Low-smoke halogen-free fireproof cable

A fire-resistant cable and cable core technology, applied in the direction of insulating cables, cables, circuits, etc., can solve the problems of environmental secondary pollution, improve fire resistance and corrosion resistance, improve elasticity and compression resistance, improve mechanical properties and The effect of antibacterial activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

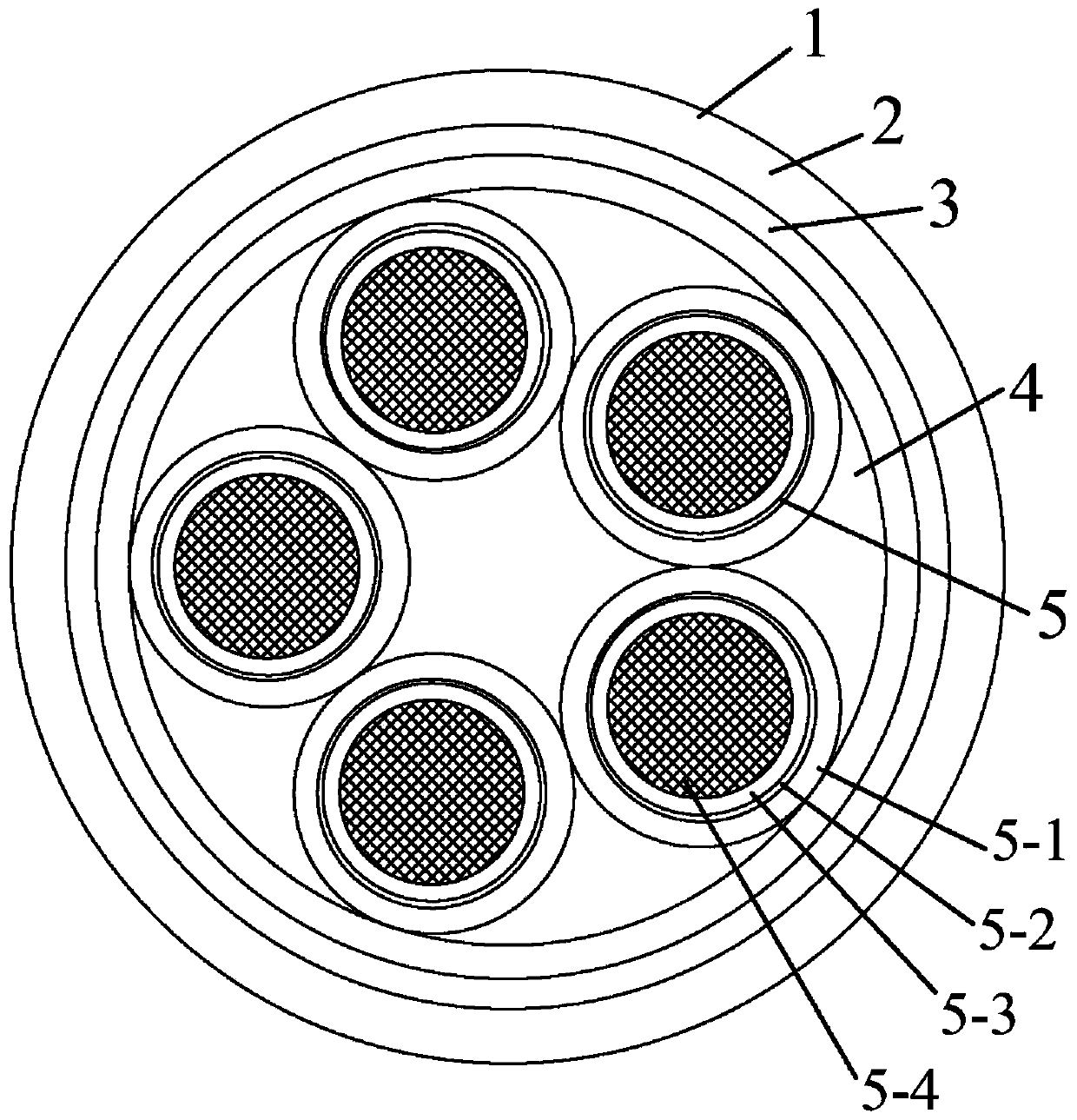

[0042] Such as figure 1 As shown, it is a low-smoke, halogen-free, fire-resistant cable provided in this embodiment, which includes a low-smoke, halogen-free, flame-retardant polyolefin layer 1, a non-woven fabric tape 2, a glass fiber tape 3, and an insulating filling layer 4 from outside to inside. , five cable core units 5; each cable core unit 5 includes ceramic polyolefin insulation layer 5-1, mica tape insulation layer 5-2, phenylenediamine modified graphene oxide layer 5-3 and Conductor 5-4. Wherein, the mica tape insulating layer 5-2 is composed of a layer of 0.10mm mica tape 5-2, the overlap rate of the glass fiber tape 3 to the insulating filling layer 4 is 10%, and the insulating filling layer 4 is an inorganic rope.

