Nanometal hollow fiber felt current collector and preparation method thereof, lithium ion battery pole piece and lithium ion battery

A nano-metal and nano-fiber technology, applied in battery electrodes, non-aqueous electrolyte battery electrodes, secondary batteries, etc., can solve the problems that cannot fully reflect the unique properties of materials, limit the application of lithium-ion batteries, and have a large impact on irreversible properties. Good industrial application prospects, little impact of irreversible properties, good reproducible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

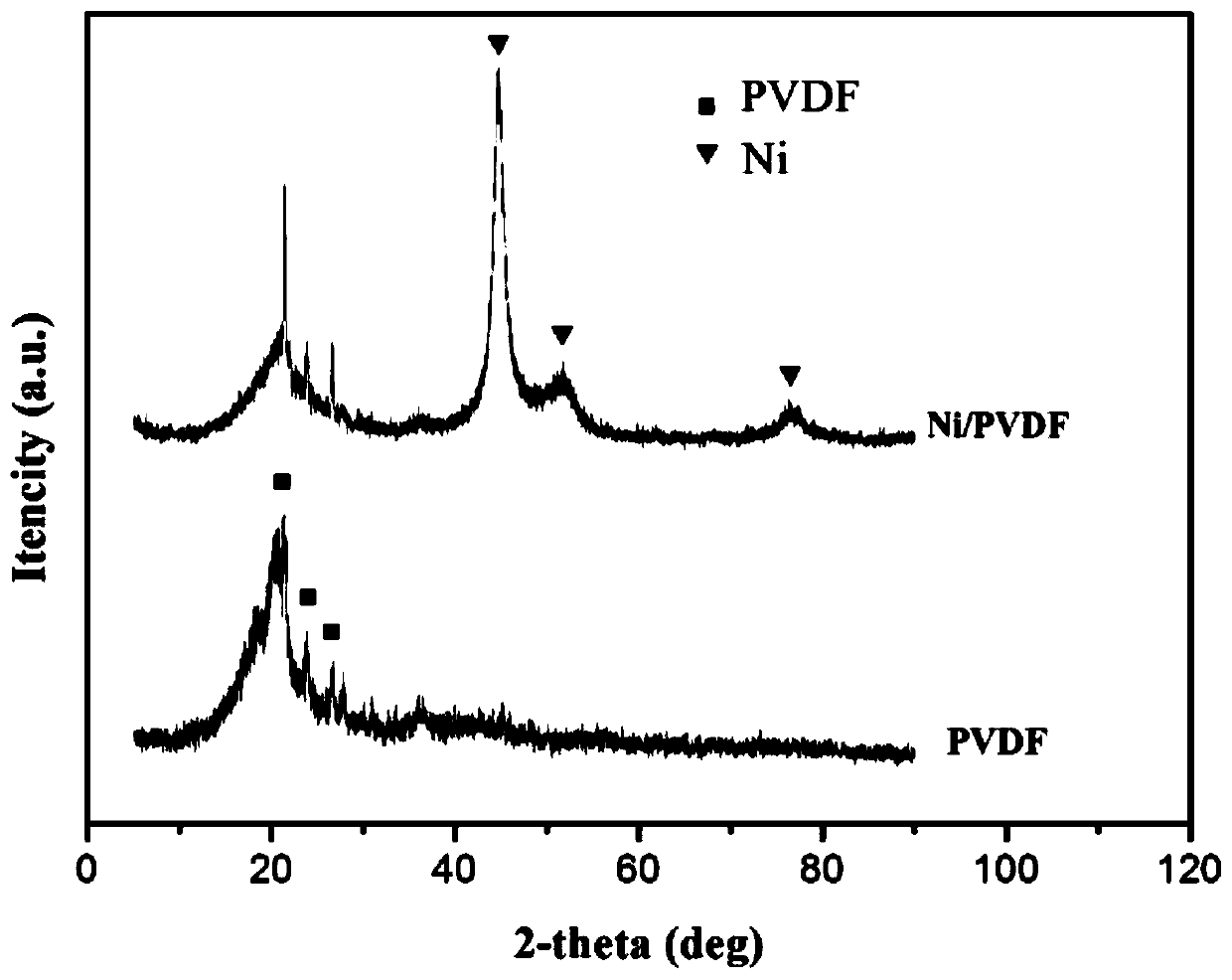

[0065] Preparation of PVDF membrane template:

[0066] First, turn on the high-voltage power supply of the electrospinning device to preheat for half an hour; then, weigh PVDF with a mass fraction of 12%, dissolve it in acetone and N,N-dimethylacetamide with a mass ratio of 3:7 In the mixed solvent, put it on a magnetic stirrer, control the temperature at 30°C, heat until the solution becomes a transparent, uniform, and bubble-free electrospinning solution, and cool for 30 minutes. Before injecting the electrospinning solution, cut the needle of the syringe into a flat mouth, and the spinning solution in the syringe is about 3ml (control the film thickness at about 40 μm). Put the aluminum foil paper on the glass plate as the receiving screen, adjust the spinning voltage and the distance between the bottom of the needle tube and the receiving glass plate, and pay attention to controlling the flow rate of the syringe pump, and start spinning. Finally, the fiber film (nanofiber...

Embodiment 2

[0082] Preparation of polystyrene (PS) membrane template:

[0083] First, turn on the high-voltage power supply of the electrospinning device to preheat for half an hour; then, weigh PS with a mass fraction of 8%, dissolve it in a mixed solvent of NMP and DMF with a mass ratio of 2:8, and place it under magnetic stirring On the device, control the temperature at 25°C, heat until the solution becomes a transparent, uniform, and bubble-free electrospinning solution, and cool for 30 minutes. Before injecting the electrospinning liquid, the needle of the syringe was cut into a round end and a flat mouth, and the spinning liquid in the syringe was approximately 4ml (the film thickness was controlled at about 45 μm). Put the aluminum foil paper on the glass plate as the receiving screen, adjust the spinning voltage and the distance between the bottom of the needle tube and the receiving glass plate, and pay attention to controlling the flow rate of the syringe pump, and start spinni...

Embodiment 3

[0100] Preparation of polymethyl methacrylate (PMMA) membrane template:

[0101] First, turn on the high-voltage power supply of the electrospinning device to preheat for half an hour; then, weigh PMMA with a mass fraction of 10%, dissolve it in a mixed solvent of DMF and acetone with a mass ratio of 3:7, and place it under magnetic stirring On the device, control the temperature at 30°C, heat until the solution becomes a transparent, uniform, and bubble-free electrospinning solution, and cool for 30 minutes. Before injecting the electrospinning solution, cut the needle of the syringe into a round end and a flat mouth, and the spinning solution in the syringe is about 3ml (control the film thickness at about 40 μm). Put the aluminum foil paper on the glass plate as the receiving screen, adjust the spinning voltage and the distance between the bottom of the needle tube and the receiving glass plate, and pay attention to controlling the flow rate of the syringe pump, and start s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com