Quick-setting self-leveling mortar

A self-leveling mortar and fast technology, applied in the field of building materials, can solve problems such as unstable construction quality, unstable aggregate gradation, and influence on construction progress, and achieve the effects of facilitating subsequent projects, convenient and fast construction, and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

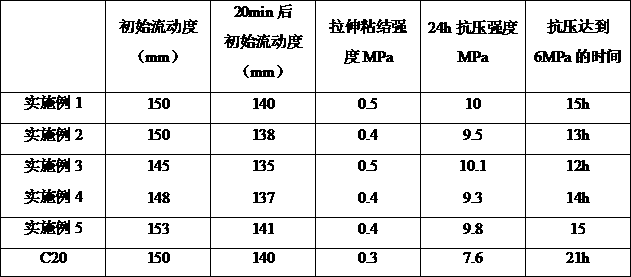

Examples

Embodiment 1

[0052] The present invention is composed of the following components by weight percentage: 42.5 strength ordinary portland cement: 18%; stone powder: 7%; 0-1.2mm machine-made sand: 42%; 1.2-2.4mm machine-made sand: 15%; 4.75mm machine-made sand: 17.86%; cellulose ether: 0.02%; thixotropic lubricant 0.02%; water reducing agent 0.1%.

[0053] Take a certain amount of the above-mentioned dry-mixed masonry mortar, put in the water corresponding to the amount of water added, mix it through a laboratory mixer, test its various indicators and conduct construction tests for workers.

Embodiment 2

[0055] The present invention consists of the following components by weight percentage: 42.5 strength ordinary Portland cement: 17%; stone powder: 9%; 0-1.2mm machine-made sand: 42%; 1.2-2.4mm machine-made sand: 13%; 4.75mm machine-made sand: 18.85%; cellulose ether: 0.03%; thixotropic lubricant: 0.02%; water reducer: 0.1%.

Embodiment 3

[0057] The present invention consists of the following components by weight percentage: 42.5 strength ordinary portland cement: 16%; stone powder: 8%; 0-1.2mm machine-made sand: 42%; 1.2-2.4mm machine-made sand: 10%; 2.4~ 4.75mm machine-made sand: 23.85%; cellulose ether: 0.03%; thixotropic lubricant 0.02%; water reducing agent 0.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com