Acid-base fancy cashmere-like acrylic yarn and spinning process thereof

The technology of imitating cashmere and acrylic fiber is applied in the field of acid-base interlocking cashmere-like acrylic yarn and its spinning process, which can solve the problems of long process and time-consuming of interlocking process, save dyeing cost and achieve good yarn resilience. , The effect of fluffy and soft appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

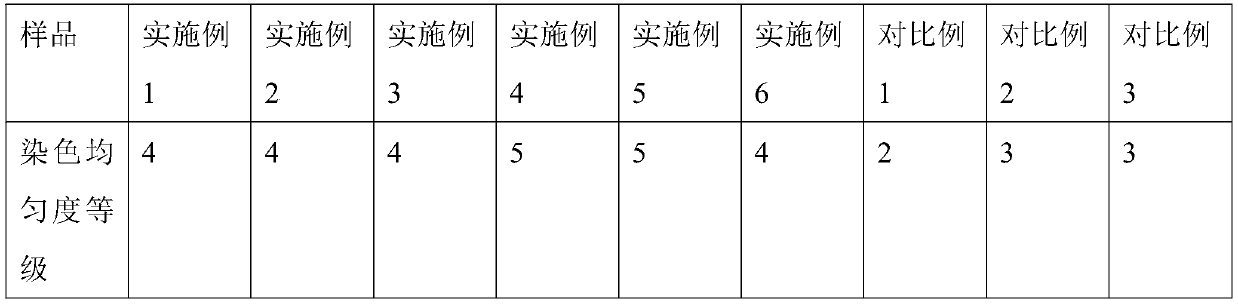

Examples

Embodiment 1

[0029] Embodiment 1 A kind of acid-base interlaced imitation cashmere acrylic yarn

[0030] The acid-base interlaced imitation cashmere acrylic yarn is obtained by spinning the following raw materials and their mass percentages: 5% acid-dyeable polyacrylonitrile fiber, 20% high-shrinkage acrylic fiber, and 75% conventional acrylic fiber; the conventional acrylic fiber is selected from cotton fiber. The relative humidity of each raw material is 50, and the temperature is 20°C.

[0031] The preparation method of the acid-dyeable polyacrylonitrile fiber is as follows: acrylonitrile monomer and acrylic acid amino ester are mixed in a mass ratio of 0.5:3, deionized water is added, initiator potassium persulfate is protected by nitrogen, and polymerized at 60°C for 5 hours , wash with acetone, water and mass fraction in turn with 20% NaSCN aqueous solution, and dry to obtain AN / TAM copolymer; AN / TAM copolymer and polyacrylonitrile are mixed in a mass ratio of 6.5:94, and the concen...

Embodiment 2

[0042] Embodiment 2 A kind of acid-base interlaced imitation cashmere acrylic yarn

[0043] The acid-base interlaced imitation cashmere acrylic yarn is obtained by spinning the following raw materials and their mass percentages: 40% acid-dyeable polyacrylonitrile fiber, 40% high-shrinkage acrylic fiber, and 20% conventional acrylic fiber; the conventional acrylic fiber is selected from cotton fiber. The relative humidity of above-mentioned raw material is 80, and temperature is 30.

[0044] The preparation method of the acid dyeable polyacrylonitrile fiber is: carry out the copolymerization reaction of acrylonitrile monomer and acrylic acid amino ester according to the mass ratio of 2:5, obtain AN / TAM copolymer; combine AN / TAM copolymer and polyacrylonitrile Mix by mass ratio 7:80, other steps are with the preparation method described in Example 1.

[0045] The spinning process of the cashmere-like acrylic yarn with acid-base pattern is the same as that described in Example ...

Embodiment 3

[0046] Embodiment 3 A kind of acid-base interlaced imitation cashmere acrylic yarn

[0047] The cashmere-like acrylic yarn with acid-base interlaced patterns is obtained by spinning the following raw materials and their mass percentages: 10% of acid-dyeable polyacrylonitrile fiber, 40% of high-shrinkage acrylic fiber, and 50% of conventional acrylic fiber. The conventional acrylic fibers are polyester fibers. The relative humidity of above-mentioned raw material is 60, and temperature is 23.

[0048] The preparation method of the acid dyeable polyacrylonitrile fiber is as described in Example 2.

[0049] The spinning process of the cashmere-like acrylic yarn with acid-base pattern is the same as that described in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com