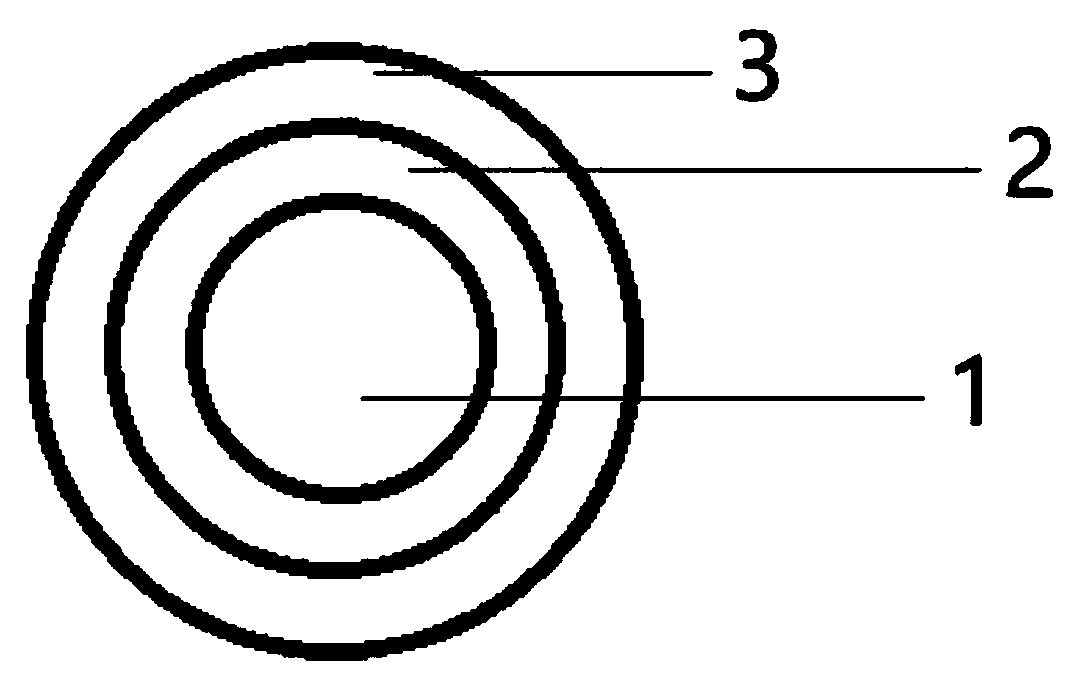

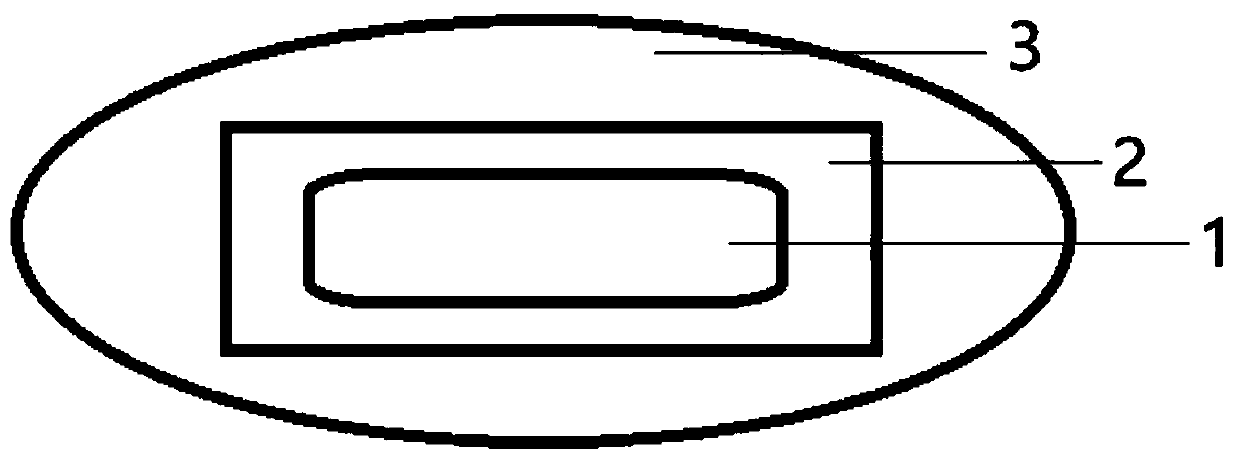

Multi-layer structure composite biomass granular fuel with stable heat release and preparation method thereof

A biomass particle, multi-layer structure technology, applied in the direction of biofuel, waste fuel, fuel, etc., can solve the problems of unstable heat release, fast burning speed, burning time period, etc., to increase the scope of application, slow burning, release heat stabilized effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

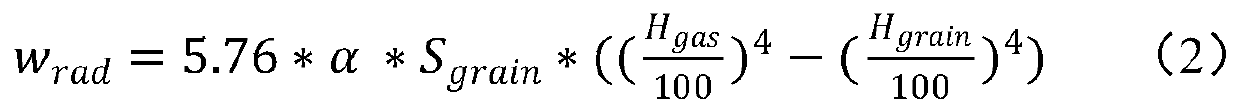

Method used

Image

Examples

preparation example 1

[0062] The preparation of preparation example 1 animal bone meal:

[0063] Remove the impurities on the surface of the pig bones, mash them, place them in a tube furnace, and treat them at 800-1000°C for 45 minutes under the protection of nitrogen, and then mill them in a ball mill for 6 hours. The particle size is 0.01-1mm.

preparation example 2

[0064] The preparation of preparation example 2 basic fuels:

[0065] Basic fuel A: Wheat straw and rice straw (dry) are crushed to a particle size of 0.5-5 mm, and mixed at a mass ratio of 1:1;

[0066] Basic fuel B: Sawdust, corncobs, peanut husks, rice husks, and camellia husks are crushed to a particle size of 0.5-5mm, and mixed in equal mass proportions.

preparation example 3

[0067] The preparation of other raw materials of preparation example 3:

[0068] Coconut shell powder, bentonite, fermented, decomposed and dried rapeseed cake, and fly ash are respectively prepared to a particle size of 0.5-5 mm for use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com