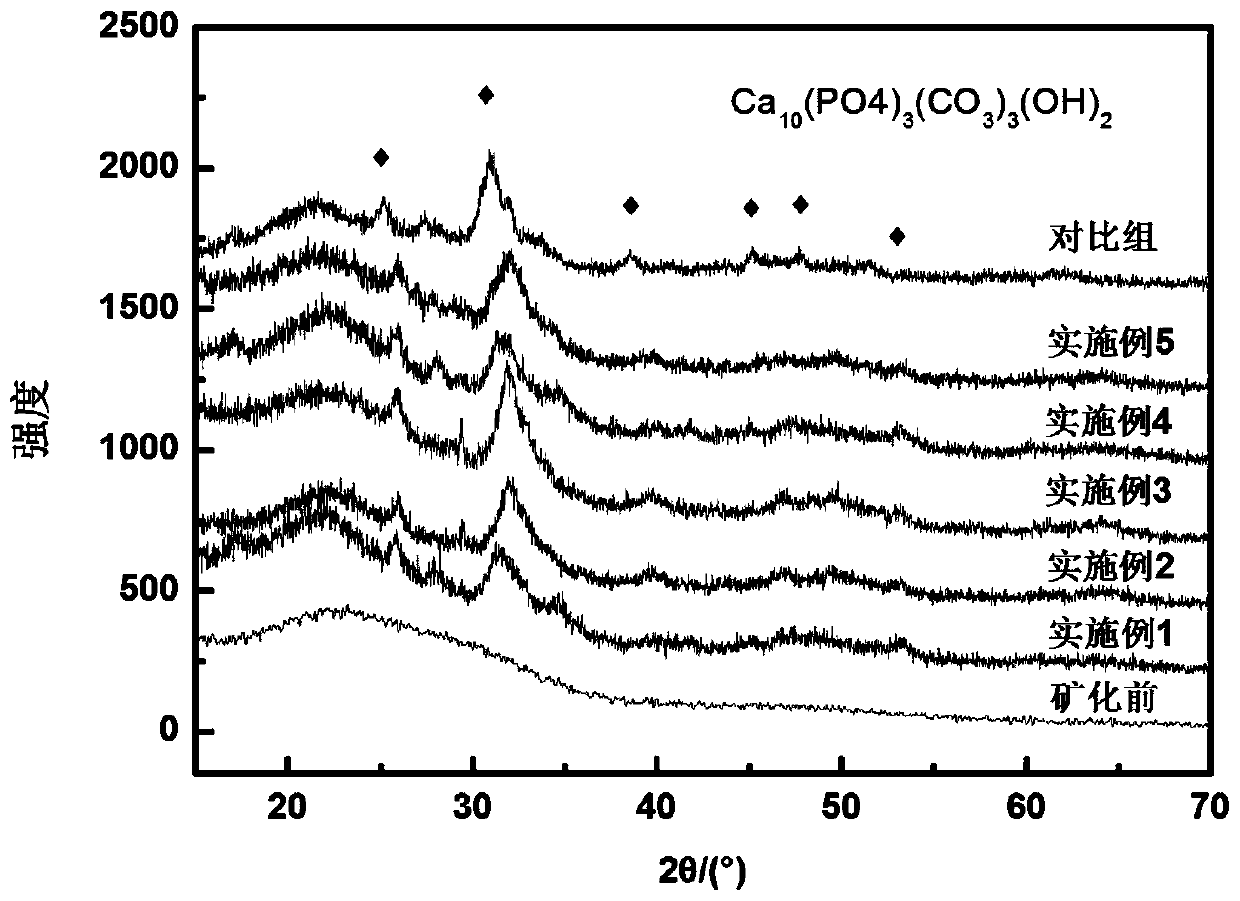

Bioactive silicon regenerative medical material and preparation method thereof

A technology for bioactive silicon and medical materials, applied in the field of bioactive silicon regenerative medical materials and their preparation, can solve the problems of increasing the alcohol solvent recovery system, the influence of material uniformity, equipment corrosion, etc., and achieve the aging and drying process. The effect of short time, simple operation method and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] In a second aspect, the present invention provides a method for preparing the biosilicon material of the above-mentioned first aspect, the method comprising:

[0037] Step 1. Preparation of the total mixed solution: add silica sol, surfactant, phosphate esters, and calcium-containing salts into the reactor to obtain the total mixed solution. Specifically include:

[0038] Sub-step 1: Add silica sol and surfactant into the reactor, then stir evenly, measure and record the pH value, and obtain mixed solution A.

[0039] The above-mentioned determination of the pH value is to clarify which pH value regulator is selected in the following steps, corresponding to the pH value adjustment step. Sub-step 2: Add phosphoric acid esters into the reactor under stirring, heat to 40-50° C. and stir for 20-40 minutes, preferably 30 minutes, to obtain mixed solution B. If the above-mentioned heating temperature is too low, it is not conducive to the reaction, but if the temperature ex...

Embodiment 1

[0050] A formula for synthesizing bioactive silicon regenerative medical materials using silica sol as a silicon precursor, comprising the following molar fractions:

[0051]

[0052] The preparation method of the bioactive silicon regenerative medicine material formula of the present embodiment is as follows:

[0053] (1) First, add ZS-30 silica sol into the reactor, add surfactant and stir evenly, the pH is determined to be 7.20, and recorded.

[0054] (2) Then, the phosphoric acid esters were added into the reactor under stirring, heated to 45° C. and stirred for 30 minutes.

[0055] (3) Then, calcium-containing salts are added into the reactor in the form of a saturated solution and stirred for 60 minutes.

[0056] (4) Then, the pH value of the reaction product was adjusted to 5.0 with a pH regulator, and aged at 40° C. for 12 hours, the solution completely turned into a uniform gel state.

[0057] (5) Then, the gel was broken into small pieces and baked at 100° C. fo...

Embodiment 2

[0066] A formula for synthesizing bioactive silicon regenerative medical materials using silica sol as a silicon precursor, comprising the following molar fractions:

[0067]

[0068] The preparation method of the bioactive silicon regenerative medicine material formula of the present embodiment is as follows:

[0069] (1) First, add ZS-30 silica sol into the reactor, add surfactant and stir evenly, the pH value is determined to be 7.21 and recorded.

[0070] (2) Then, the phosphoric acid esters were added into the reactor under stirring, heated to 45° C. and stirred for 30 minutes.

[0071] (3) Then, calcium-containing salts are added into the reactor in the form of a saturated solution and stirred for 60 minutes.

[0072] (4) Then, adjust the pH value of the reaction product to 5.0 with a pH regulator, and age at 40° C. for 12 hours, and the solution completely becomes a uniform gel state;

[0073] (5) Then, the gel was broken into small pieces and baked at 100° C. for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com