Epoxy mortar coating and preparation method thereof

An epoxy mortar and coating technology, applied in epoxy resin coatings, coatings and other directions, can solve the problems of thick coating cracking, inability to use normally, cracking and other problems, and achieve the effect of good hardness and solvent resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

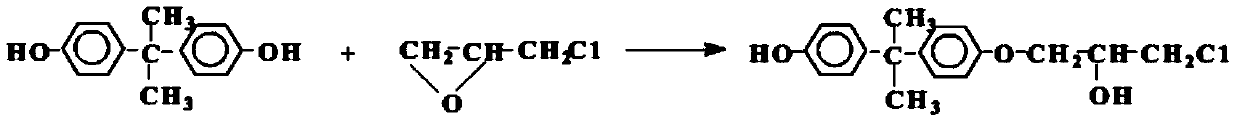

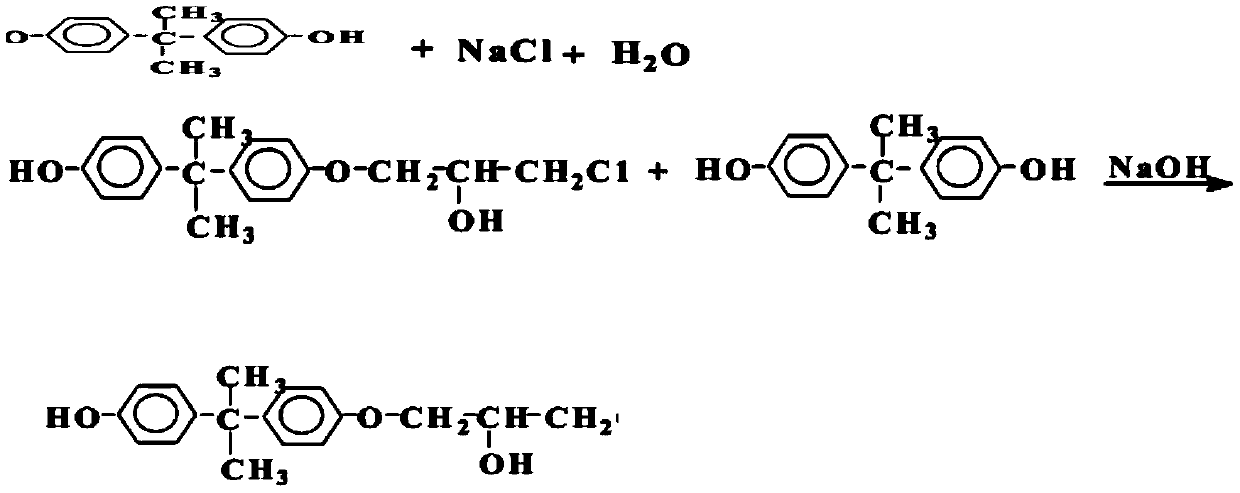

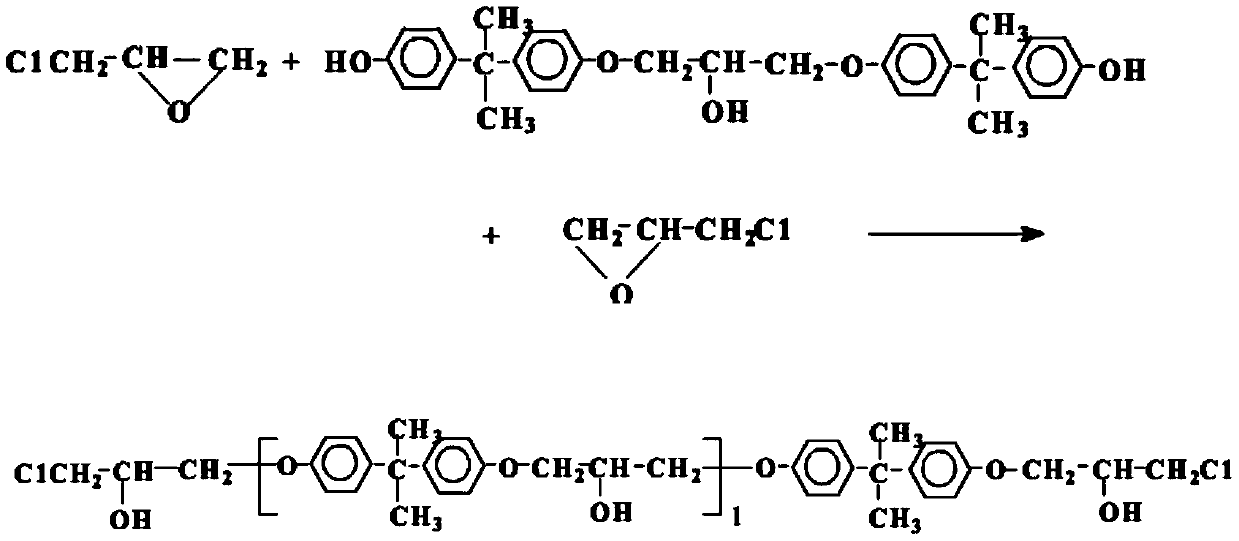

Method used

Image

Examples

Embodiment 1-6

[0041] A kind of waterborne epoxy mortar paint, by weight, comprises following component:

[0042] Component A: 30-50 parts of epoxy curing agent, 30-40 parts of deionized water, 0.1-0.3 parts of defoamer, 0.1-0.4 parts of dispersant, 0.2-0.6 parts of substrate wetting agent, 0.5 parts of leveling agent -0.6 copies;

[0043] Component B: 85-95 parts of epoxy resin, 5-15 parts of aliphatic glycidyl ether;

[0044] Component C: 80-100 parts of quartz sand, 20-40 parts of Portland cement, 0.5-1.5 parts of wood fiber, and 1-3 parts of PP fiber.

[0045] The components and proportioning ratio of each embodiment are shown in Table 1.

[0046] The preparation method of the waterborne epoxy mortar coating of embodiment 1-6 is as follows:

[0047] (1) Mix deionized water, defoamer, dispersant, substrate wetting agent evenly to obtain slurry A;

[0048] (2) Add epoxy curing agent and leveling agent to slurry A, and mix evenly to obtain slurry B, which is component A;

[0049] (3) Dil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com