Humidity and stress double-parameter micro-optical fiber sensor based on carbon nanotube compound

A carbon nanotube and micro-fiber technology, applied in the field of stress detection and relative air humidity, can solve the problems of inability to measure humidity and pressure at the same time, low sensitivity, etc., and achieve the effects of simple structure, high sensitivity and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

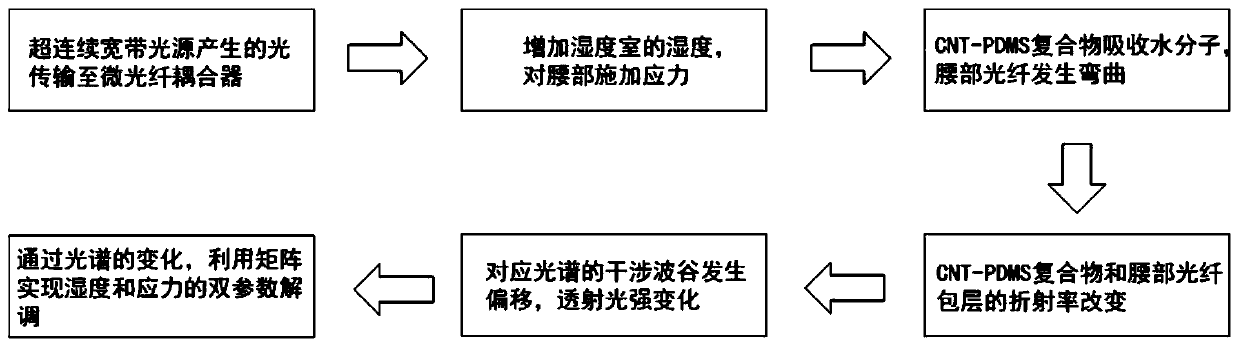

Method used

Image

Examples

Embodiment Construction

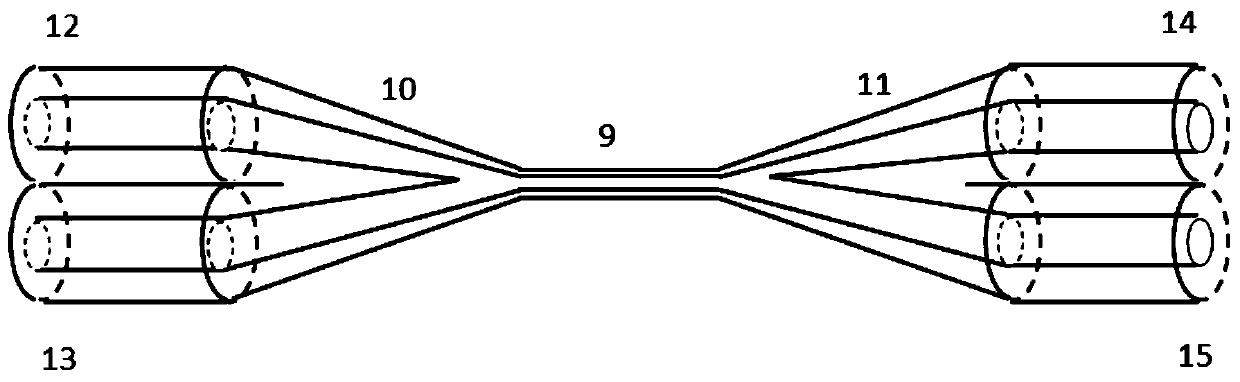

[0025] A humidity and stress dual-parameter micro-fiber sensor based on a carbon nanotube composite, the dual-parameter micro-fiber sensor includes a supercontinuous broadband light source, a single-mode fiber, a micro-fiber coupler, carbon nanotube-polydimethylsiloxane Alkane (CNT-PDMS) composite and spectrometer. Described micro-fiber coupler is that the middle part of two single-mode optical fibers is wound together, utilizes hydrogen-oxygen flame tapering machine to carry out heating tapering to the winding area, forms micro-fiber coupler (such as image 3 shown), and then the carbon nanotube-polydimethylsiloxane (CNT-PDMS) composite was evenly coated on the waist surface of the microfiber coupler.

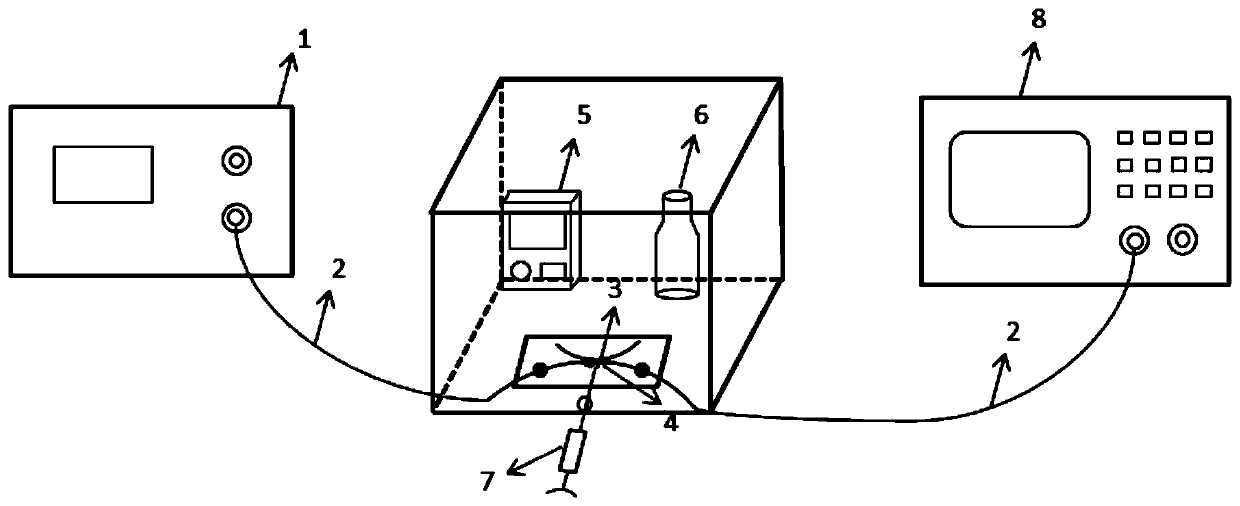

[0026] like figure 2 The detection system shown includes a dual-parameter microfiber sensor, including a supercontinuum broadband light source, a single-mode fiber, a microfiber coupler, a carbon nanotube-polydimethylsiloxane (CNT-PDMS) composite, an electronic hygrometer, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com