Integrated injection implementation method and device of injectable bone substitute in vertebral body molding

A bone substitute and vertebral body shaping technology, which is applied in the field of surgical instruments and devices, can solve the problems of non-fixed space structure, extremely high operating skills, and complicated steps, so as to prevent leakage risks, avoid leakage risks, and shorten the The effect of operating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

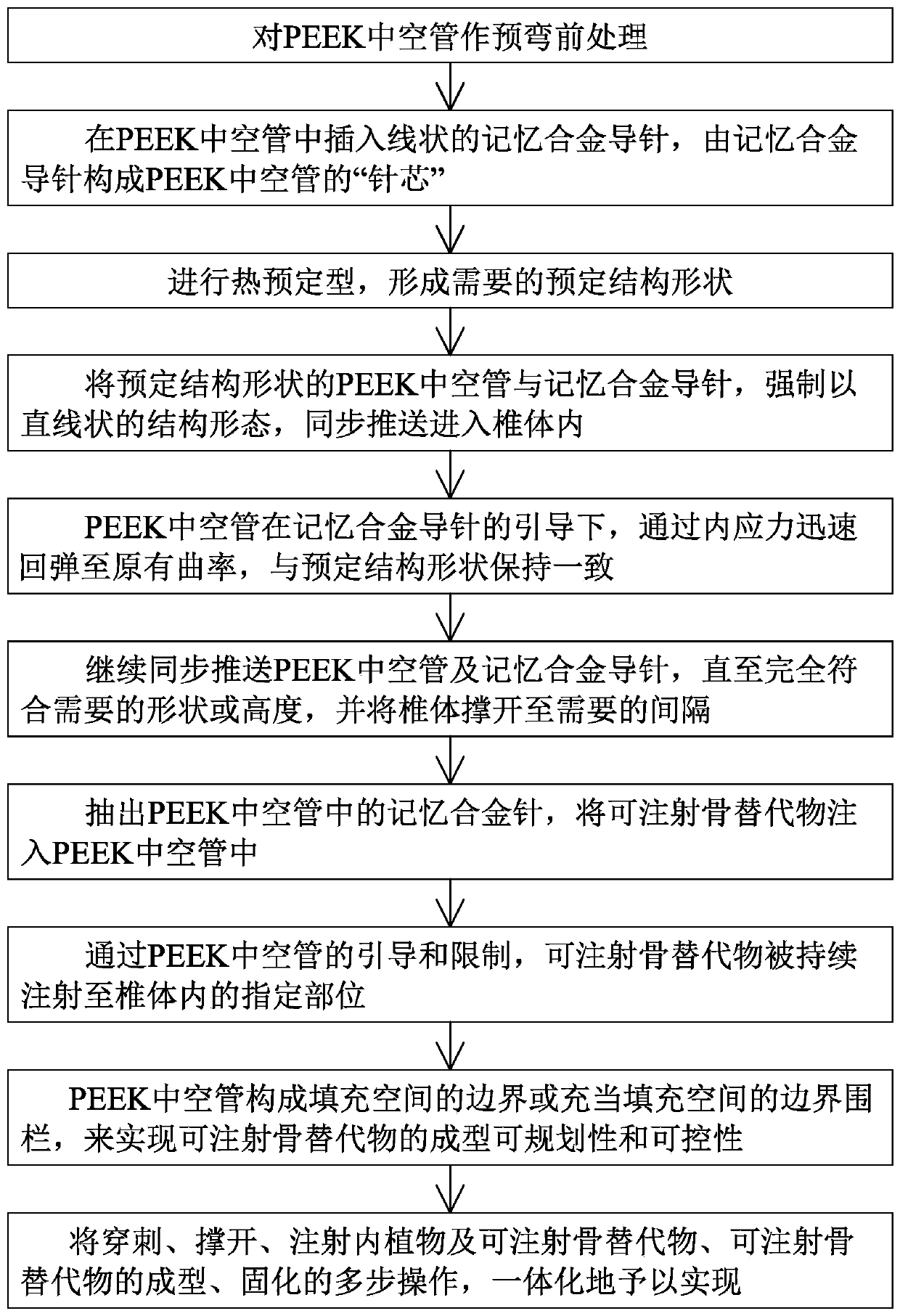

Method used

Image

Examples

Embodiment 1

[0109] 1. Preparation of materials:

[0110] a) Select PEEK thin-walled tubing as the biocompatible polymer hollow tube:

[0111] The pipe has an outer diameter of about 4mm and a thickness of about 1.5mm.

[0112] b) PEEK pipe pre-bending pre-treatment:

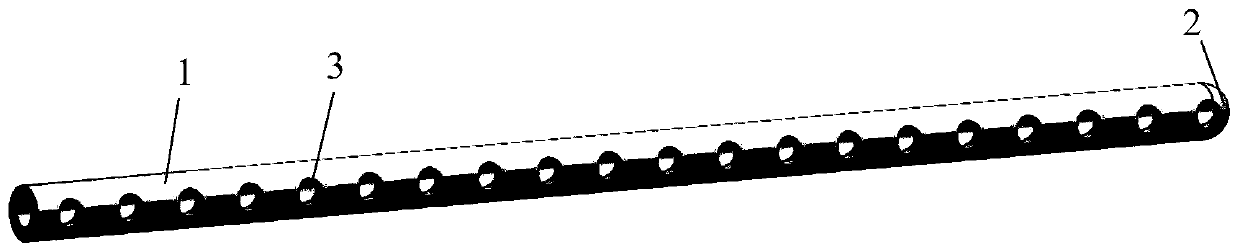

[0113] i. The starting end or the first end (that is, the end injected into the vertebral body O) of the biocompatible polymer hollow tube 1 is sealed, and a closed end 2 is formed at its front end (such as figure 2 shown in ).

[0114] ii. Drill holes on the inner side of the tubing to form the inner hole 3, the diameter of the inner hole matches the flow of the bone cement, about 2mm. Since the starting end is closed, after the bone cement is injected into the tubing, it can be injected into the inner space of the helical tubing through the inner hole.

[0115] iii. Make circular cutting or serpentine cutting on the surface of the pipe, and form a circular, serpentine or helical cutting groove 4 on the outer surface o...

Embodiment 2

[0157] The basic idea to solve the problem:

[0158] Combining the basic principles of tunnel shield machine / heading machine and flexible shaft drill, the spiral tunnel is continuously excavated in the vertebral body; then the drill bit is withdrawn from the flexible shaft tube, and the degradable part of the flexible shaft tube is retained in the tunnel , and finally inject the bone cement into the degradable flexible shaft tube to complete the bone cement shield of the spiral tunnel.

[0159] Specifically, its implementation process is as follows:

[0160] 1) Flexible shield system guided by memory alloy guide pin (also known as guide wire):

[0161] a. The system consists of a head drill 20 (participating Figure 16 shown in ), the flexible flexible shaft tube in the middle, and the driving device (not shown in the figure) at the tail are composed together.

[0162] b. The flexible flexible shaft tube part is divided into four layers: the outer layer is a degradable tube...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com