Carbon quantum dot with ultrahigh fluorescence quantum yield, carbon quantum dot/PVA fluorescent film and preparation method and application thereof

A technology of fluorescence quantum yield and carbon quantum dots, applied in chemical instruments and methods, luminescent materials, electrical components, etc., can solve problems such as poor water solubility, complicated preparation methods, and complicated operations, and achieve the effect of good water dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

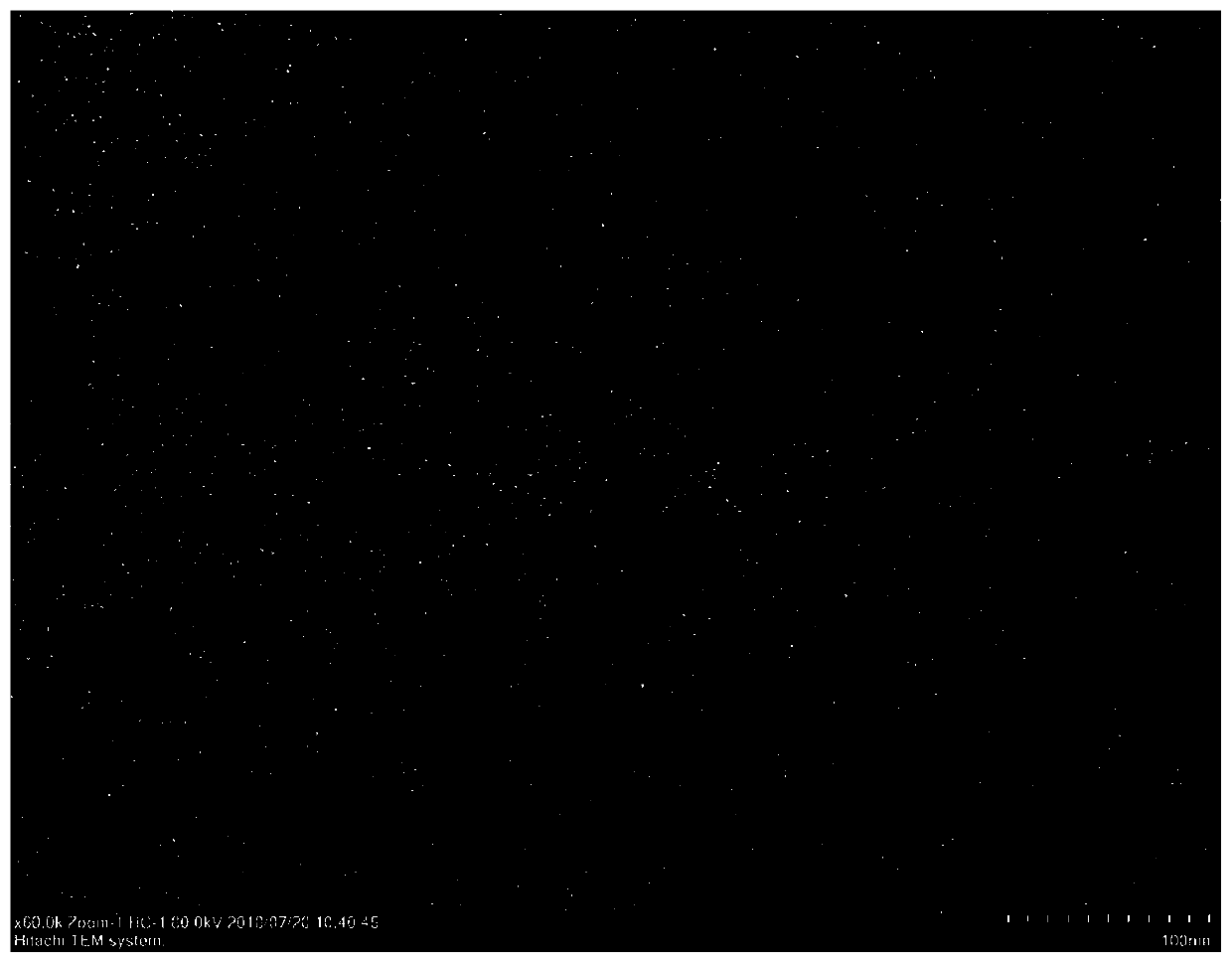

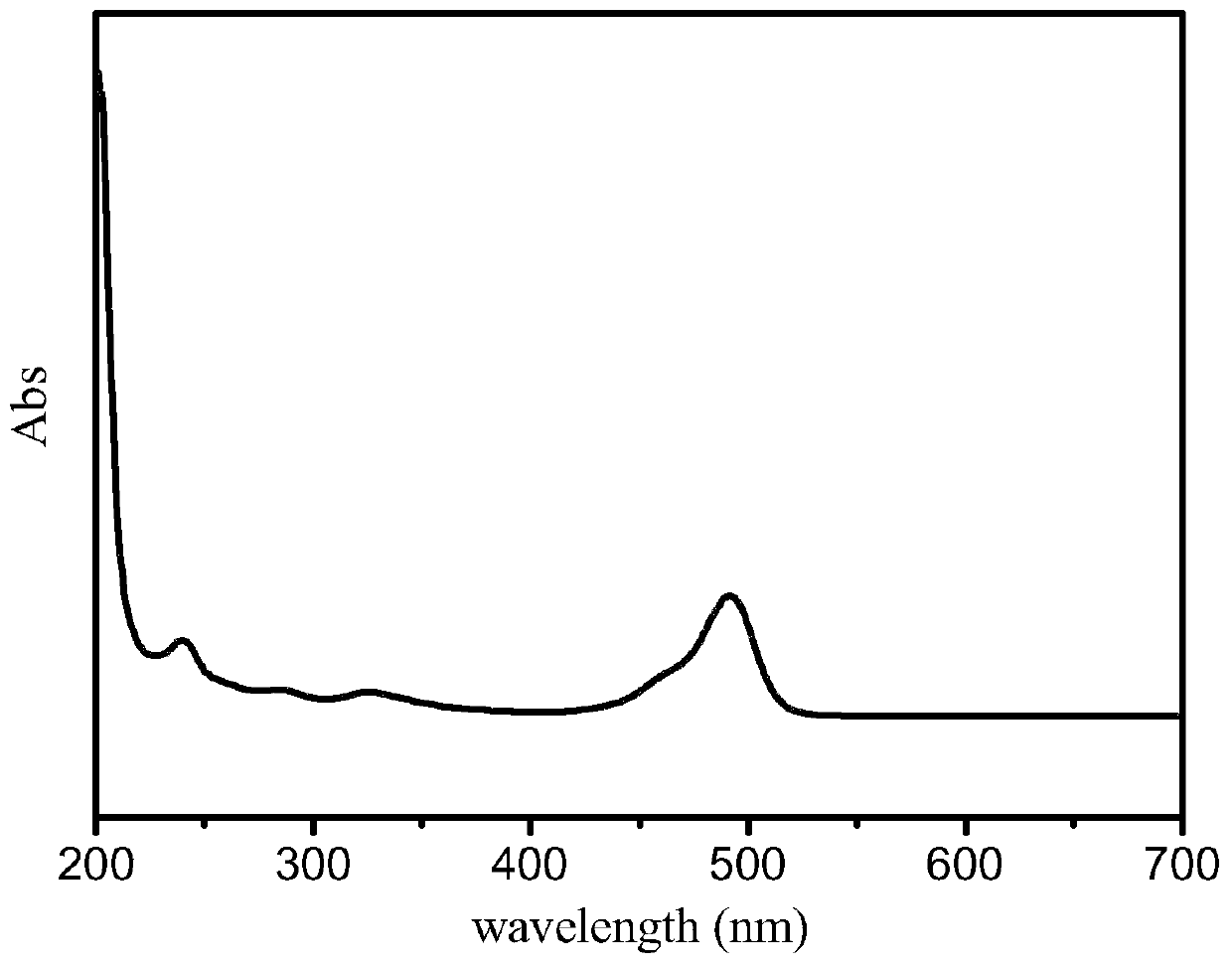

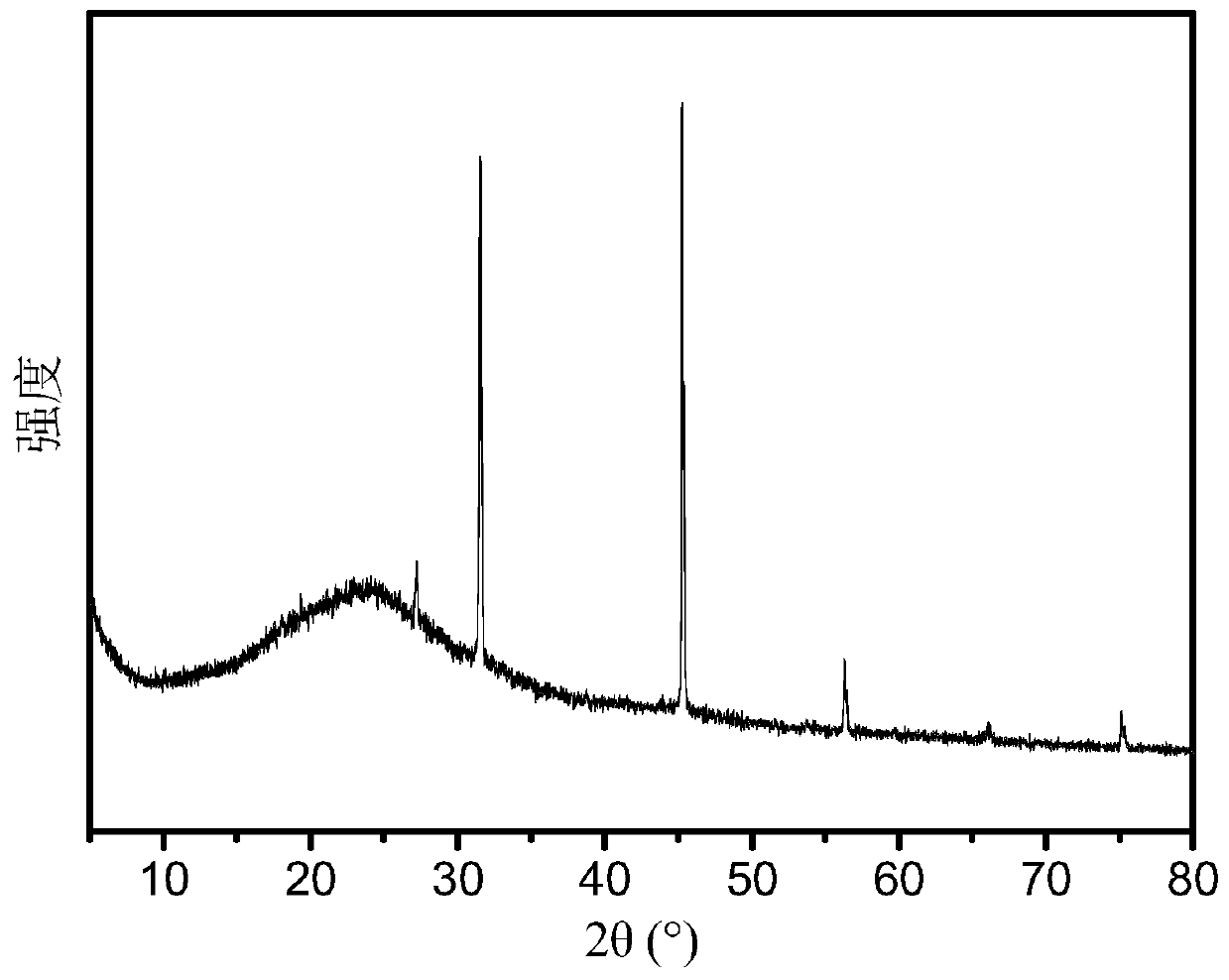

[0033] Embodiment 1 The preparation method of the carbon quantum dots of ultra-high fluorescence quantum yield provided in this embodiment comprises the following steps:

[0034] (1) First, pipette 1mL of prepared 10M sodium hydroxide solution and 1ml of polyethylene glycol 400, dilute the mixed solution to 15mL with ultrapure water, then weigh 30mg of rhodamine B and dissolve in the above mixed solution After stirring evenly, it was transferred to a polytetrafluoroethylene reactor, put into an oven, heated to 180°C and continued to react for 12 hours.

