A method and device for manufacturing an ultra-thin-walled hollow microsphere optical resonant cavity

A microsphere resonant cavity and hollow microsphere technology, which is applied in the preparation of microspheres, microcapsule preparations, etc., can solve the problems of short arc discharge, difficult to precisely control the expansion process of hollow capillaries, and thick wall thickness of microspheres. Distortion, avoidance of asymmetrical micro-pressure effects, effect of reducing eccentricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

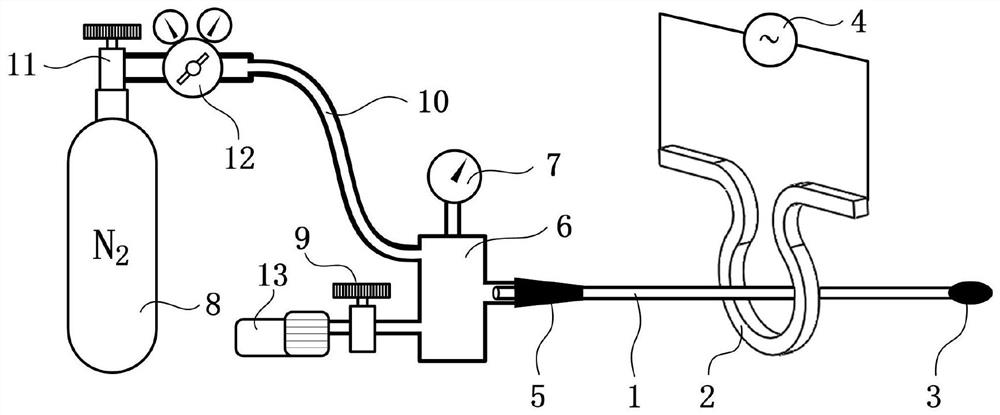

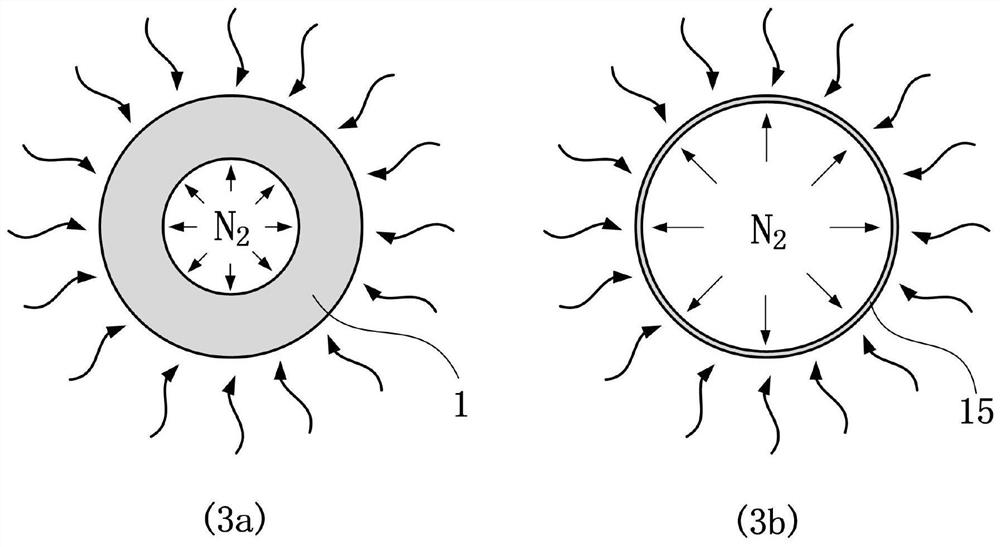

[0023] A method and device for manufacturing an ultra-thin-walled hollow microsphere optical resonant cavity of the present invention adopts a full-angle non-contact uniform radiation heating molding method, uniformly heats to a molten state by non-contact radiation along the circumferential direction of the hollow optical fiber, and synchronously inside the hollow optical fiber Applying air pressure, the outer wall of the optical fiber is gradually expanded and formed under the action of the internal and external pressure difference, and a high-quality hollow microsphere resonator is prepared.

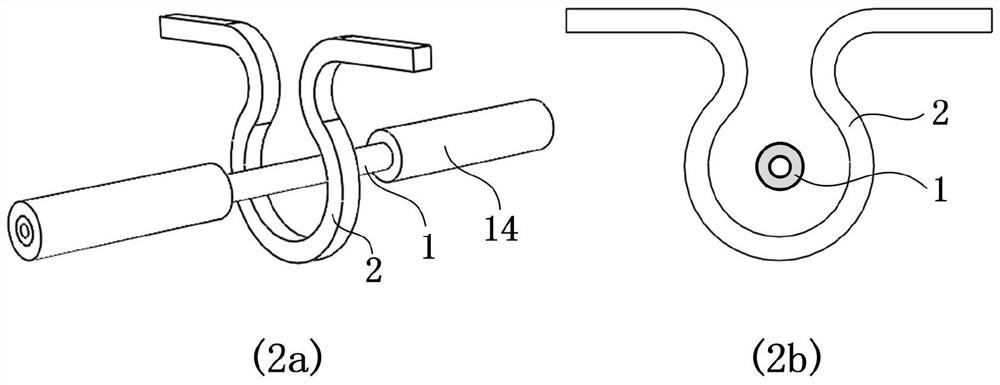

[0024] like figure 1 As shown, it is an ultra-thin-walled hollow microsphere optical resonant cavity manufacturing device of the present invention, which is composed of two parts: a heating system and a pressurizing system. Among them, the heating system includes an Ω-shaped heating ring 2 and a control power supply 4, which provide the hollow silica optical fiber 1 with a high temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com