Preparation method of milk beverage added with fresh eggs

A production method and technology for milk beverages, which are applied in dairy products, milk preparations, applications, etc., can solve the problems of single nutrient composition, single applicable population, and less applicable population, and achieve better taste, strong operability, and production efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A kind of preparation method of the milk drink of adding fresh egg, it comprises the steps:

[0033] The formula is as follows, according to the weight ratio: whole milk powder 18‰, skimmed milk powder 18‰, white sugar 50‰, egg liquid 12‰, sorbitol 3‰, mannitol 3‰, β-cyclodextrin 2‰, fruit Gum 2‰, Sodium Carboxymethyl Cellulose 1.5‰, Sodium Alginate 1.5‰, Sucralose 0.04‰, Lactic Acid 0.8‰, Citric Acid 3.2‰, Sodium Citrate 0.8‰, Yogurt Flavor 0.53‰, Potassium Sorbate 0.3‰ , The balance is pure water, and the protein content of the product is ≥1.0%.

[0034] 1) Mix 18kg of whole milk powder, 18kg of skimmed milk powder and 720kg of pure water, fully stir evenly, pump into a fermentation tank (aging tank), heat up to 90°C for sterilization for 15 minutes; then drop to 40°C to obtain milk powder for use ;

[0035]2) Mix 12kg of egg liquid after eggshell separation and beat evenly, fully stir, and shear at high speed for 20 minutes; after the mixture reaches the requiremen...

Embodiment 2

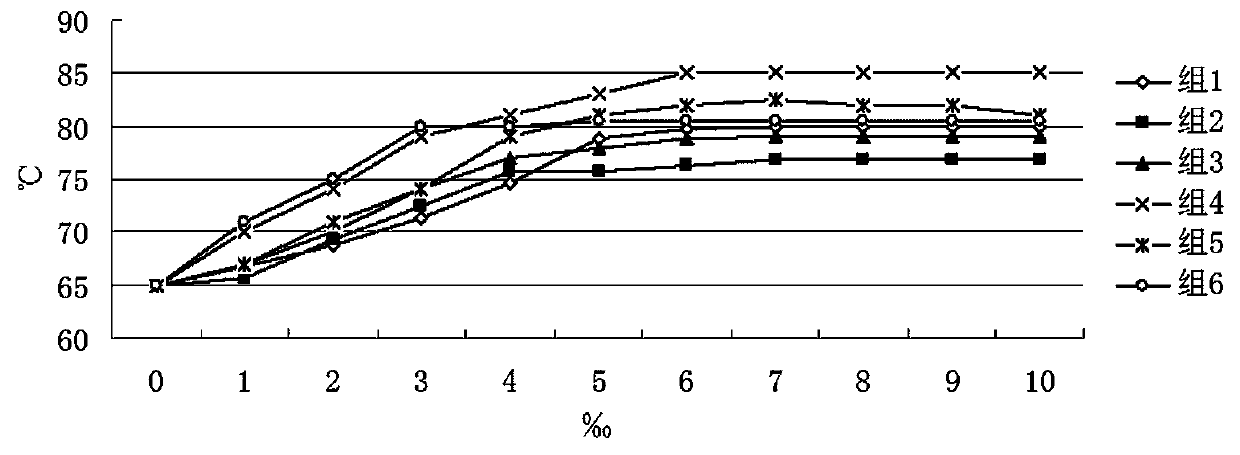

[0042] 1. The effect of sorbitol and mannitol on the sterilization temperature of egg liquid.

[0043] Egg liquid contains a certain amount of microorganisms, which requires high temperature to kill, but high temperature easily leads to egg liquid coagulation and the appearance of paste; verify the influence of sorbitol, mannitol and xylitol on sterilization temperature; The bacteria time is 5min as the consideration, and the critical maximum sterilization temperature is the appearance of a small amount of coagulation.

[0044] Group 1: Sorbitol;

[0045] Group 2: Mannitol;

[0046] Group 3: Xylitol;

[0047] Group 4: Sorbitol:Mannitol=1:1;

[0048] Group 5: sorbitol:xylitol=1:1;

[0049] Group 6: Mannitol: Xylitol = 1:1.

[0050] The setting gradient of the addition amount of each group is 0, 1‰, 2‰, 3‰, 4‰, 5‰, 6‰, 7‰, 8‰, 9‰, 10‰.

[0051] like figure 1 As shown in the figure, with the increase of the addition amount, the maximum temperature also increases. Among the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com