Colorless transparent non-fluorine polyimide film with low thermal expansion coefficient and preparation method and application thereof

A technology of polyimide film and low thermal expansion coefficient is applied in the field of preparation of colorless transparent non-fluorine polyimide film with low thermal expansion coefficient, which can solve problems such as no systematic reports.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Embodiment 1 prepares a colorless transparent polyimide film by the polymerization of hydrogenated pyromellitic dianhydride (HPMDA) and 2-methyl-4,4'-diaminobenzanilide (MeDABA):

[0058]Add 24.1290g (0.1mol) MeDABA and 100g NMP into a 500mL three-neck flask equipped with a heating mantle, mechanical stirring, thermometer, water separator, and reflux condenser. Nitrogen gas was introduced and a clear solution was obtained after mechanical stirring for 20 min. 22.4170 g (0.1 mol) HPMDA was added under stirring, and the viscosity of the system gradually increased. Add 8.6g of NMP and stir at room temperature for 30min to obtain a viscous solution. Add 0.5g pyridine and 150mL toluene as catalyst and azeotropic dehydrating agent respectively. When the system temperature rises to 130-140°C, the toluene / water azeotrope evaporates out of the water separator. Keep reflux for dehydration until no water drops come out of the system. Continue to heat up to 180°C and keep the t...

Embodiment 2

[0069] Embodiment 2 prepares a colorless transparent polyimide film by the polymerization of hydrogenated pyromellitic dianhydride (HPMI) and 2-chloro-4,4'-diaminobenzoanilide (ClDABA):

[0070] Resin and film preparation are as in Example 1, the difference is that 2-methyl-4,4'-diaminobenzanilide (MeDABA) is replaced by 2-chloro-4,4'-diaminobenzanilide (ClDABA ). Typical chemical structures of the as-prepared films are shown below.

[0071]

[0072] Number average molecular weight M n =37634 g / mol, n=83.

