Self-headspace gas chromatography sample injector

A sample injector, air phase technology, applied in instruments, scientific instruments, measuring devices, etc., can solve problems such as rapid discharge of samples that cannot be sampled, reduced activity of sampled objects, and improper protection measures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

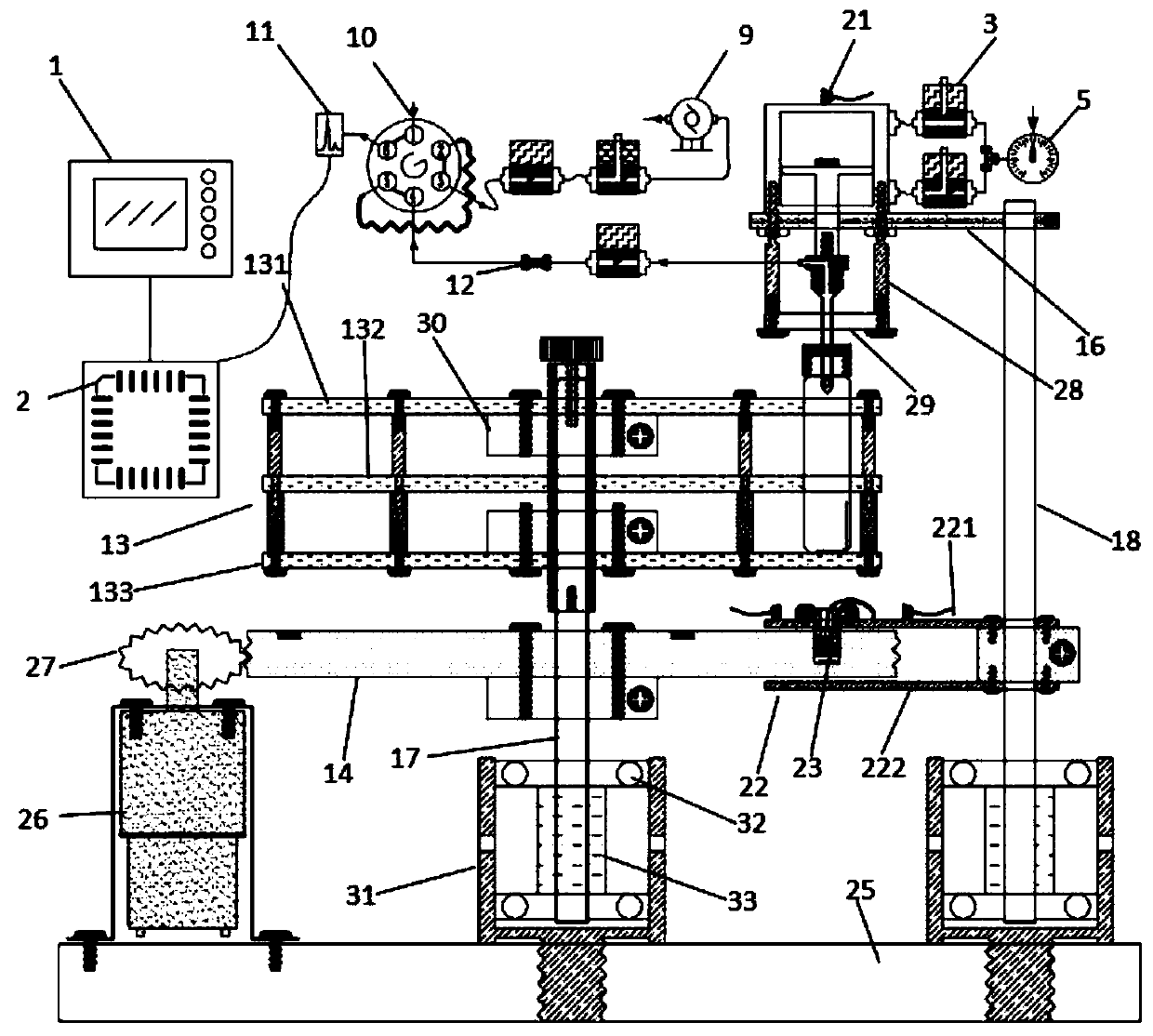

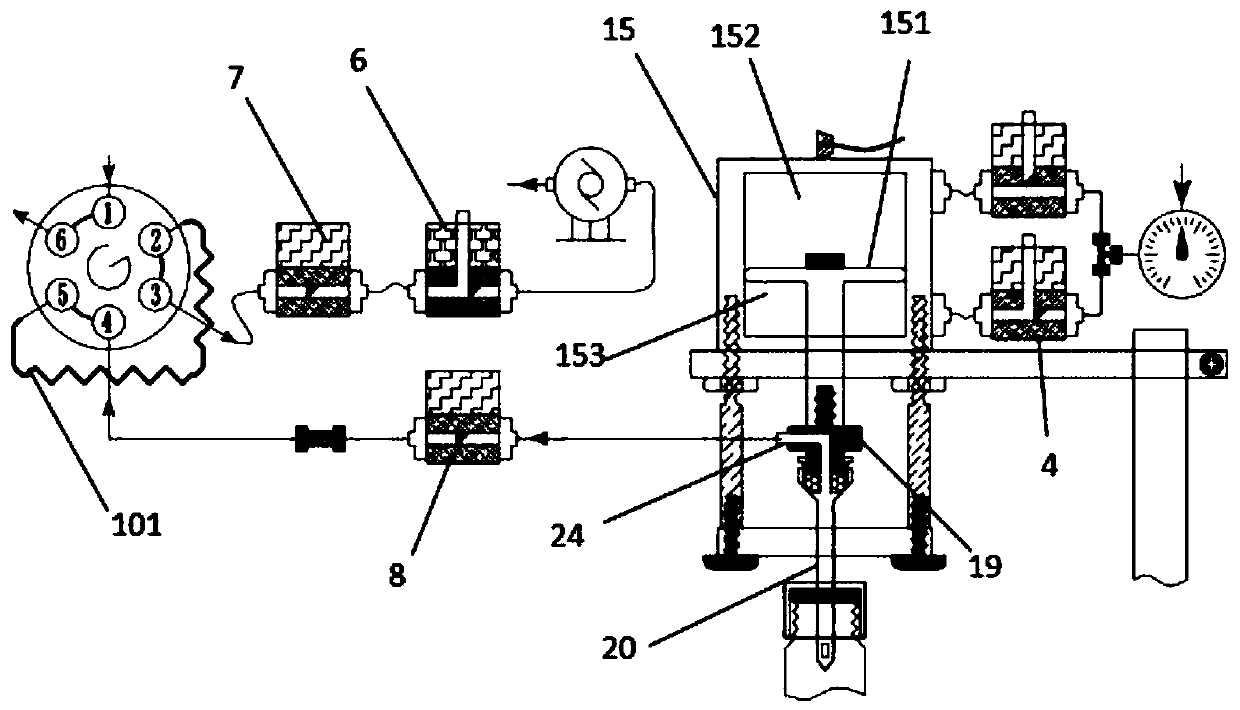

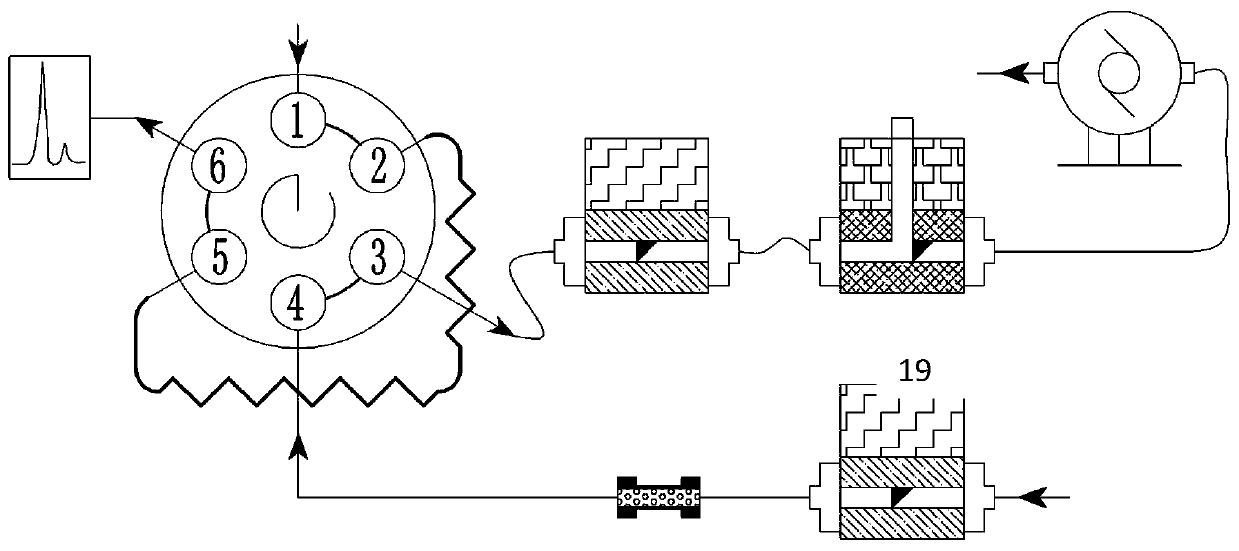

[0069] Such as Figure 1-7 Shown, the main components of the device of the present invention:

[0070] 1) Control system: mainly includes control panel 1 and single-chip microcomputer 2 (designed and customized based on Hongjing STC12C5A); and control panel 1, motor 26 (planetary gear motor), six-way sampling valve 10, vacuum pump 9, two-way outlet valve 7 , two-way intake valve 8, three-way exhaust valve 6, gas chromatograph 11, needle position probe 21, three-way needle inlet valve 3, three-way needle withdrawal valve 4, upper sliding piece 221 and lower sliding piece 222 respectively with conductive wire It is connected with the single-chip microcomputer 2, and is controlled by the program in the single-chip microcomputer 2. The control panel 1 is connected with the single-chip microcomputer 2 by a flat cable, on which there is a liquid crystal screen to display information and keys to input parameters or commands. The end position probe, the start position probe and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com