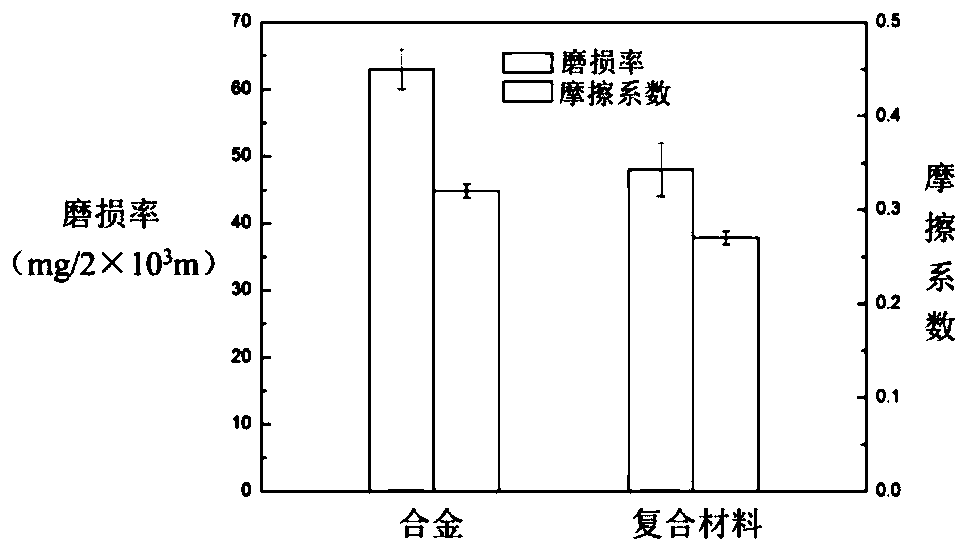

Nanometer SiC particle-reinforced magnesium-based composite board and preparation method thereof

A particle-reinforced, composite plate technology, applied in the field of magnesium-based composite material preparation, can solve problems such as low wear resistance, low strength and toughness, and achieve the effects of reducing casting defects, good plasticity, and improved strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The technique of preparing the preparation method of the nano-SiC particle reinforced magnesium-based composite plate in this example mode is carried out in the following steps:

[0033] Step 1. Put the magnesium alloy ingot into the stainless steel mold placed in the resistance furnace, and raise the temperature of the resistance furnace to the melting temperature of the magnesium alloy, wait until it is completely melted, and then cool the temperature of the melt to the semi-solid stirring temperature ; The purity of Mg is not less than 99.98wt.%, the purity of Al is not less than 99.96wt.%, and the purity of Zn is not less than 99.95wt.%. It is prepared into Mg-2.7Al-0.8Zn;

[0034] Step 2. Slowly introduce the stirring paddle into the semi-solid melt, and start the electric stirring device. When the melt surface generates a vortex with a certain size and depth, quickly and evenly inject the preheated nano-SiC particles, and then follow a certain stirring Stirring at...

Embodiment 2

[0049] The process of preparing nano-SiC particle reinforced AZ31B magnesium-based composite material in this example is carried out in the following steps:

[0050] Step 1. Put the AZ31B magnesium alloy ingot into the stainless steel mold placed in the resistance furnace, and raise the temperature of the resistance furnace to 720±5°C. After the AZ31B magnesium alloy ingot is completely melted, lower its temperature to a semi-solid temperature of 615°C ±15°C, a semi-solid solution is obtained;

[0051] Step 2. Insert the stirring paddle into the semi-solid melt obtained in step 1, start the stirring device, and start to rotate the stirring paddle. When a 2cm deep vortex is generated at the liquid surface of the melt, preheat the nano-SiC particles at 660±10°C Introduce into the melt, and stir the mixture composed of nano-SiC particles and semi-solid melt to obtain a semi-solid mixture with uniform distribution of nano-SiC particles;

[0052] Step 3. Raise the temperature of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com