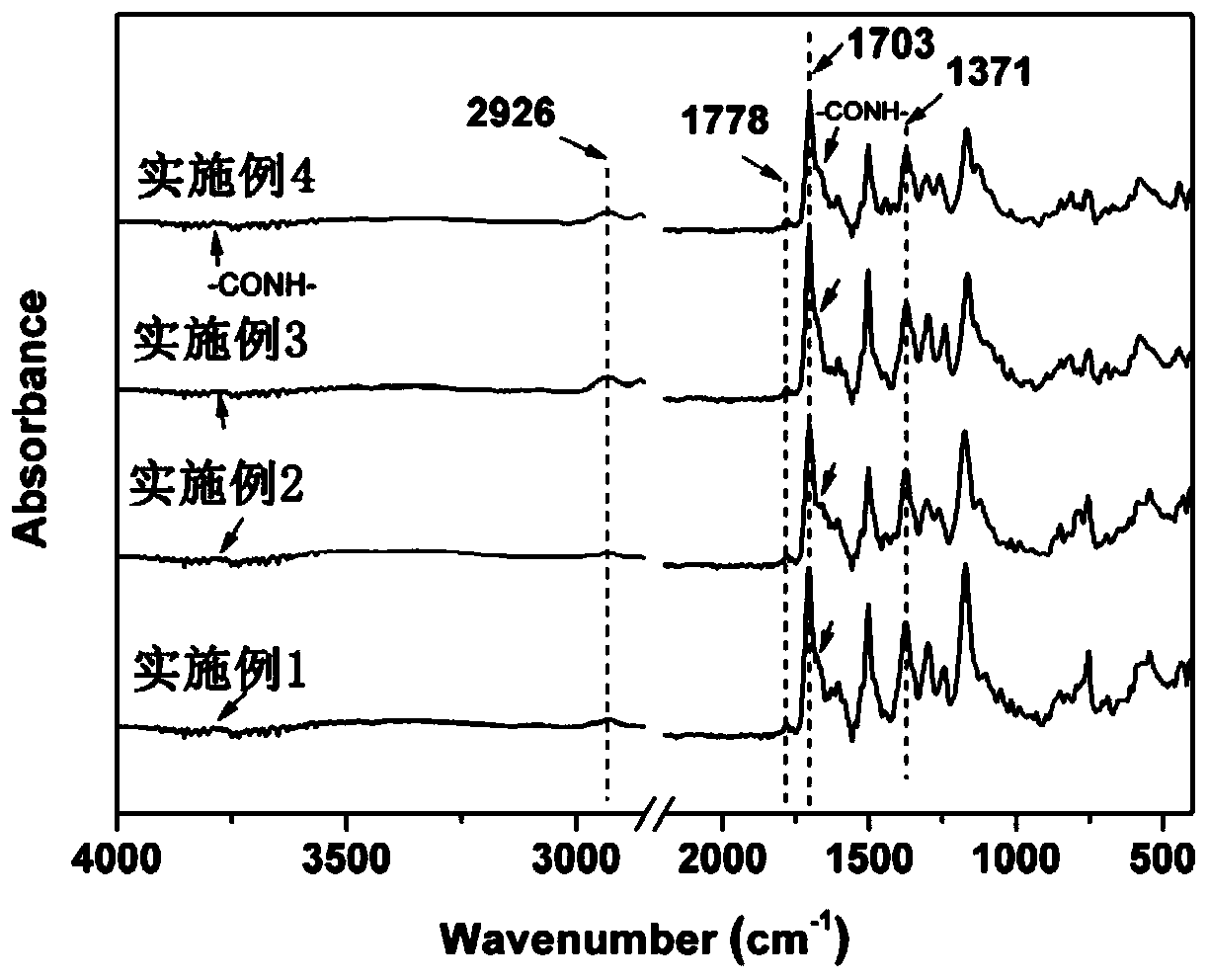

[0073] Infrared spectrum as attached figure 1 shown;

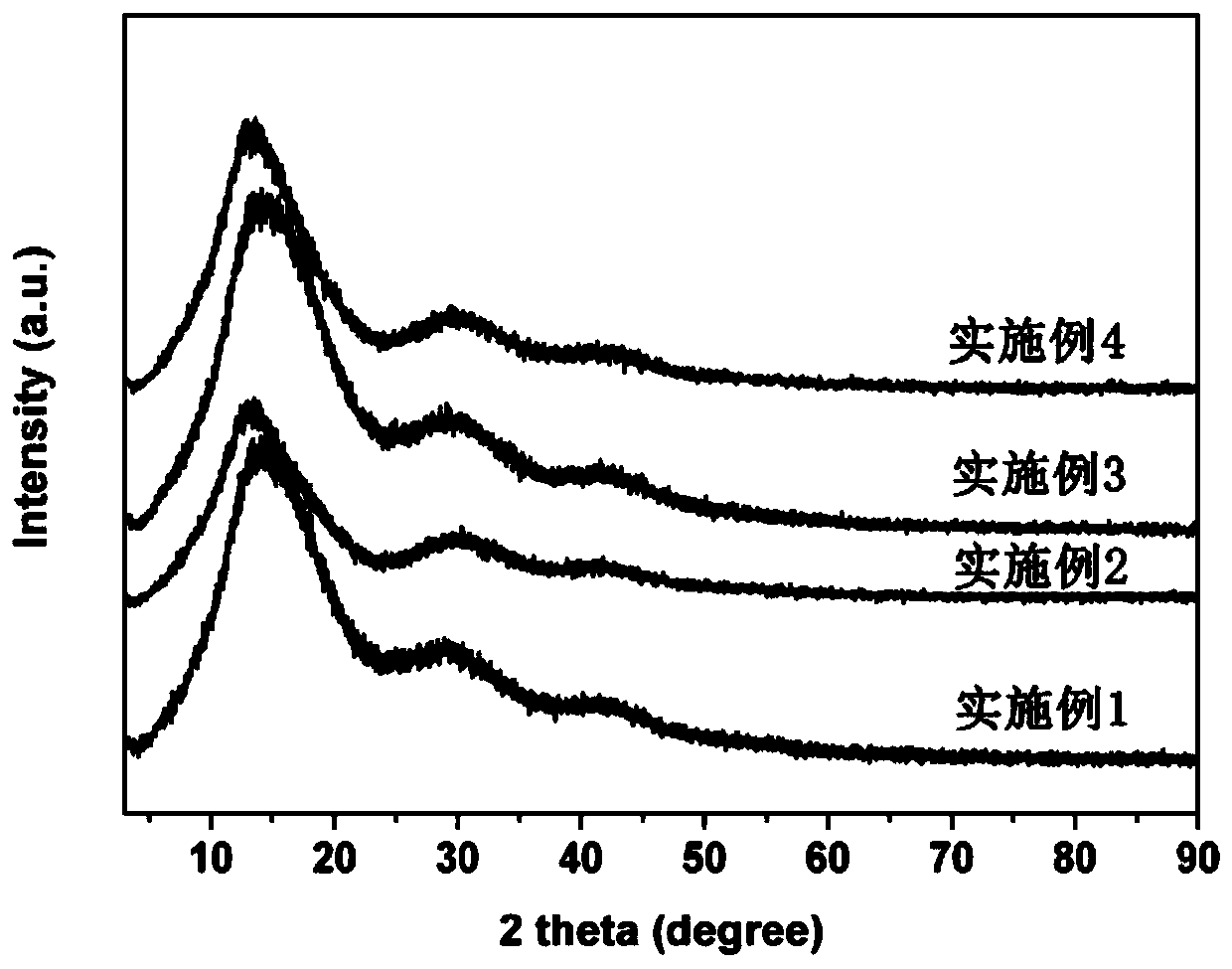

[0074] XRD spectrum is attached figure 2 shown;

