Water-based non-stick coating and preparation method thereof

A non-stick coating, water-based technology, used in anti-corrosion coatings, coatings, etc., can solve the problems of easy corrosion and peeling, non-stick decline, shortening the service life of coatings, etc., to solve the problems of adhesion and baking cracking, good temperature The effect of dispersing the area and increasing the hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

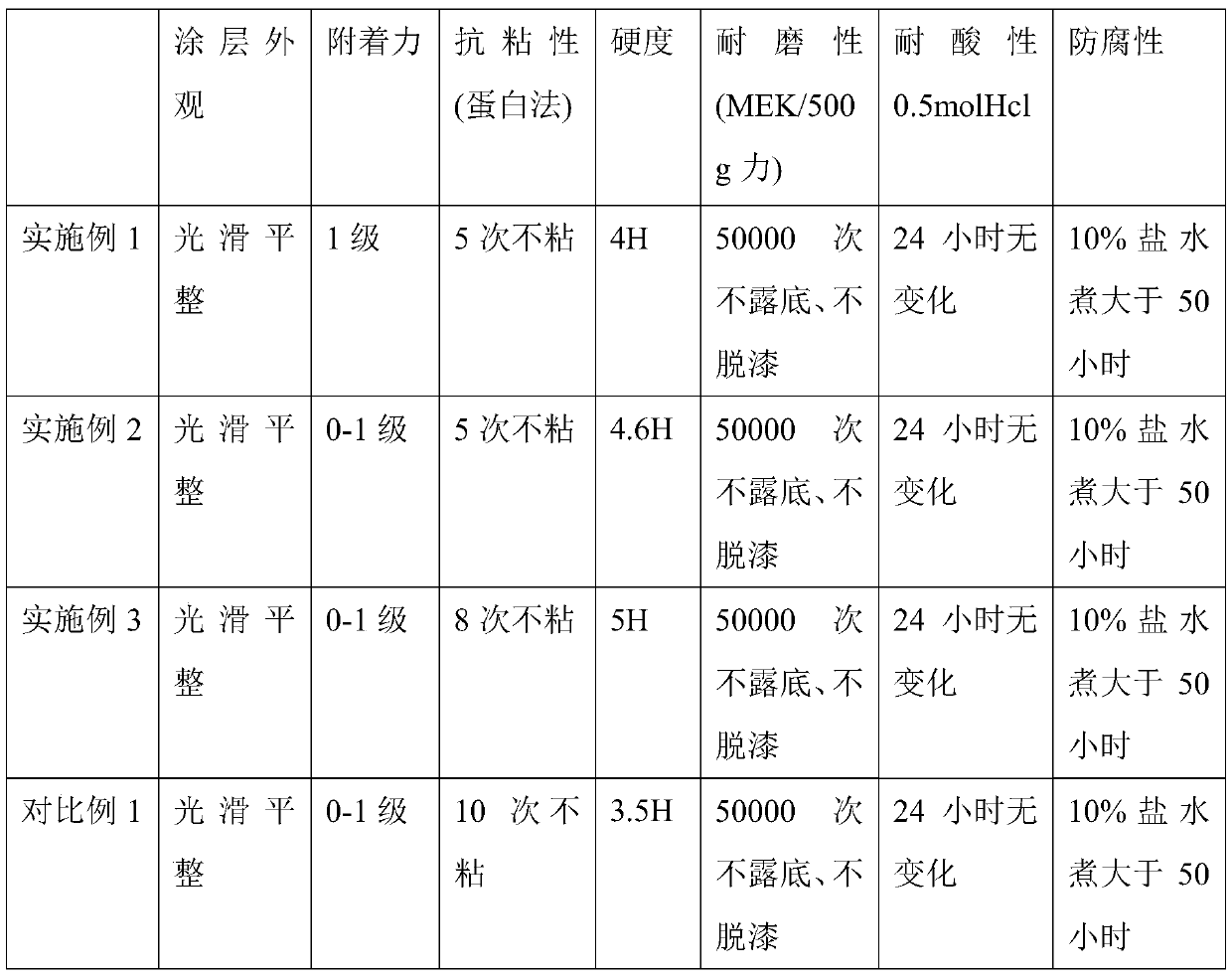

Embodiment 1

[0024] A water-based non-stick coating, including a primer and a topcoat; the primer includes the following components in parts by weight: 35 parts of polytetrafluoroethylene emulsion, 15 parts of aluminum oxide, 6 parts of carbon black, 9 parts of aluminum powder, silicon carbide 15 parts, 15 parts of water, 30 parts of water-based polyethersulfone resin emulsion, 30 parts of modified polyamide-imide resin and 20 parts of hydrophobically modified polyacrylate alkali swelling type emulsion; the top coat includes the following parts by weight Components: 70 parts of polytetrafluoroethylene emulsion, 15 parts of modified acrylic acid emulsion, 25 parts of hydrophobically modified polyacrylic acid alkali-swellable emulsion, 7 parts of titanium dioxide, 20 parts of water, 1 part of palladium acetate and 1 part of rhodium carbonyl.

[0025] A kind of water-based non-stick coating, comprises the following steps:

[0026] (1) Preparation of water-based polyethersulfone resin emulsion...

Embodiment 2

[0031] A water-based non-stick coating, including a primer and a topcoat; the primer includes the following components in parts by weight: 25 parts of polytetrafluoroethylene emulsion, 10 parts of aluminum oxide, 4 parts of carbon black, 6 parts of aluminum powder, silicon carbide 10 parts, 10 parts of water, 20 parts of water-based polyethersulfone resin emulsion, 20 parts of modified polyamide-imide resin and 13 parts of hydrophobically modified polyacrylate alkali swelling type emulsion; the topcoat includes the following parts by weight Components: 60 parts of polytetrafluoroethylene emulsion, 10 parts of modified acrylic acid emulsion, 15 parts of hydrophobically modified polyacrylic acid alkali-swellable emulsion, 5 parts of titanium dioxide, 15 parts of water, 0.5 part of palladium acetate and 0.5 part of rhodium carbonyl.

[0032] A kind of water-based non-stick coating, comprises the following steps:

[0033] (1) Preparation of water-based polyethersulfone resin emuls...

Embodiment 3

[0038] A water-based non-stick coating, including a primer and a topcoat; the primer includes the following components in parts by weight: 15 parts of polytetrafluoroethylene emulsion, 3 parts of aluminum oxide, 2 parts of carbon black, 1 part of aluminum powder, silicon carbide 2 parts, 3 parts of water, 5 parts of water-based polyethersulfone resin emulsion, 5 parts of modified polyamide-imide resin and 5 parts of hydrophobically modified polyacrylate alkali-swellable emulsion; the topcoat includes the following parts by weight Components: 50 parts of polytetrafluoroethylene emulsion, 5 parts of modified acrylic acid emulsion, 3 parts of hydrophobically modified polyacrylic acid salt alkali-swellable emulsion, 1 part of titanium dioxide, 6 parts of water, 0.2 part of palladium acetate and 0.3 part of rhodium carbonyl.

[0039] A kind of water-based non-stick coating, comprises the following steps:

[0040] (1) Preparation of water-based polyethersulfone resin emulsion: mix pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com