High-toughness cement-based composite material and preparation method thereof

A composite material, cement-based technology, applied in cement mixing devices, clay preparation devices, chemical instruments and methods, etc., can solve the problems of large tension eccentricity, inconvenient clamping, complex structure, etc., and achieve the ultimate tensile strain. Large, less auxiliary tools, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

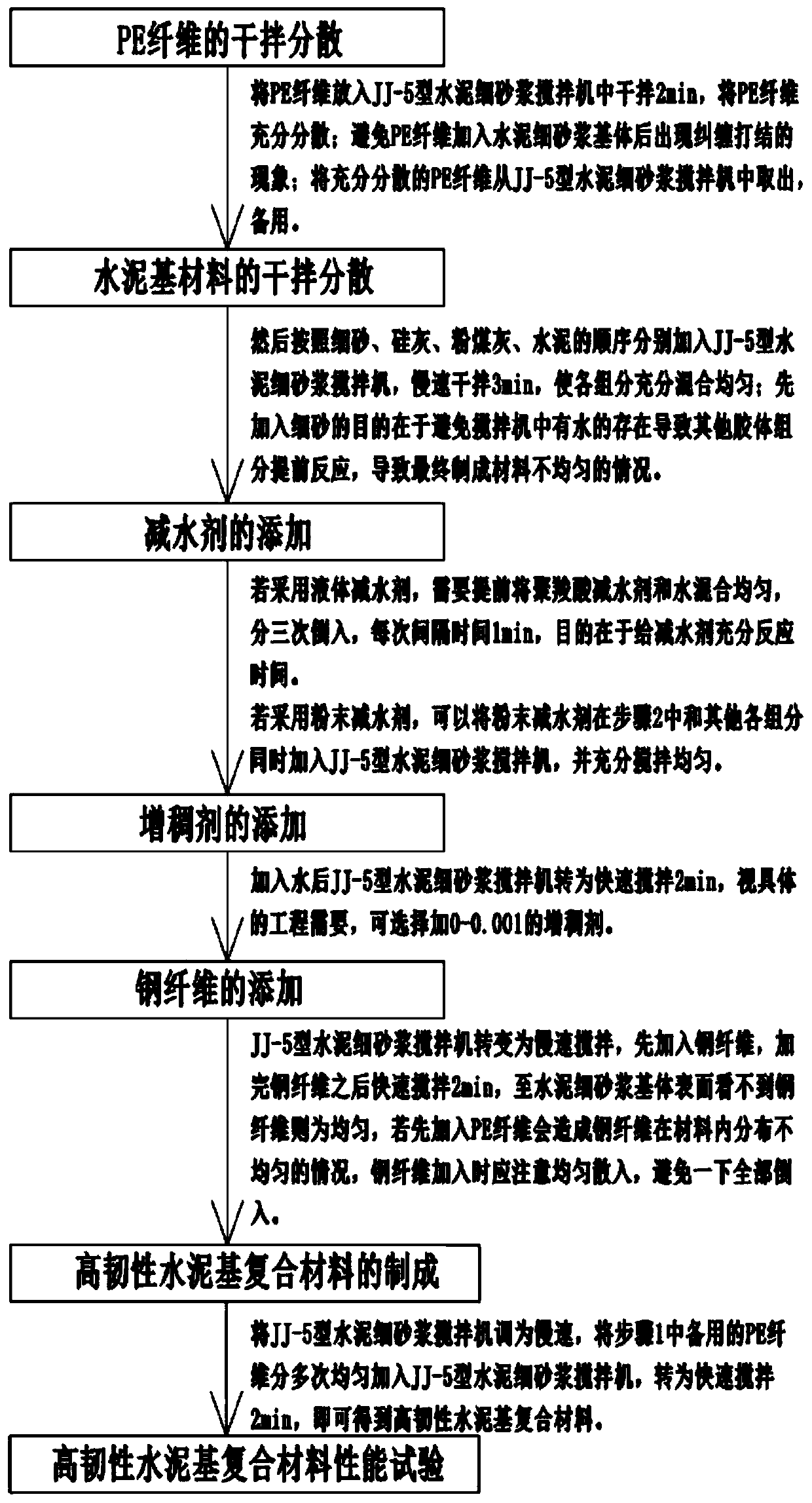

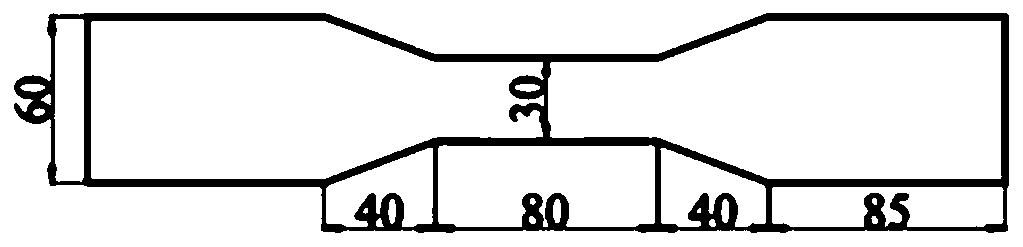

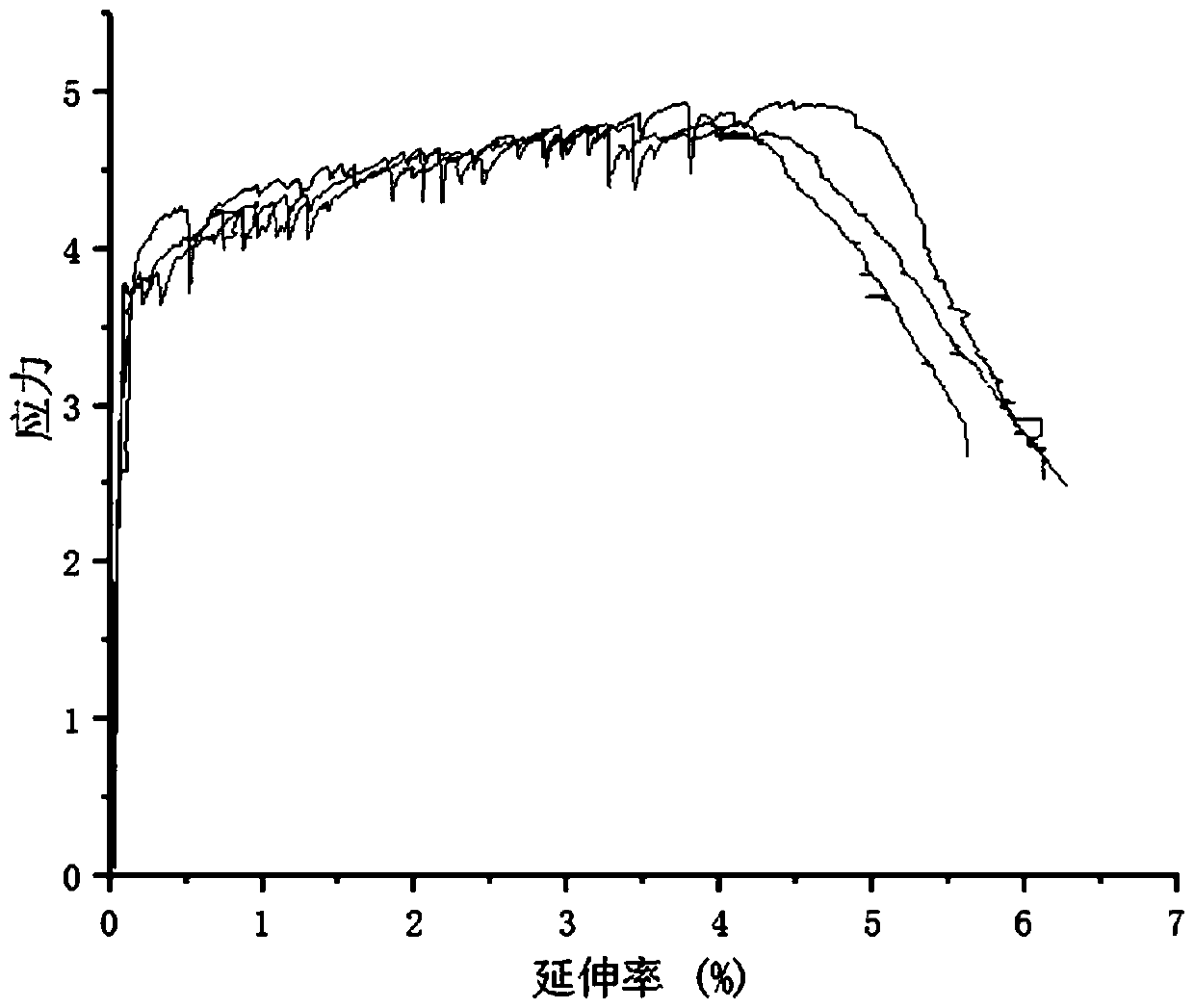

[0040] A preparation method of high-toughness cement-based composite material, such as figure 1 As shown, the following steps are included: Step 1: Dry mixing and dispersion of PE fiber; Step 2: Dry mixing and dispersion of cement-based materials; Step 3: Adding water reducing agent; Step 4: Adding thickener; Step 5: Addition of steel fibers; Step 6: Preparation of high-toughness cement-based composites; Step 7: Tensile test of high-toughness cement-based composites using displacement gauge fixtures; Step 8: Using test fixtures to test high-toughness cement-based composites Axial tensile tests were performed.

[0041] In specific implementation, such as figure 1 Shown, the preparation method of high-toughness cement-based composite material comprises the following steps:

[0042] Step 1: Dry mixing and dispersion of PE fiber.

[0043] Put the PE fiber into the JJ-5 cement fine mortar mixer and dry mix it for 2 minutes to fully disperse the PE fiber; avoid entanglement and k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com