A kind of cement slurry system and preparation method thereof

A technology of cement slurry and system, applied in the field of cement slurry system and its preparation, can solve the problems that the cement annulus cannot maintain elastic properties, lose the effect of sealing the annulus, and be damaged, so as to reduce the risk of pressure in the annulus and effectively interlayer The effect of sealing and ensuring sealing ability

Active Publication Date: 2022-06-03

CHINA PETROLEUM & CHEM CORP +1

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The basic properties of the high-temperature-resistant and high-density cementing slurry currently used can meet the construction requirements, but considering the requirements of the shale gas target layer cementing construction, the existing cement slurry system does not add enough elastic materials, and the cement sheath cannot maintain a good Elastic performance, easy to be damaged in the later stage of large-scale fracturing construction, and lose the effect of sealing the annulus

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

preparation example Construction

[0033] Unless otherwise specified, the weighting agent used in each embodiment of the present invention and the comparative example is the iron ore powder with a particle size of 120 objects.

Embodiment 1

Embodiment 2

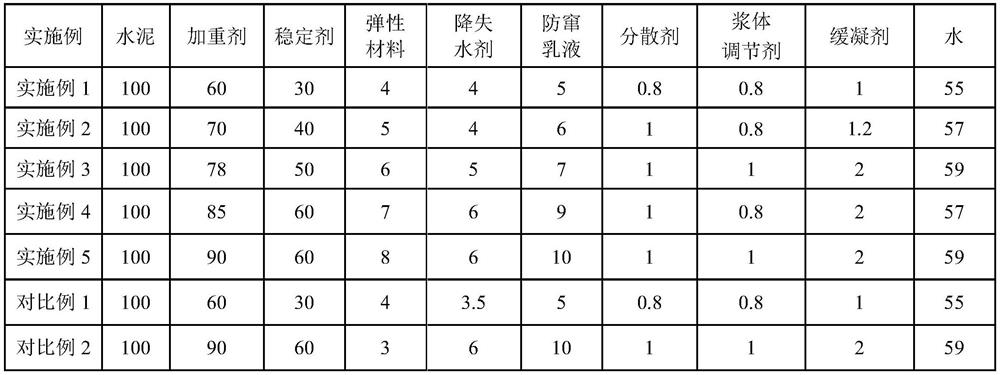

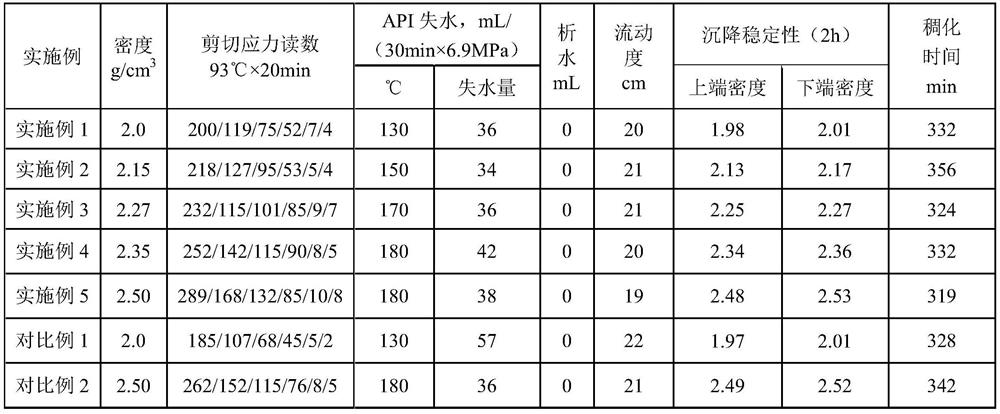

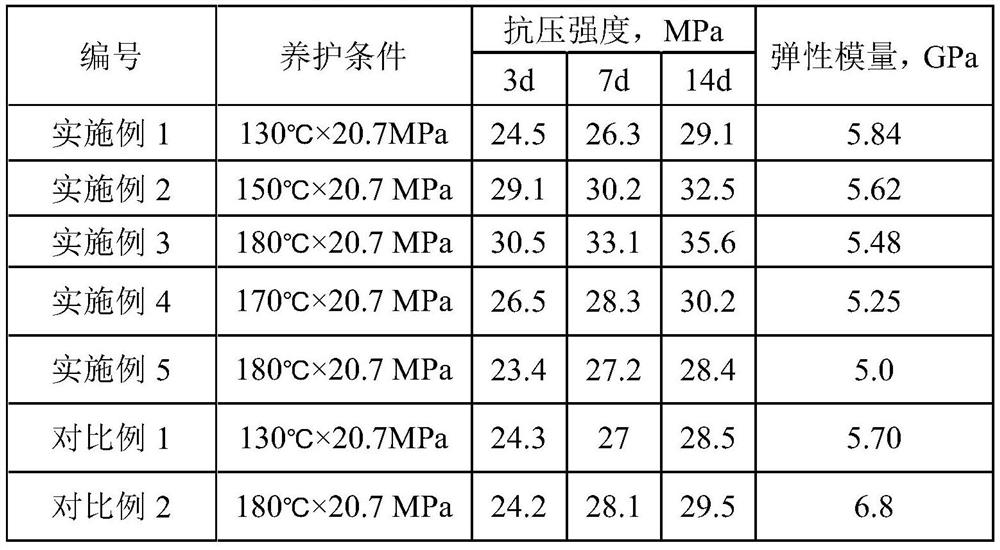

[0049] The consumption of each component is shown in Table 1.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Login to View More

Abstract

The invention provides a cement slurry system and a preparation method thereof. The raw materials of the cement slurry system include G grade oil well cement, high temperature resistant elastic material, high temperature resistant fluid loss reducer, high temperature resistant inorganic anti-channeling emulsion, weighting agent, high temperature strength stabilizer, dispersant, slurry regulator, retarder agent and water. The cement sheath formed by using this cement slurry system in the high temperature and high pressure environment and the later large-scale fracturing construction process has good elastic properties, can maintain its integrity for a long time, effectively guarantees the interlayer seal, and reduces the risk of shale gas wells. Risk of annular pressure.

Description

A kind of cement slurry system and preparation method thereof technical field The present invention provides a kind of cement slurry system and preparation method thereof, particularly suitable for cementing of deep shale gas wells. High temperature resistant high density cement slurry system. Background technique [0002] In recent years, the exploration and development of shale gas has continued to deepen, and the technology of deep shale gas exploration and development has become a research focus. [0003] Deep shale gas generally has geological characteristics such as high temperature and high density. technology is a huge challenge. The basic performance of the high temperature resistance, high density cementing slurry currently used can meet the construction requirements, but considering the The requirements for cementing construction of rock and gas target layers, the existing cement slurry system does not add enough elastic materials, and the cement sheath cann...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C04B28/00C09K8/467C09K8/48

CPCC04B28/00C09K8/467C09K8/48C09K2208/10C04B2201/50C04B2201/20C04B2111/00146C04B18/142C04B18/146C04B18/22C04B22/02C04B20/0008C04B24/16C04B14/06C04B24/30C04B12/04C04B22/002C04B2103/22Y02W30/91

Inventor 陶谦杜晓雨谭春勤刘飞陆沛青张林海

Owner CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com