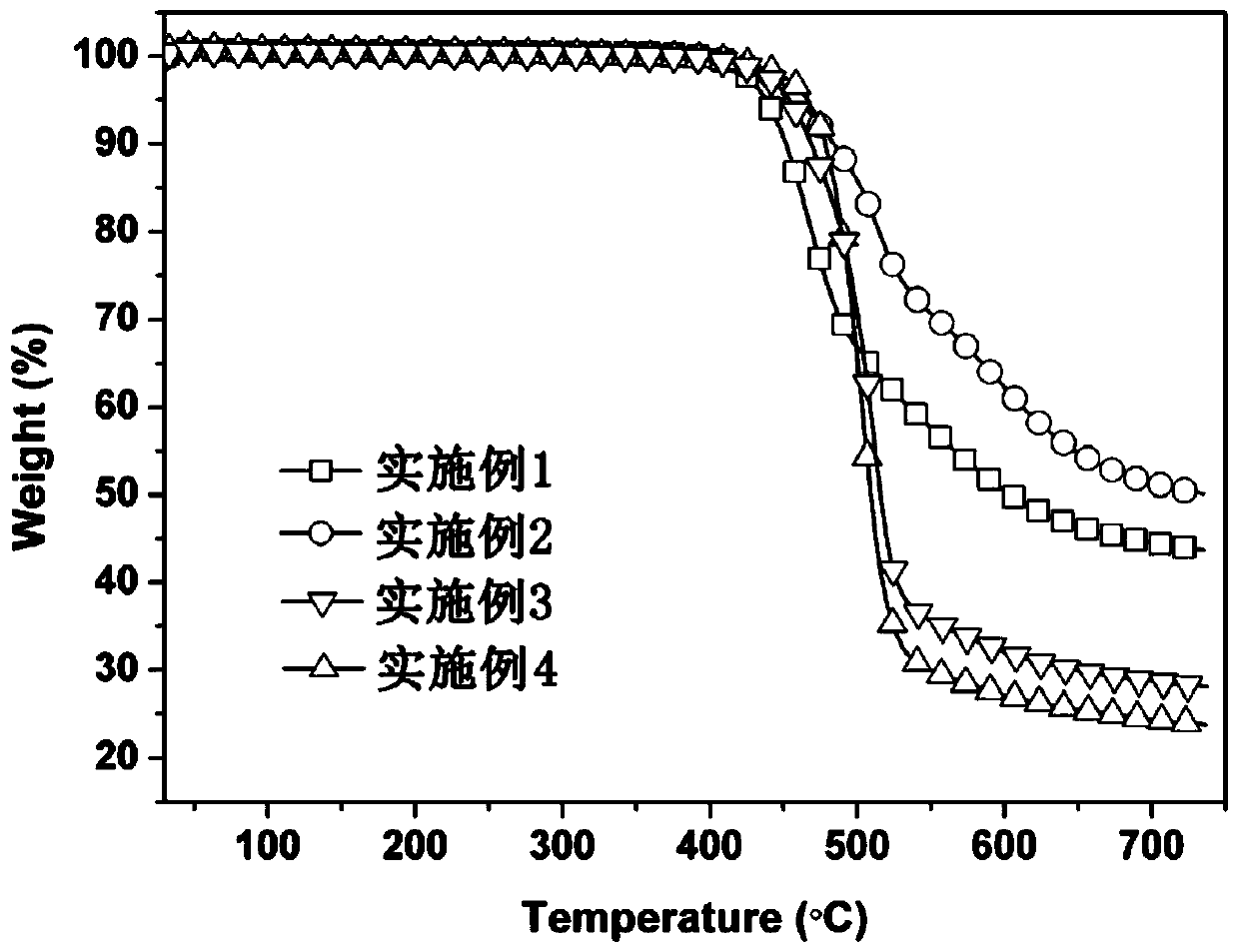

[0075] The TGA spectrum is attached image 3 shown;

[0076] The DSC spectrum is attached Figure 4 shown;

[0077] The TMA spectrum is attached Figure 5 shown;

[0078] The UV-Vis spectrum is attached Figure 6 shown.

[0079] The performance data are shown in Table 1.

Embodiment 3

[0080] Example 3 Preparation of colorless transparent polymer by polymerization of hydrogenated 3,3',4,4'-biphenyltetracarboxylic dianhydride (HBPDA) and 2-methyl-4,4'-diaminobenzoanilide (MeDABA) Imide film:

[0081] The preparation of the resin and film was as in Example 1, except that hydrogenated pyromellitic dianhydride (HPMI) was replaced by hydrogenated 3,3',4,4'-biphenyltetracarboxylic dianhydride (HBPDA). Typical chemical structures of the as-prepared films are shown below.

[0082]

[0083] Number average molecular weight M n =26295 g / mol, n=51.

[0084] Infrared spectrum as attached figure 1 shown;

[0085] XRD spectrum is attached figure 2 shown;

[0086] The TGA spectrum is attached image 3 shown;

[0087] The DSC spectrum is attached Figure 4 shown;

[0088] The TMA spectrum is attached Figure 5 shown;

[0089] The UV-Vis spectrum is attached Figure 6 shown.

[0090] The performance data are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com