[0043] Wherein, the preparation method of the low-smoke halogen-free flame-retardant polyolefin layer comprises the following steps:

[0044] 1) Stir and mix 5 parts by weight of BASF flame retardant, 30 parts of 1,3,5-triazine, 10 parts of pentaery...

Embodiment 2

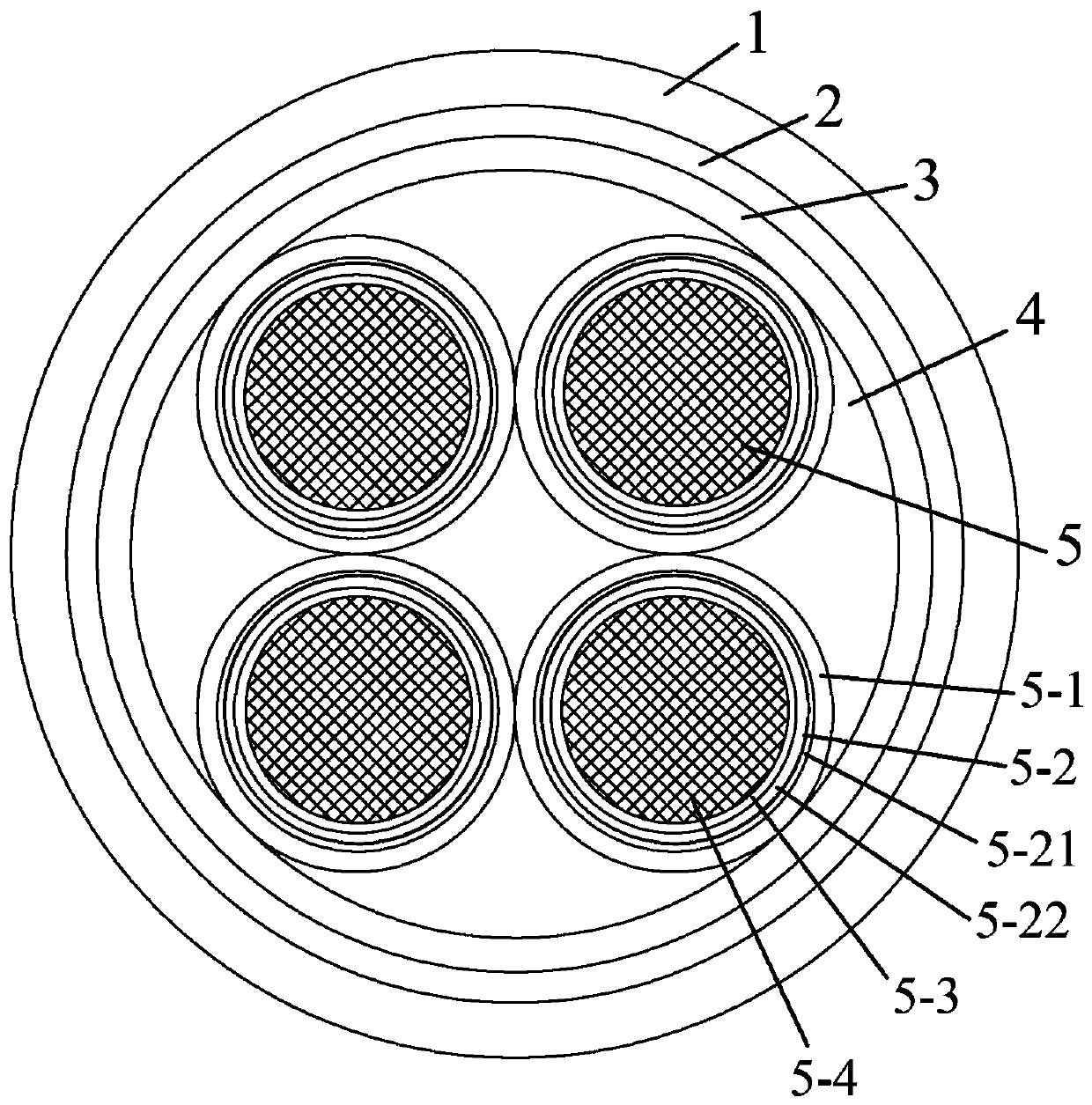

[0054] Such as figure 2 As shown, it is a low-smoke, halogen-free, fire-resistant cable provided in this embodiment, which includes a low-smoke, halogen-free, flame-retardant polyolefin layer 1, a non-woven fabric tape 2, a glass fiber tape 3, and an insulating filling layer 4 from outside to inside. , four cable core units 5; each cable core unit 5 includes ceramic polyolefin insulation layer 5-1, mica tape insulation layer 5-2, phenylenediamine modified graphene oxide layer 5-3 and Conductor 5-4. Wherein, the mica tape insulation layer 5-2 is made of two layers of mica tape——mica tape 5-21 and mica tape 5-22, the thickness of the two layers of mica tape is 0.12mm and 0.15mm respectively, and the glass fiber tape has an effect on the insulating filling layer. The covering rate is 12%, and the insulating filling layer is glass fiber rope.

