PE wrapping film and preparation method thereof

A wrapping film, linear low-density technology, applied in the field of PE wrapping film and its preparation, can solve the problems of low tensile strength and tear strength of PE wrapping film, improve processing performance, improve mixing uniformity, and improve tensile strength. The effect of tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

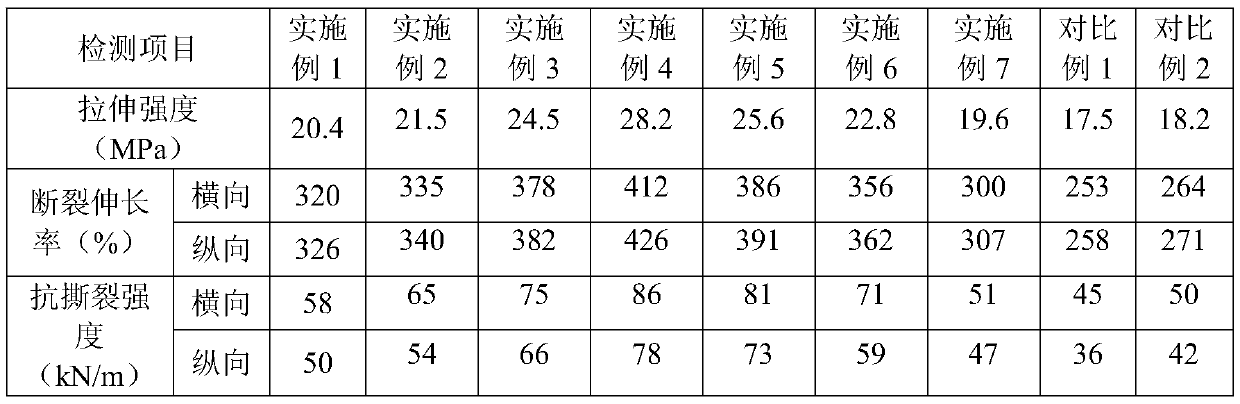

Examples

Embodiment 1

[0041] The PE stretch film of this embodiment is made of the following raw materials: 60 kg of linear low density polyethylene, 5 kg of metallocene linear low density polyethylene, 0.3 kg of sodium methyl silanolate, 0.3 kg of sodium alkylbenzene sulfonate, and nanometer calcium carbonate 0.2kg, carboxymethyl cellulose 0.3kg, methyl cellulose 0.2kg, polystyrene caprolactam 0.3kg, polythiazole 0.3kg, nano titanium dioxide 0.4kg.

[0042] The preparation method of the PE stretch film of the present embodiment comprises the following steps:

[0043] a. Add the materials into the mixer according to the formula, and stir and mix for 50 minutes at a speed of 500r / min to obtain the mixture;

[0044] b. Put the mixture in step a into the extruder to heat, melt and extrude at high temperature. The temperature of the first section of the extruder is 150°C, the temperature of the second section is 160°C, and the temperature of the third section is 180°C to obtain a molten body;

[0045...

Embodiment 2

[0048] The PE stretch film of this embodiment is made of the following raw materials: 70 kg of linear low density polyethylene, 6 kg of metallocene linear low density polyethylene, 0.8 kg of sodium methyl silanolate, 0.8 kg of sodium alkylbenzene sulfonate, and nanometer calcium carbonate 0.4kg, phosphocellulose 0.8kg, carboxymethylcellulose 0.8kg, methylcellulose 0.4kg, polystyrene caprolactam 0.5kg, polythiazole 0.5kg, nano-titanium dioxide 0.5kg.

[0049] The preparation method of the PE stretch film of the present embodiment comprises the following steps:

[0050] a. Add the materials into the mixer according to the formula, and stir and mix for 20 minutes at a speed of 550r / min to obtain the mixture; b. Put the mixture in step a into the extruder to heat and melt and extrude at high temperature. The first step of the extruder The temperature of the first stage is 160°C, the temperature of the second stage is 170°C, and the temperature of the third stage is 180°C to obtain...

Embodiment 3

[0054] The PE stretch film of this embodiment is made of the following raw materials: 80 kg of linear low density polyethylene, 8 kg of metallocene linear low density polyethylene, 1 kg of sodium methyl siliconate, 1 kg of sodium alkylbenzene sulfonate, 1 kg of nanometer calcium carbonate, Phosphocellulose 1kg, carboxymethylcellulose 1kg, methylcellulose 1kg, polystyrene caprolactam 0.8kg, polythiazole 0.8kg, nano-titanium dioxide 0.4kg.

[0055] The preparation method of the PE stretch film of the present embodiment comprises the following steps:

[0056] a. Add the materials into the mixer according to the formula, and stir and mix at a speed of 600r / min for 10 minutes to obtain the mixture; b. Put the mixture in step a into the extruder to heat and melt and extrude at high temperature. The first step of the extruder The temperature of the first stage is 155°C, the temperature of the second stage is 165°C, and the temperature of the third stage is 170°C to obtain a melt;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com