A kind of saturable absorber for fiber laser and preparation method thereof

A fiber laser and absorber technology, used in lasers, laser parts, phonon exciters, etc., to achieve the effects of good durability, high light damage threshold, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A preparation method of a saturable absorber for a fiber laser, comprising the following steps:

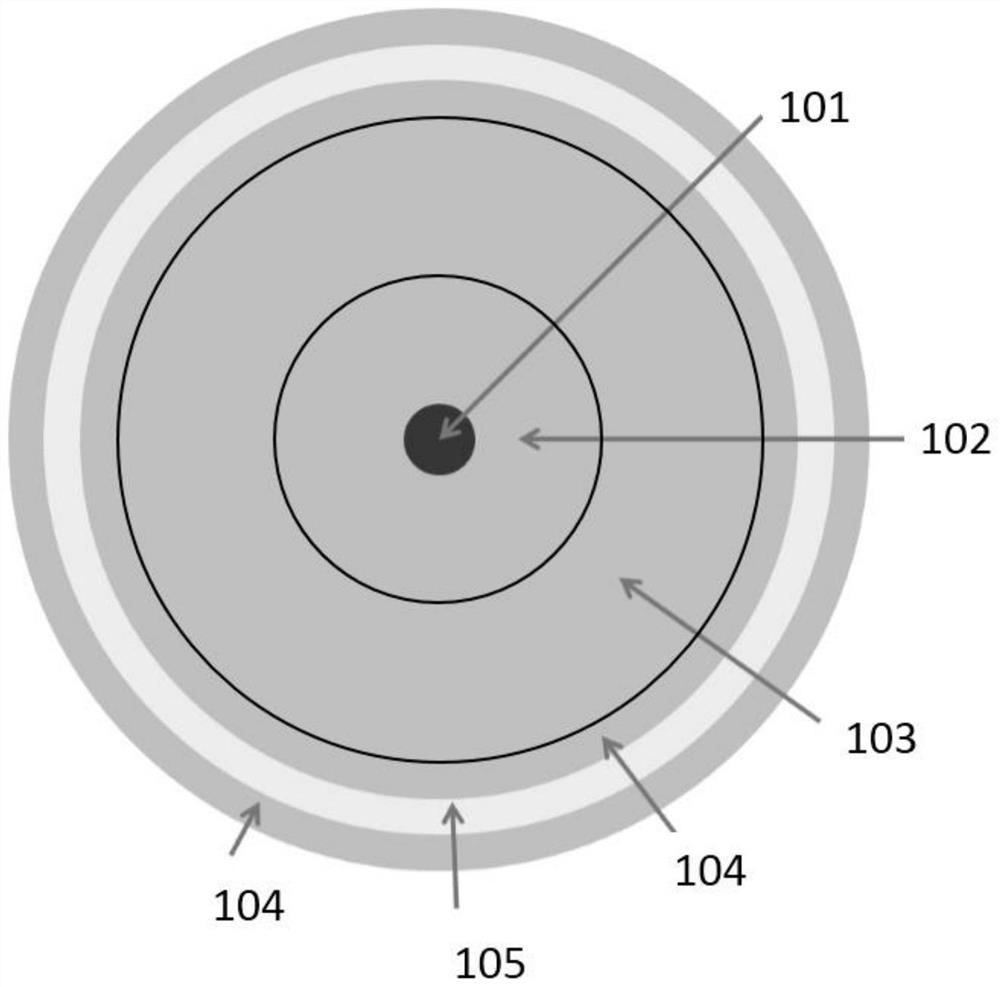

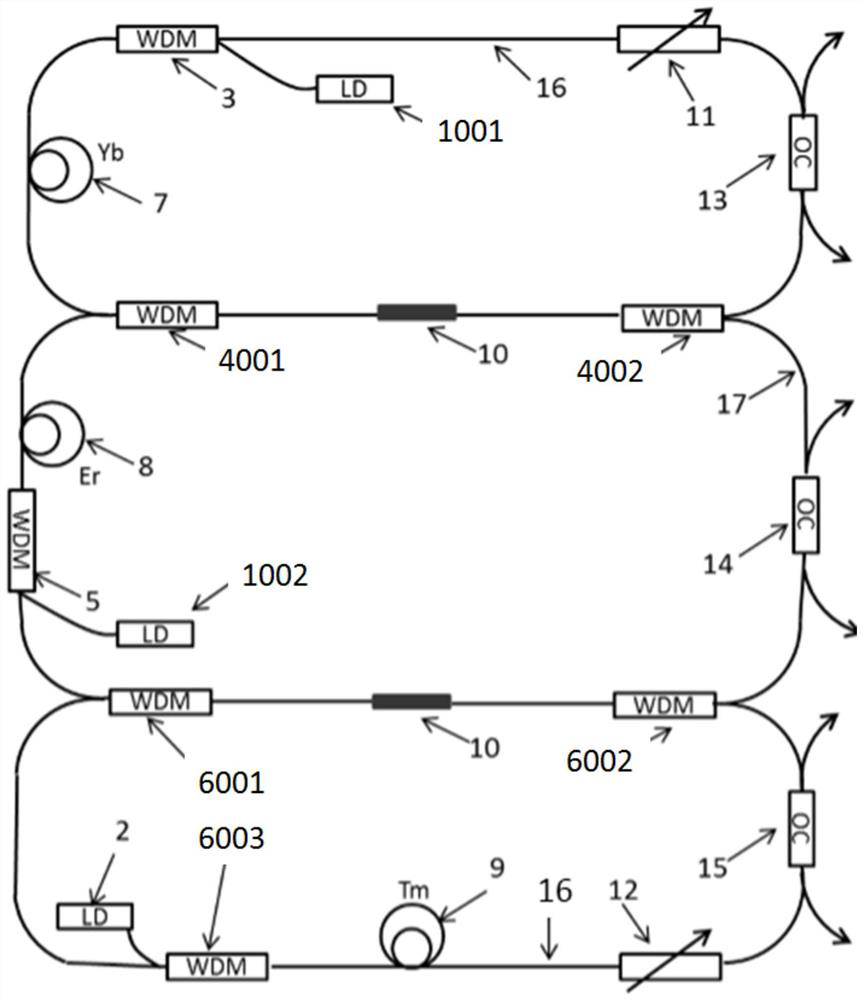

[0048] (1) After the core 101 is coated with the SMF-28e single-mode fiber 16 or HI 1060 single-mode fiber 17 of the cladding 102 and the coating layer 103, it is tapered, so that the beam waist in the middle of the single-mode fiber occurs, and it is drawn Tapered single-mode fiber; the diameters of SMF-28e single-mode fiber 16 and HI 1060 type single-mode fiber 17 are both 245 μm;

[0049] (2) Obtain layered graphene solution and Bi by liquid phase exfoliation 2 Te 3 solution; layered graphene solution and Bi 2 Te 3 The solution concentration is about 1mg / mL;

[0050] (3) First fix the tapered single-mode fiber, then pass the laser into the tapered single-mode fiber, then drop the graphene solution on the beam waist area of the tapered single-mode fiber, finally remove the laser, and heat the graphene solution Evaporate to realize the cladding of the graphene layer...

Embodiment 2