[0055] Wherein, the preparation method of the low-smoke halogen-free flame-retardant polyolefin layer comprises the following steps:

...

Embodiment 3

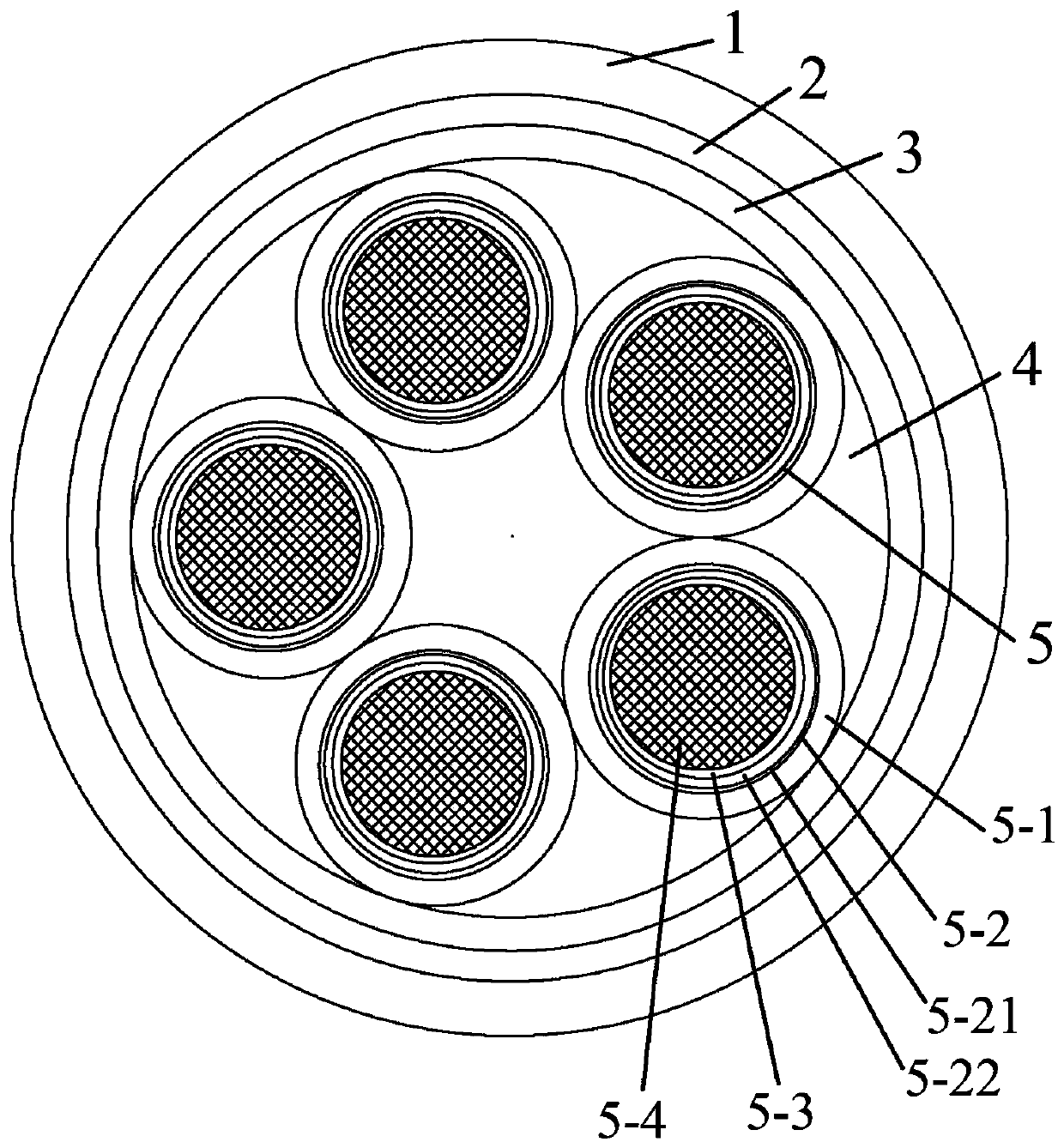

[0066] Such as image 3 As shown, it is a low-smoke, halogen-free, fire-resistant cable provided in this embodiment, which includes a low-smoke, halogen-free, flame-retardant polyolefin layer 1, a non-woven fabric tape 2, a glass fiber tape 3, and an insulating filling layer 4 from outside to inside. , five cable core units 5; each cable core unit 5 includes ceramic polyolefin insulation layer 5-1, mica tape insulation layer 5-2, phenylenediamine modified graphene oxide layer 5-3 and Conductor 5-4. Wherein, the mica tape insulating layer 5-2 is made of two layers of mica tape—mica tape 5-21 and mica tape 5-22, the thickness of the two layers of mica tape is 0.20mm respectively, and the glass fiber tape 3 pairs of insulating filling layer 4 The overlapping rate is 15%, and the insulating filling layer 4 is an inorganic rope.

[0067] Wherein, the preparation method of the low-smoke halogen-free flame-retardant polyolefin layer comprises the following steps:

[0068] 1) Stir ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com