[0035] (2) Cool to room temperature, pour out the solution in the reaction kettle, adjust the solution to neutrality with hydrochloric acid, then divide the solution into 1000Da dialysis bags, and frequently change the water and dialyze for 72 hours to remove impurities.

[0036] (3) After the dialysis was completed, the solution was collected, concentrated by rotary evaporation at 65°C, and then freeze-dried to obtain carbon ...

Embodiment 2

[0049] Embodiment 2 The preparation method of the carbon quantum dots with high fluorescence quantum yield provided in this embodiment comprises the following steps:

[0050] (1) First, pipette 1mL of prepared 10M sodium hydroxide solution and 1ml of polyethylene glycol 400, dilute the mixed solution to 15mL with ultrapure water, then weigh 28mg of rhodamine B and dissolve in the above mixed solution After stirring evenly, it was transferred to a polytetrafluoroethylene reactor, put into an oven, heated to 200°C and continued to react for 8 hours.

[0051] (2) Cool to room temperature, pour out the solution in the reaction kettle, adjust the solution to neutrality with hydrochloric acid, then divide the solution into 800Da dialysis bags, and frequently change the water and dialyze for 92 hours to remove impurities.

[0052] (3) After the dialysis was completed, the solution was collected, concentrated by rotary evaporation at 65°C, and then freeze-dried to obtain carbon quantum ...

Embodiment 3

[0053] Embodiment 3, the preparation method of the carbon quantum dot of ultra-high fluorescence quantum yield provided by the present embodiment, comprises the following steps:

[0054] (1) First, pipette 1mL of prepared 10M sodium hydroxide solution and 1ml of polyethylene glycol 400, dilute the mixed solution to 14mL with ultrapure water, then weigh 20mg of rhodamine B and dissolve in the above mixed solution After stirring evenly, it was transferred to a polytetrafluoroethylene reactor, put into an oven, heated to 190°C and continued to react for 10 hours.

[0055] (2) Cool to room temperature, pour out the solution in the reaction kettle, adjust the solution to neutrality with hydrochloric acid, then divide the solution into 900Da dialysis bags, and often change the water and dialyze for 80 hours to remove impurities.

[0056] (3) After the dialysis was completed, the solution was collected, concentrated by rotary evaporation at 65°C, and then freeze-dried to obtain carbo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com