[0074] The difference from Example 1 is that in the preparation method step (1), the diameter of the single-mode fiber is 230 μm; in the step (2), the concentration of the layered graphene solution is 0.5 mg / mL, Bi 2 Te 3 The solution concentration is 2 mg / mL; the laser power in step (3) is 10 mW; the laser power in step (4) is 50 mW.

[0075] The prepared saturable absorber for fiber laser, refer to figure 2 , the diameter of the tapered single-mode optical fiber is 10 μm, and the thickness of the heterojunction layer is 5 μm. The thickness of the cladding layer 102 is 2 μm, and the material of the coating layer 103 is polyallyl diglycol carbonate resin, and the thickness is 3 μm.

Embodiment 3

[0077] The difference from Example 1 is that in the preparation method step (1), the diameter of the single-mode fiber is 260 μm; in the step (2), the concentration of the layered graphene solution is 2 mg / mL, Bi 2 Te 3 The solution concentration is 0.5mg / mL; the laser power in step (3) is 50mW; the laser power in step (4) is 10mW.

[0078] The prepared saturable absorber for fiber laser, refer to figure 2 , the diameter of the tapered single-mode fiber is 20 μm, and the thickness of the heterojunction layer is 15 μm. The thickness of the cladding layer 102 is 3 μm, and the material of the coating layer 103 is polyallyl diglycol carbonate resin with a thickness of 2 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com