Preparation method of purple sweet potato vinegar

A production method and technology of purple sweet potato, which are applied in the food field, can solve the problems of large loss of anthocyanins in purple sweet potato, low content of anthocyanins in purple sweet potato vinegar, and poor stability, and achieve high anthocyanin content, improved stability, and simple production process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

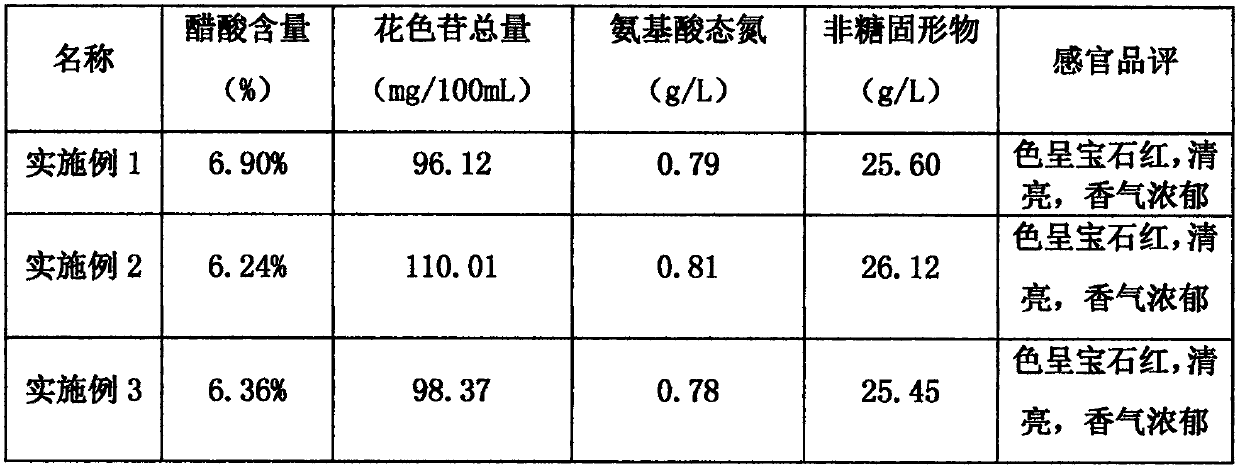

Examples

Embodiment 1

[0025] A kind of preparation method of purple sweet potato vinegar, implementation steps are as follows:

[0026] (1) Purple sweet potato treatment: wash and crush the purple sweet potato, add food grade 6% sulfurous acid 60ppm according to the total mass of fresh potato crushed matter, add water and grind it into potato paste, the mass ratio of fresh potato crushed matter to the amount of water added is 1 : 2.0;

[0027] (2) Filtration of potato paste: pass the potato paste through a 50-mesh sieve to obtain starch and potato residue mixture A and pigment water B;

[0028] (3) Extraction of anthocyanins in starch and potato residue mixture

[0029] (3.1) Pigment extraction: Dilute starch and potato residue mixture A with water, the ratio of material weight to water addition is 1:2.0, use food grade lactic acid to adjust the pH value to 3.0, extract for 11 hours, and then pass the mixture of potato residue and water 50 mesh sieves to obtain starch and potato residue mixture C...

Embodiment 2

[0038] A kind of preparation method of purple sweet potato vinegar, lies in following implementation steps:

[0039] A kind of preparation method of purple sweet potato vinegar, implementation steps are as follows:

[0040] (1) Purple sweet potato treatment: wash and crush the purple sweet potato, add food grade 6% sulfurous acid 60ppm according to the total mass of fresh potato crushed matter, add water and grind it into potato paste, the mass ratio of fresh potato crushed matter to the amount of water added is 1 : 2.25;

[0041] (2) Filtration of potato paste: pass the potato paste through a 60-mesh sieve to obtain starch and potato residue mixture A and pigment water B;

[0042] (3) Extraction of anthocyanins in starch and potato residue mixture

[0043] (3.1) Pigment extraction: starch potato residue mixture A is diluted with water, the ratio of the weight of the material to the amount of water added is 1:2.25, the pH value is adjusted to 3.25 with food grade citric acid, ...

Embodiment 3

[0052] A kind of preparation method of purple sweet potato vinegar, implementation steps are as follows:

[0053] (1) Purple sweet potato treatment: wash and crush the purple sweet potato, add food grade 6% sulfurous acid 60ppm according to the total mass of fresh potato crushed matter, add water and grind it into potato paste, the mass ratio of fresh potato crushed matter to the amount of water added is 1 : 2.5;

[0054] (2) Filtration of potato paste: pass the potato paste through a 70-mesh sieve to obtain starch and potato residue mixture A and pigment water B;

[0055] (3) Extraction of anthocyanins in starch and potato residue mixture

[0056] (3.1) Pigment extraction: starch potato residue mixture A is diluted with water, the ratio of the weight of the material to the amount of water added is 1:2.5, the pH value is adjusted to 3.5 with food-grade malic acid, and the mixture of potato residue and water is extracted for 10 hours. Pass through a 70-mesh sieve to obtain st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com